- All

- Cables

- Delivery

- Electronics

- Gearboxes

- Geared Motors

- Hygienic Washdown

- Motion Control

- Motor

- Power Tips

- Power Transmission

- Quality

- Rack and Pinion

- Service

- ServoStop Brake System

- STOBER

- System

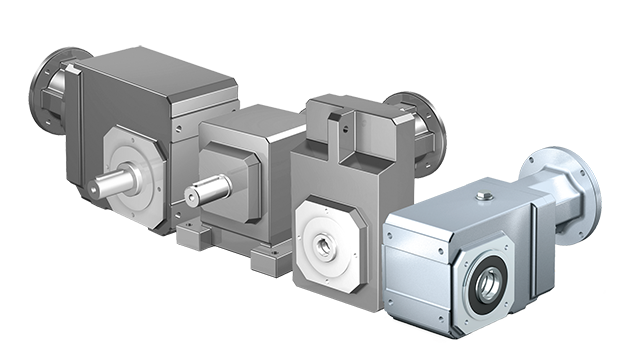

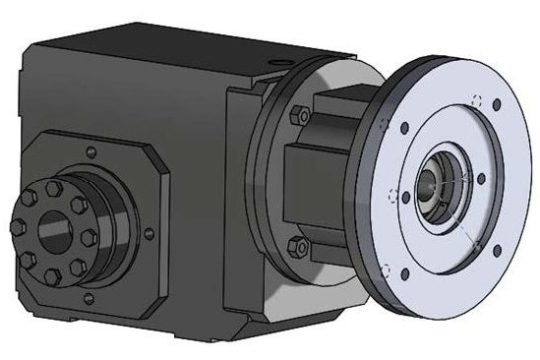

STOBER NEMA gearboxes deliver superior performance

Designed to provide the highest degree of resiliency and durability, STOBER’s NEMA gearboxes deliv...

Year in review: Top blog posts of 2024

We hope our blog has been informative, useful, and inspiring this year. As a review of 2024, we look...

Merry Christmas to all, and to all a good night!

Merry Christmas to all, and to all a good night!...

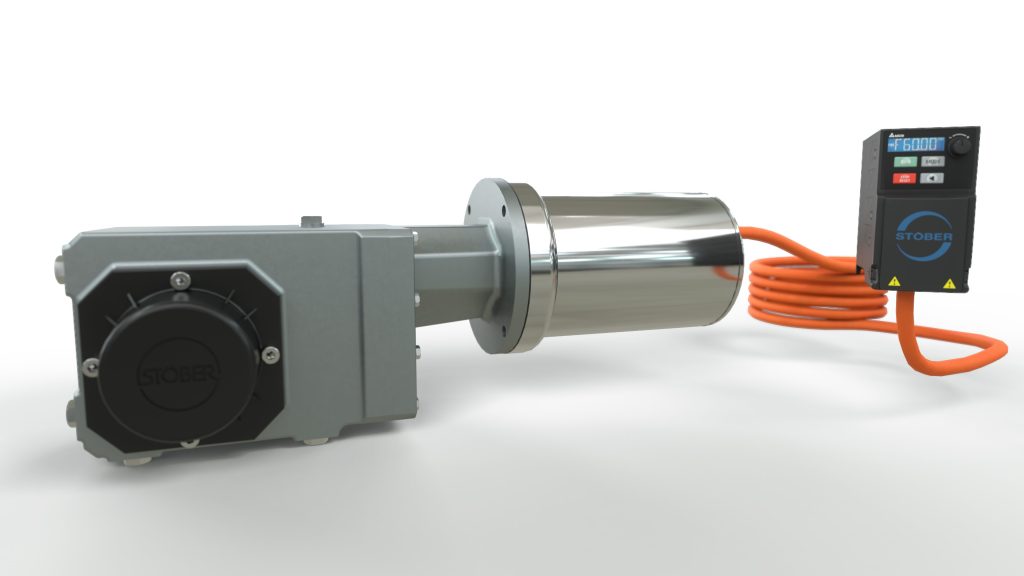

Motors 101: Permanent magnet motor technology featured in STOBER cLEAN System

Let's explore the different types of magnetic fields used in motors, the principles of induction mot...

STOBER announces new ZS Rack

While rack and pinion products are not new for STOBER, the new ZS Rack elevates STOBER’s rack and ...

STOBER unveils Apprenticeship 2.0 during National Apprenticeship Week

STOBER Drives has recently adapted an Apprenticeship 2.0 program, an expansion of the company’s ap...

STOBER participates in Women in Manufacturing event

Representatives from STOBER recently attended Women in Manufacturing events hosted by Maysville Comm...

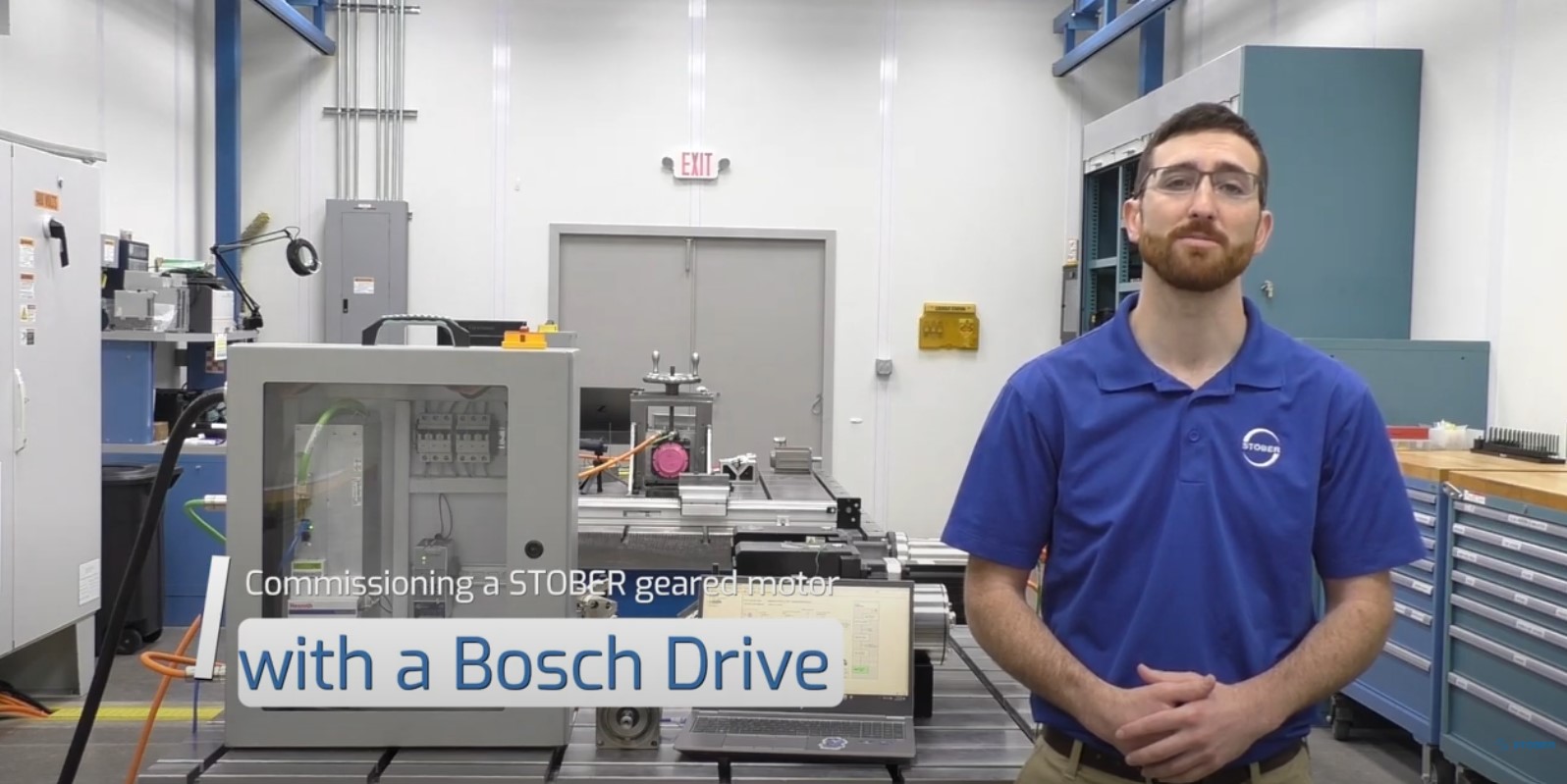

Commissioning a STOBER geared motor with a Bosch drive

Commissioning a STOBER geared motor with a Bosch drive is easier than you may think. Watch the vide...

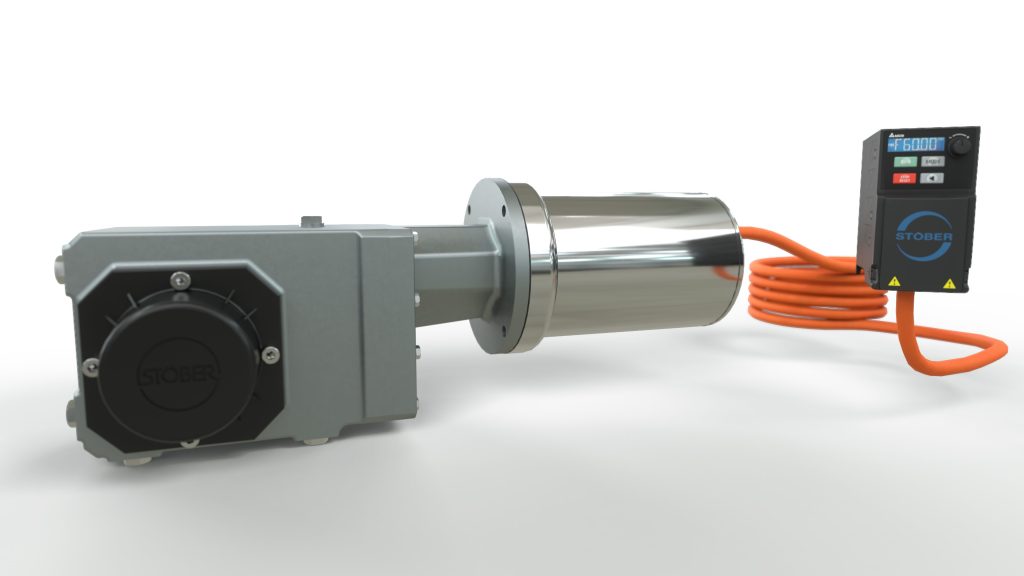

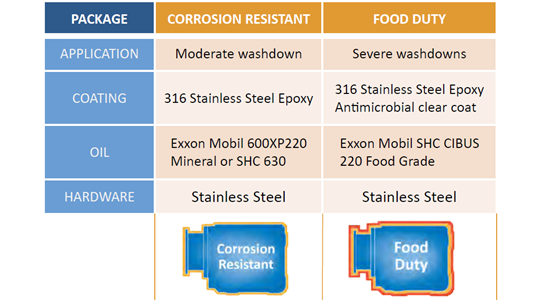

STOBER stainless steel options ideal for hygienic food production

STOBER has made it even easier for factories to maximize productivity and eliminate unplanned downti...

STOBER participates in student outreach at Mason County Career Magnet School

STOBER recently expanded outreach and student recruitment efforts is through partnership and support...

Scratch & win with STOBER in booth 1221 at Automation Fair

Connect with the STOBER team at Automation Fair in Anaheim to “scratch” the surface of learning ...

cLEAN System: The ultimate solution for food industry

STOBER is the world’s leading expert in solutions for the food processing industry, so it’s no s...

Commissioning a STOBER geared motor with a Siemens drive

Commissioning a STOBER geared motor with a Siemens drive is easier than you may think. Watch the vi...

STOBER Serves surpasses 100 hours of volunteer time, seeking additional opportunities

Through the STOBER Serves volunteer program, STOBER employees have recently contributed 100 hours to...

STOBER named Large Business of the Year by Maysville Area Chamber

STOBER Drives has been named Large Business of the Year by the Maysville Area Chamber of Commerce. �...

STOBER’s Family Market scheduled for Nov. 30

STOBER proudly employs many talented and creative individuals! We are excited to offer an opportuni...

STOBER servo geared motor increases machine efficiency

A recent project on a pepperoni slicer for an OEM customer proved successful and keeps pizza product...

Beyond parts: Supplier relationships determine project success for OEMs

STOBER’s commitment to clear and consistent communication provides peace of mind that comes with s...

Top 3 benefits of the STOBER cLEAN System

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s re...

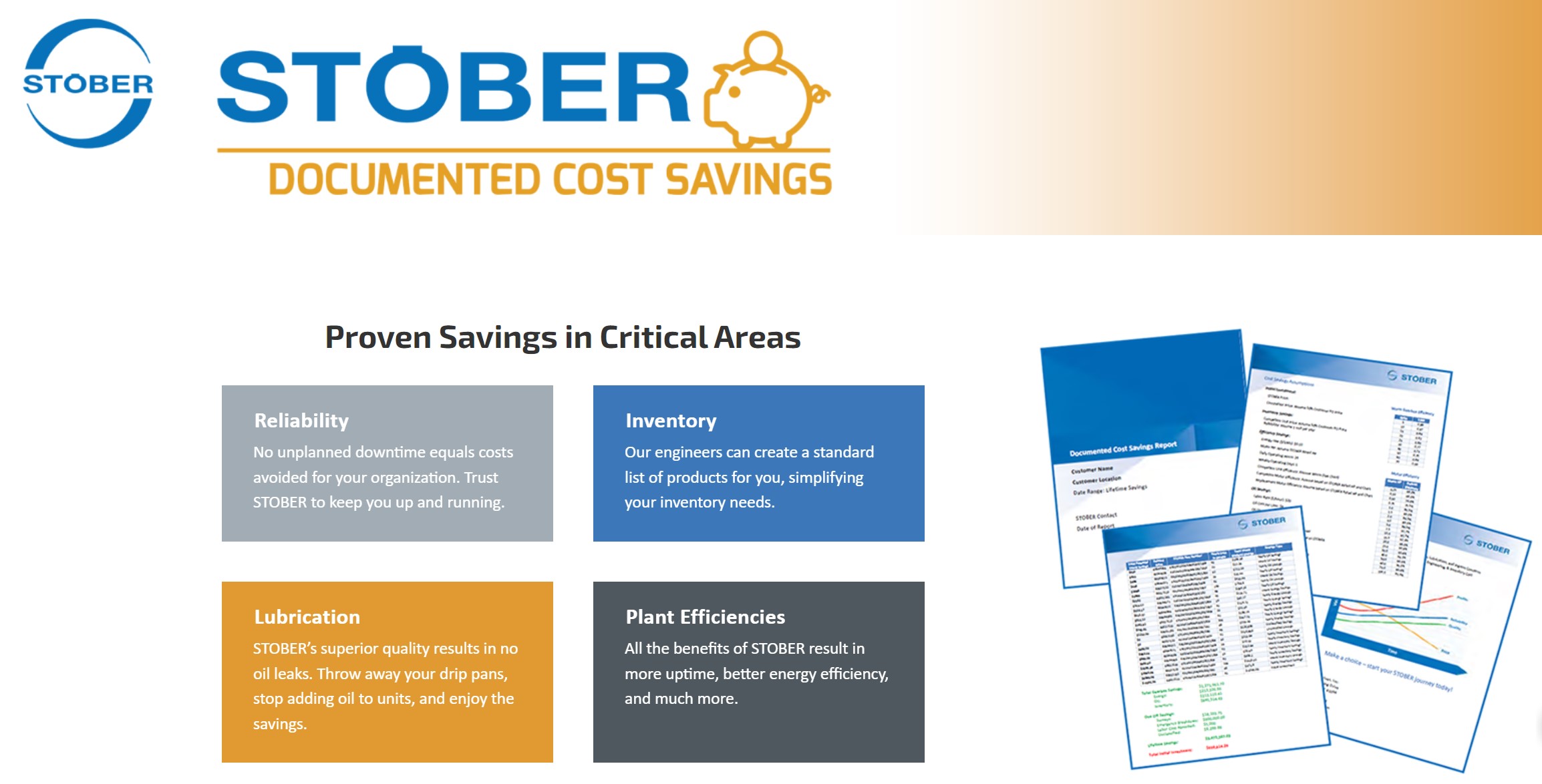

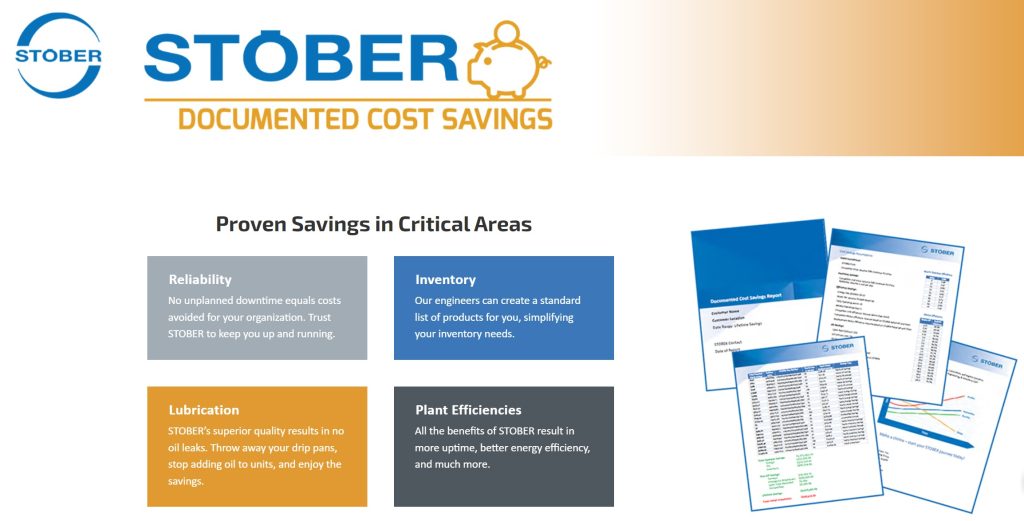

Let STOBER Documented Cost Savings calculate your expenditure reduction

It's well known that STOBER products last longer, require less maintenance, use less energy, and opt...

STOBER Oktoberfest Stein Dash Aug. 10

Join us at Maysville Oktoberfest on Saturday, Aug. 10 from 6 p.m. to 8 p.m. at the STOBER Stein Dash...

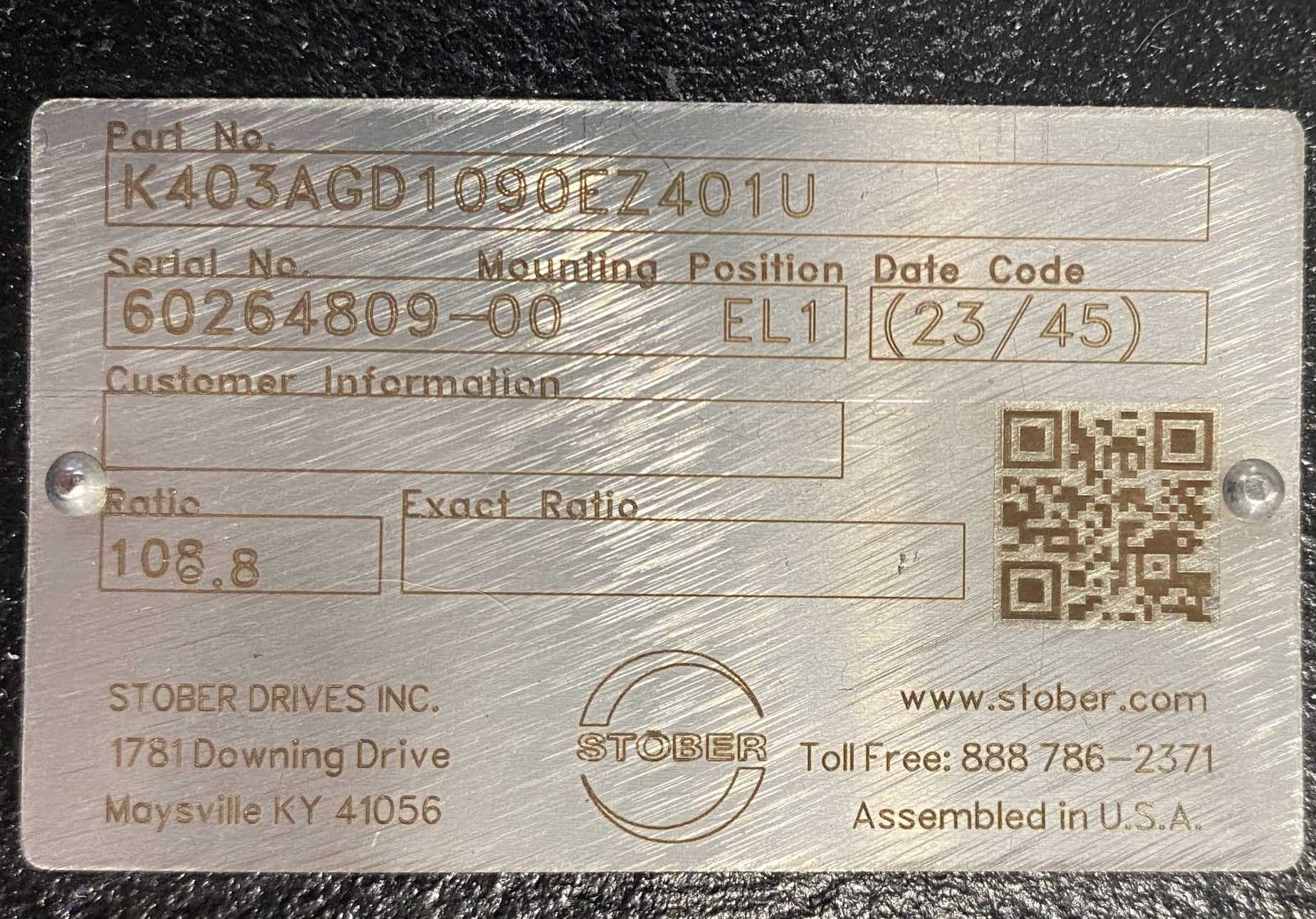

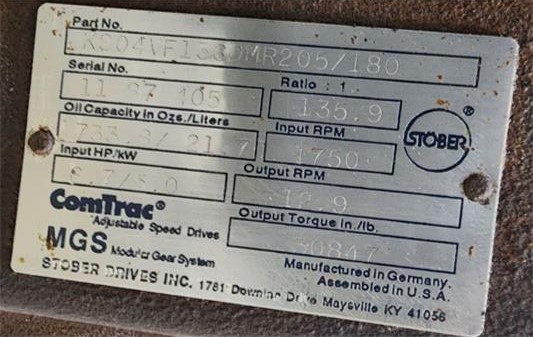

STOBER Product ID Tool helpful for setup, operation, and assembly

One of many tools and software options available from STOBER, the Product ID Tool is a central place...

Commissioning a STOBER geared motor with a Kollmorgen drive

Commissioning a STOBER geared motor with a Kollmorgen drive is easier than you may think. Watch the...

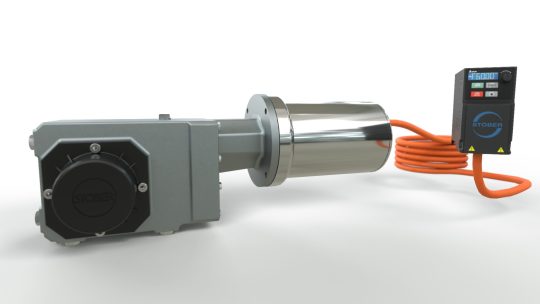

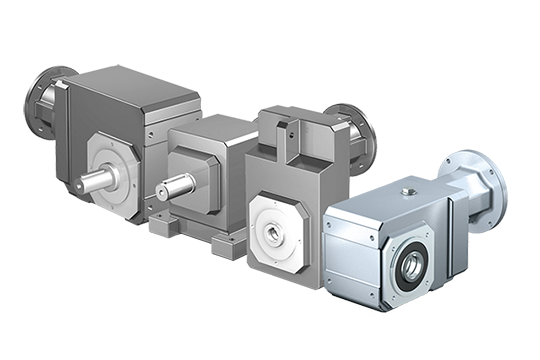

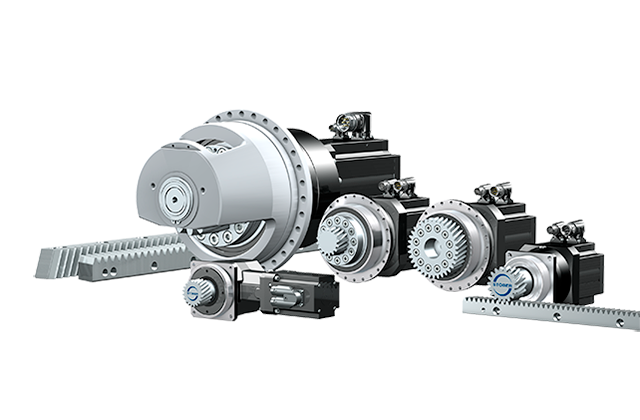

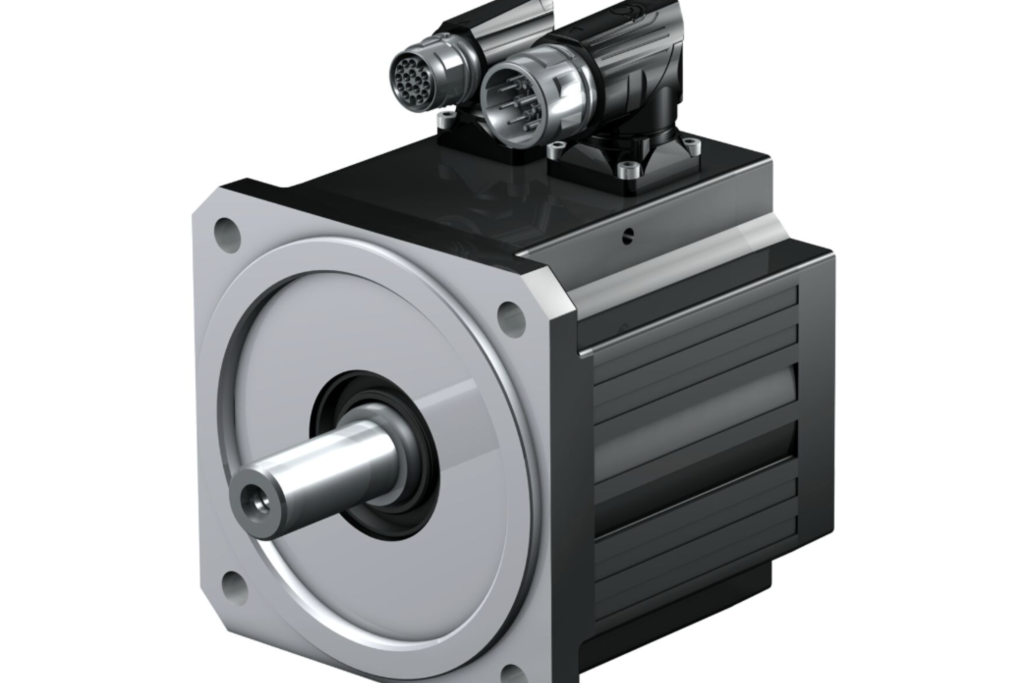

Range of STOBER motors provide solutions for your application

Inline geared motors, right angle geared motors, geared motors with rack and pinion, geared motors w...

Hidden savings in your storeroom: STOBER slashes inventory costs

Reduce storeroom inventory costs and boost efficiency with STOBER’s modular gearboxes and motors. Fewer SKUs, faster delivery, smarter design.

Customer success: Boosting uptime with STOBER food-duty solutions

Discover how a leading food processor improved uptime, cut maintenance costs, and reduced energy use by 66% with STOBER’s cLEAN System—featuring washdown-ready gearboxes and motors.

How to select the right servo motor for your application

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Cut energy costs without compromise: The STOBER cLEAN System advantage

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

The role of gearboxes in packaging line efficiency

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Happy Retirement, Shelley Duncan!

Shelley Duncan, a utility employee on the STOBER assembly team, has worked at STOBER for about three years and will be retiring on May 31.

Big Ass Fans names STOBER 2024 Supplier of the Year

STOBER Drives, Inc. was honored to accept the Big Ass Fans Supplier of the Year award for 2024.

What is a servo motor and how does it work?

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

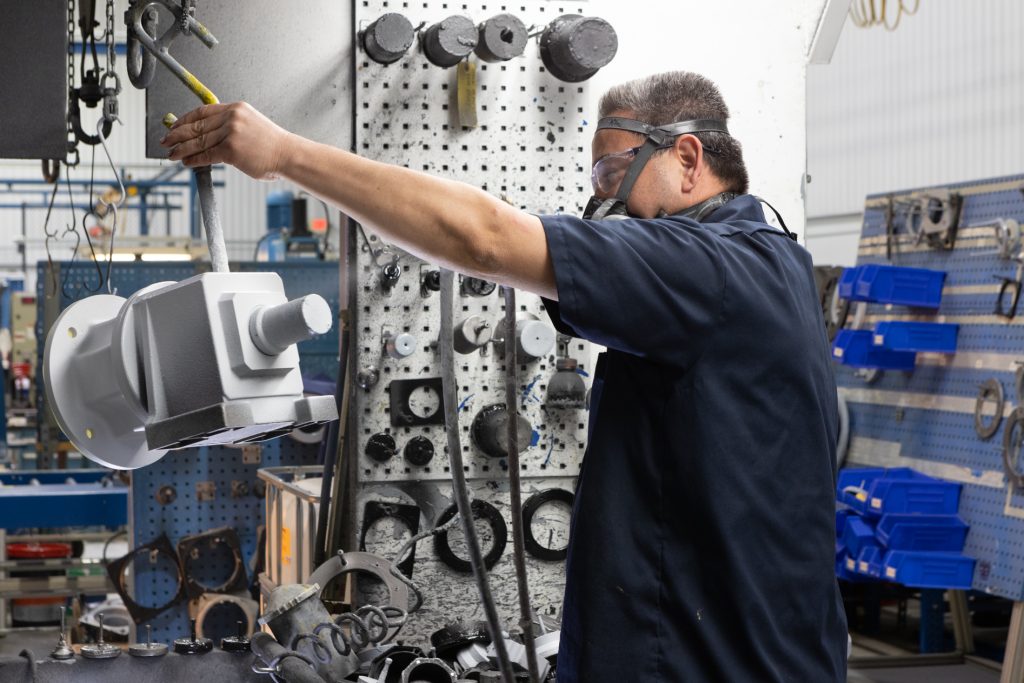

Comprehensive gear unit solutions: Installation, maintenance, and repair

Optimize performance with STOBER’s precision gear units. We offer expert installation, maintenance, and 24/7 repair services to minimize downtime.

Eight warning signs that you need industrial gearbox repair

Prevent costly breakdowns and extensive industrial gearbox repair by learning eight warning signs that indicate repair is needed.

What is a planetary gearbox and how does it work?

Uncover how planetary gearboxes work. Learn about their compact design, high torque, and efficiency, making them ideal for diverse industrial applications.

Keyed vs. keyless connections: What’s the difference and why does it matter?

While both keyed and keyless connections serve the same purpose of transmitting torque, they operate in fundamentally different ways. Understanding the distinctions between the two connection types can help you choose the best option for your systems.

2025 STOBER scholarship winners announced

The Ray Williams, Ashely Hurst, Mike Noel, and Logan Cooper Memorial Scholarship was established in remembrance of employees who passed away during their employment at STOBER. The scholarship program has awarded multiple $500 scholarships each year since 2016 to help students pursue their plans to attend college or trade school.

Don’t get caught with your plants down – rely on STOBER’s cLEAN System

Created to provide a long-lasting system that improves your plant’s reliability, STOBER’s cLEAN System is durable, efficient, and guaranteed to work in the harshest environments–it’s the world’s toughest system.

STOBER food-duty gearboxes and geared motors use antimicrobial coating

The Burke antimicrobial clear top coat featured on STOBER’s food-duty packaged products is proven to eliminate the spread of dangerous pathogens and infectious bacterial growth against more than 600 bacteria including legionella, salmonella, e-coli, staph, and more.

STOBER employees deliver donations to flood victims in Floyd County

Floyd County, Kentucky, was severely impacted by a historic flood in February when the Levisa Fork of the Big Sandy River crested at 43.35 feet. The flooding, caused by excessive rainfall, prompted officials to declare a state of emergency as residents were trapped in vehicles and homes and more than 300 flood-related calls came into…

STOBER a proud member of Rockwell Automation PartnerNetwork

The Rockwell Automation PartnerNetwork provides customers with an integrated team of engineering specialists and suppliers that are leaders in the automation and manufacturing industry. STOBER is a proud Technology Partner in the Rockwell Automation PartnerNetwork.

cLEAN up your act with STOBER’s cLEAN System

The new STOBER cLEAN System is hygienically designed, making it the ultimate solution for food processing.

STOBER Serves volunteers share the love at Buffalo Trace Emergency Shelters

Several STOBER Serves volunteers recently gathered at the Buffalo Trace Emergency Shelters to help remove debris and clean & paint the interior of the shelters.

New comic in the Gerhardt Guide

Drumroll, please! We’ve added a mew comic to The Gerhardt Guide, a comic series about adventures in the life of Gerhardt Gearhead!

STOBER cLEAN System named “Best of the Best” at IPPE

The STOBER cLEAN System was named “Best of the Best” recipient at the 2025 International Production & Processing Expo (IPPE).

World’s toughest gearbox doesn’t require oil changes

Did you know that the world’s toughest gearbox doesn’t require oil changes? STOBER’s KSS stainless steel, K, C, and F series reducers (in food-duty or corrosion-resistant options) require no maintenance due to efficient gearing, housing design, quality components, and expert assembly.

cLEAN Drive: Easy to install, easy to use

STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

STOBER NEMA gearboxes deliver superior performance

Designed to provide the highest degree of resiliency and durability, STOBER’s NEMA gearboxes deliver superior performance that can revolutionize how well equipment functions across numerous processes and industries.

Year in review: Top blog posts of 2024

We hope our blog has been informative, useful, and inspiring this year. As a review of 2024, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

Merry Christmas to all, and to all a good night!

Merry Christmas to all, and to all a good night!

Motors 101: Permanent magnet motor technology featured in STOBER cLEAN System

Let’s explore the different types of magnetic fields used in motors, the principles of induction motors, and the innovative permanent magnet technology featured in STOBER’s cLEAN motor.

STOBER announces new ZS Rack

While rack and pinion products are not new for STOBER, the new ZS Rack elevates STOBER’s rack and pinion offerings.

STOBER unveils Apprenticeship 2.0 during National Apprenticeship Week

STOBER Drives has recently adapted an Apprenticeship 2.0 program, an expansion of the company’s apprenticeship program that began in 2006.

STOBER participates in Women in Manufacturing event

Representatives from STOBER recently attended Women in Manufacturing events hosted by Maysville Community and Technical College.

Commissioning a STOBER geared motor with a Bosch drive

Commissioning a STOBER geared motor with a Bosch drive is easier than you may think. Watch the video for step-by-step instructions.

STOBER stainless steel options ideal for hygienic food production

STOBER has made it even easier for factories to maximize productivity and eliminate unplanned downtime with the cLEAN System. STOBER’s cLEAN System eliminates premature failure due to water ingress, has IE5 energy efficiency, and is designed to EHEDG standards.

STOBER participates in student outreach at Mason County Career Magnet School

STOBER recently expanded outreach and student recruitment efforts is through partnership and support with the Mason County Career Magnet school.

Scratch & win with STOBER in booth 1221 at Automation Fair

Connect with the STOBER team at Automation Fair in Anaheim to “scratch” the surface of learning about STOBER’s solutions for your application! Scratch a ticket to win a cool prize in booth 1221 during Automation Fair Nov. 18-21!

cLEAN System: The ultimate solution for food industry

STOBER is the world’s leading expert in solutions for the food processing industry, so it’s no surprise that the cLEAN System is the ultimate solution for harsh washdown environments.

Commissioning a STOBER geared motor with a Siemens drive

Commissioning a STOBER geared motor with a Siemens drive is easier than you may think. Watch the video for step-by-step instructions.

STOBER Serves surpasses 100 hours of volunteer time, seeking additional opportunities

Through the STOBER Serves volunteer program, STOBER employees have recently contributed 100 hours to beautifying Cummins Nature Preserve. The company is seeking additional volunteer opportunities for its employees.

STOBER named Large Business of the Year by Maysville Area Chamber

STOBER Drives has been named Large Business of the Year by the Maysville Area Chamber of Commerce.

STOBER’s Family Market scheduled for Nov. 30

STOBER proudly employs many talented and creative individuals! We are excited to offer an opportunity to showcase their artistic and innovative crafts & businesses through a community-wide shopping event!

STOBER servo geared motor increases machine efficiency

A recent project on a pepperoni slicer for an OEM customer proved successful and keeps pizza production as efficient as possible, speeding up the process while eliminating downtime.

Beyond parts: Supplier relationships determine project success for OEMs

STOBER’s commitment to clear and consistent communication provides peace of mind that comes with seamless collaboration and transparent updates, allowing OEMs to focus on core business objectives while STOBER handles the details.

Top 3 benefits of the STOBER cLEAN System

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

Let STOBER Documented Cost Savings calculate your expenditure reduction

It’s well known that STOBER products last longer, require less maintenance, use less energy, and optimize the plant floor. But don’t just take our word for it–use our Documented Cost Savings tool to calculate just how much your company could save by using STOBER.

STOBER Oktoberfest Stein Dash Aug. 10

Join us at Maysville Oktoberfest on Saturday, Aug. 10 from 6 p.m. to 8 p.m. at the STOBER Stein Dash!

STOBER Product ID Tool helpful for setup, operation, and assembly

One of many tools and software options available from STOBER, the Product ID Tool is a central place for customers to look up installation, operation, and assembly instructions.

Commissioning a STOBER geared motor with a Kollmorgen drive

Commissioning a STOBER geared motor with a Kollmorgen drive is easier than you may think. Watch the video for step-by-step instructions.

Range of STOBER motors provide solutions for your application

Inline geared motors, right angle geared motors, geared motors with rack and pinion, geared motors with fans, geared motors with brakes – STOBER has the range you need for your application.

STOBER’s cLEAN System earns IP68 certification

The STOBER KSS gearbox and cLEAN Motor recently received IP68 certification in addition to the already-existing IP69K certification, IE5 energy efficiency, and design to EHEDG standards.

STOBER closed July 4 and July 5; emergency support available

STOBER will be closed on Thursday, July 4 in celebration of Independence Day, and on Friday, July 5 as a company-wide wellness day.

Best Places to Work in Kentucky recognizes STOBER Drives, Inc.

The ranked list of 2024 Best Places to Work in Kentucky has been released and STOBER Drives, Inc. is proud to have placed 21st in the category of medium companies comprised of 150-499 employees. A group of STOBER employees accepted the award at a ceremony on June 13.

STOBER service saves the day for food processing customer

STOBER has a service mentality to make sure our customer application solutions run flawlessly. Learn more about a recent customer’s experience.

STOBER’s solutions for the poultry industry

Poultry processing can be a messy business, but STOBER products are able to withstand the toughest cleaning regiments, including IP69K. Plus, our industry-leading warranty gives you the peace of mind that the next routine washdown won’t cause major downtime.

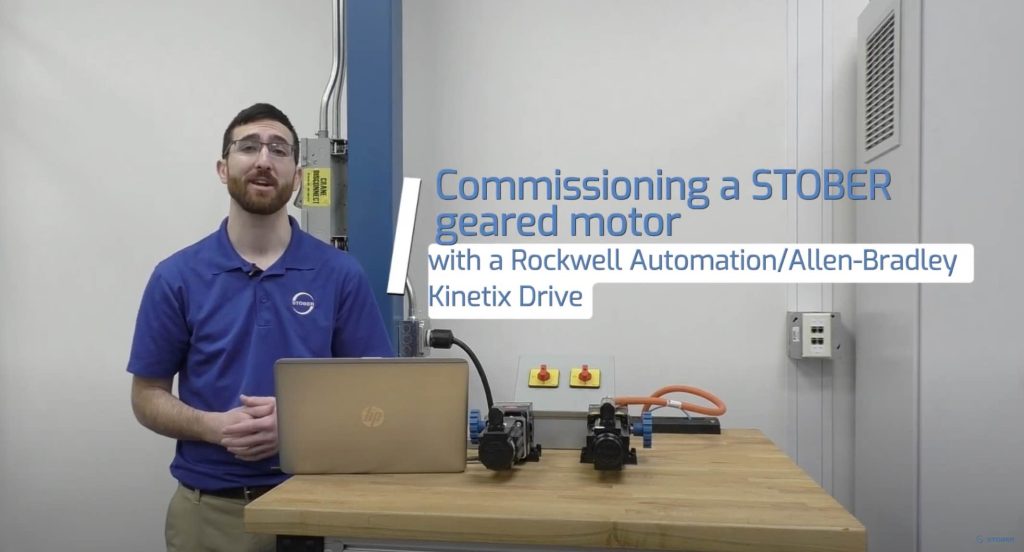

Commissioning a STOBER geared motor with Rockwell Automation/Allen-Bradley drive

Commissioning a STOBER geared motor with a Rockwell Automation/Allen-Bradley drive is easier than you may realize. Watch the video for step-by-step instructions.

Reduced backlash options now assembled in Maysville, Ky.

STOBER is proud to announce reduced backlash options are now assembled in Maysville, Ky., meaning they’ll be available in just days, not months!

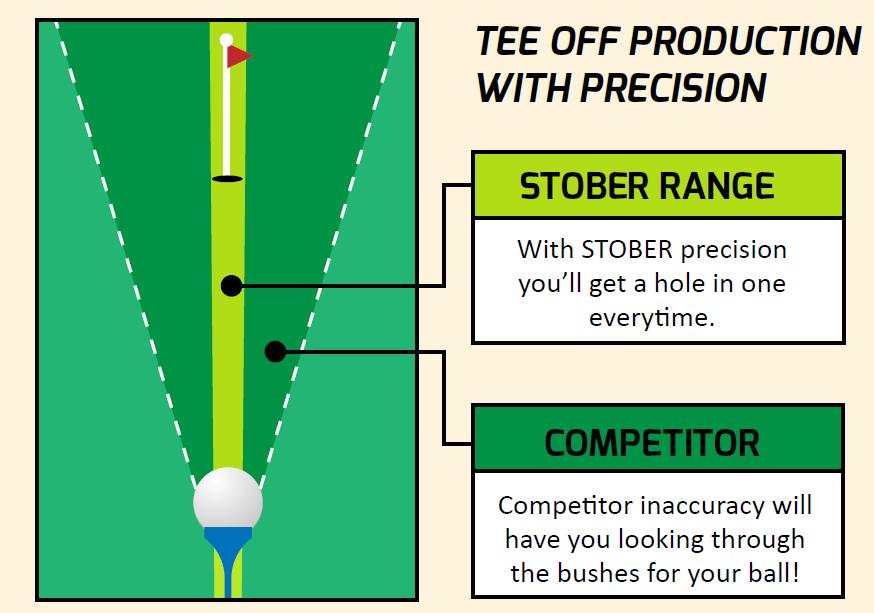

STOBER Memorial Golf Scramble a success

On Saturday, May 18, STOBER hosted a memorial golf scramble at Kenton Station Golf Course. Proceeds from the scramble established scholarship funds for relatives of two employees who recently passed away unexpectedly.

STOBER gearbox performs for 27 years

In 1997, a snack food manufacturer installed a STOBER K8 gearbox in their facility. The particular gearbox broke down recently, after 27 years of life.

STOBER Drives signing new class of apprentices

Congratulations to STOBER Drives’ newest class of apprentices who recently signed to continue their employment and education.

Optimize without compromise: Space-saving inline solutions from STOBER

Don’t get stuck in a solution—find the best fit! STOBER’s inline planetary geared motor solution takes up less space in your machine footprint than a right-angle planetary solution.

Gearing up for success: Installation training at food processing plants

The STOBER team takes a hands-on approach to help maintenance crews learn to install STOBER equipment on their food production lines.

STOBER Memorial Golf Scramble to be held May 18

In memory of Mike Noel and Logan Cooper, STOBER is hosting a golf scramble at Kenton Station Golf Course on Saturday, May 18. All proceeds from the event go toward a scholarship fund for Mike’s grandson and Logan’s two sons.

Happy Retirement, Billie Wallingford!

Billie Wallingford, a machinist on our manufacturing team, has worked at STOBER for more than 10 years and will be retiring on April 26.

STOBER offers the ultimate solutions for the cheese industry

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the acidic nature of cheese.

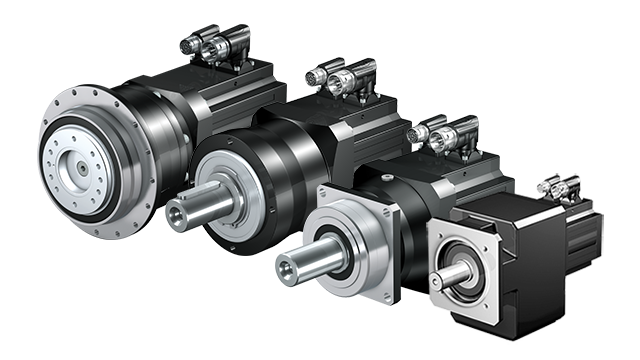

Most compact planetary geared motors just got better

The most compact planetary geared motors on the market just got better. Now with a space-saving design, STOBER’s PH9-12 Generation 4 products feature lower weight, lower mass inertia, higher rigidity, and up to 20 percent more torque. Plus, the reducer interface is 100 percent compatible to the previous generation!

STOBER named 2024 Best Places to Work in Kentucky

STOBER Drives, Inc. is honored to be named to the 2024 list of Best Places to Work in Kentucky for medium-sized businesses.

STOBER scholarship winners announced

STOBER Drives has named Rypli Donahue, Brenna Harris, and Taylor Watts winners of the 2024 Ashley Hurst, Ray Williams and Mike Noel Memorial Scholarship.

STOBER superior in meat processing equipment

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

STOBER a proud Rockwell Automation Partner

STOBER is proud to be a member of the Rockwell Automation PartnerNetwork as part of an integrated team of engineering specialists and suppliers.

What makes a product IP69K certified?

IP69K rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

Feil honored by MCTC

Maysville Community & Technical College (MCTC) recently honored STOBER General Manager Peter Feil for his service to their Board of Directors. Feil said he is very grateful for having had the opportunity to serve on the MCTC Board.

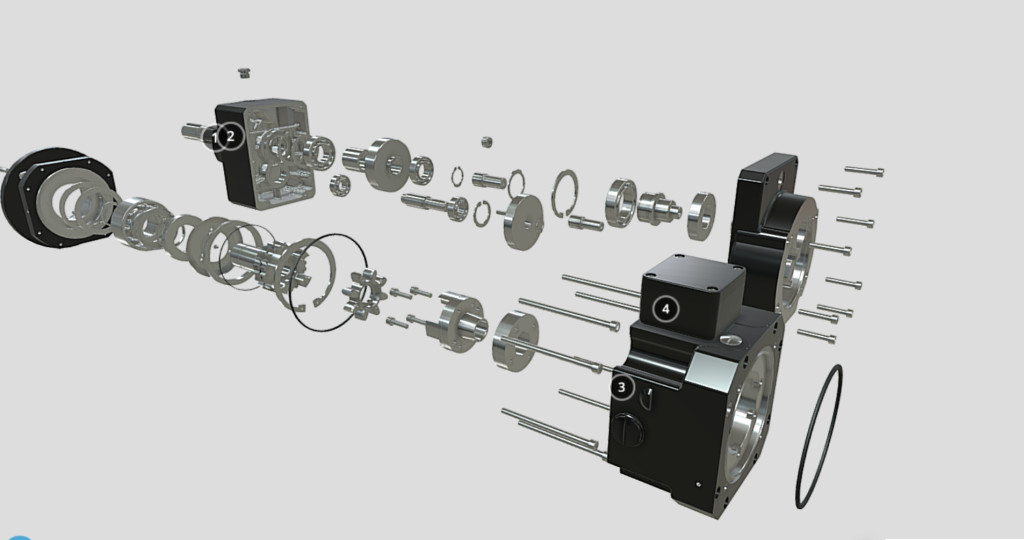

ServoStop safety brake 3D models available

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gearboxes, you’re in luck—3D models of the product are now available on the STOBER website!

STOBER features plug-and-play compatibility with popular drive brands

STOBER motors and geared motors are flexible in design and compatibility with third-party drives.

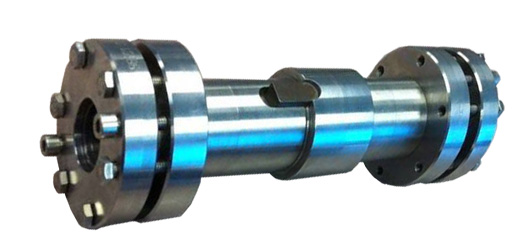

STOBER wobble-free bushing allows interchangeable mounting

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.

Introducing the STOBER cLEAN System

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

STOBER motors ready to ship from Maysville, Ky.

Are you frustrated with lead times for motors? STOBER has several options readily available from Maysville, Ky. Our Kentucky facility stocks the EZ3 (72mm frame size), EZ4 (98mm), EZ5 (115mm), and EZ7 (145mm) motors.*

Packaged synchronous servo geared motors from STOBER

Did you know STOBER’s synchronous servo geared motors are a packaged solution? Yep, you can be back up and running faster than ever because with STOBER’s packaged solution, installation is easy.

Year in review: Top blog posts of 2023

We hope our blog has been informative, useful, and inspiring this year. As a review of 2023, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

STOBER featured in new Christmas movie

You’ve probably noticed the new Christmas movie, “Candy Cane Lane” on Amazon Prime. Did you know that it stars a STOBER gearbox!?

STOBER sales team volunteers at Maysville Hands of Hope

STOBER sales team recently volunteered to help sort donations, hang clothing, and serve lunch to shoppers who visited Maysville Hands of Hope.

OEM Renewal Program extends machine life

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

STOBER solutions for food production

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

STOBER drives innovation for packaging OEMs

STOBER solutions can reduce space requirements in the packaging industry and minimize components and maintenance—a win-win situation! Innovative designs from STOBER can reduce equipment footprint by 20 percent.

STOBER’s paint process prevents flaking

STOBER’s quality paint mixture and painting process eliminates any worry about paint flaking. Every food duty unit is washed to remove any grease that could prevent paint from properly adhering to the surface. Then, each unit is painted with four layers of paint, including an antimicrobial clear coat.

Application benefits of using a STOBER geared motor

STOBER geared motors feature options for your application’s right fit – right angle or inline, helical or planetary, encoder options, brakes, and fans.

Satisfied distributor recognizes STOBER for exceptional customer service

STOBER is proud to help keep customers up and running by supplying exceptional customer service and the gold-standard in perfect motion.

STOBER featured in Business View Magazine

STOBER Drives, Inc. is featured in the September 2023 issue of Business View Magazine.

STOBER Hydraulic Motor Adapters mean more solutions

Most hydraulic motors have 2 or 4 bolt SAE flanges. We design

adapter plates and shaft hubs to mount the motors directly to our

gearboxes, making it as easy as possible for you.

STOBER culture topic of presentation for business leaders

Peter Feil, VP/General Manager, and Stephanie Gastauer, Talent Development Leader, recently presented information about the culture of STOBER Drives, Inc. to regional business leaders who gathered at Aileron in Tripp City, Ohio.

STOBER and Rockwell Automation’s partner network

STOBER partners with Rockwell Automation to deliver mechatronics solutions that enable our mutual end-customers to optimize their machine’s efficiency, create reliable solutions, and save space while being backed by an industry-leading warranty.

STOBER featured at General Mills conference

STOBER regional managers Brian Gerzsenyi, Nick Smith, and Mark Sticklen recently presented at the General Mills Maintenance & Reliability Leadership Conference. Their presentation focused on how to eliminate downtime related to gearboxes.

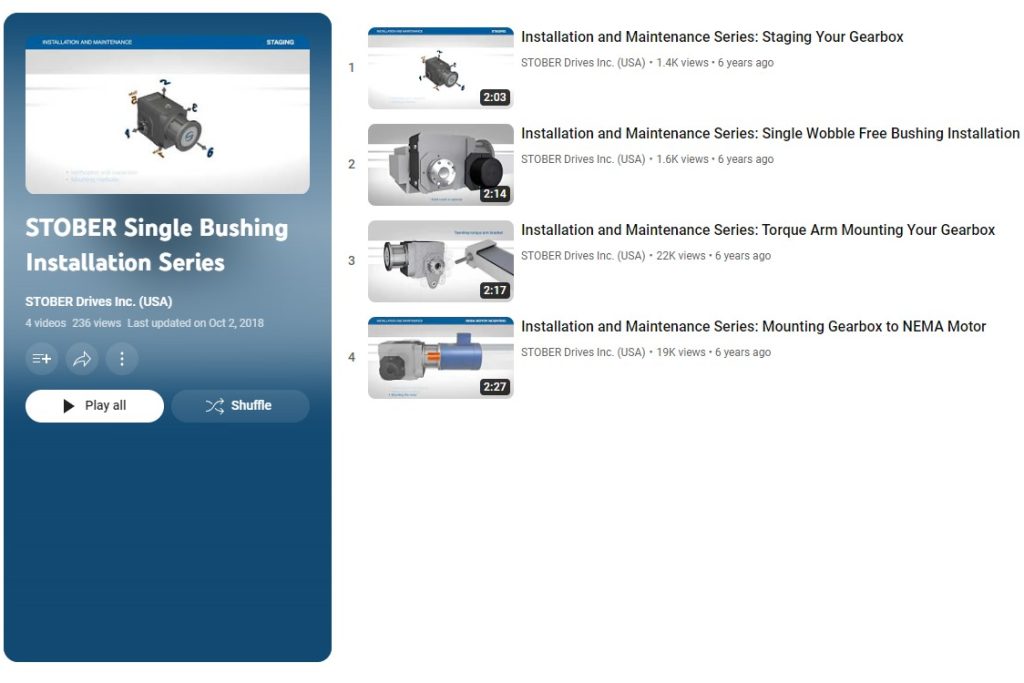

STOBER YouTube channel features valuable resources

If you’re unsure about how to install or perform maintenance on your STOBER gearbox and aren’t interested in reading a user’s manual to find what you need, look no further than a quick YouTube tutorial!

Selecting the best power transmission gearbox

With a variety of gearboxes on the market that can fulfill diverse requirements, selecting the best power transmission gearbox can be a challenge. Avoid making a wrong decision to avoid wasting money on a more expensive gearbox that isn’t necessary.

STOBER 3D modeling brings new perspective

As a consumer, you use 3D modeling when you research items such as cars, clothing, shoes, and appliances online, so why shouldn’t you see 3D models of your gearboxes too? Now you can with STOBER’s new 3D modeling tools.

Virtual customer meetings help STOBER increase efficiency

If you have questions about our products you’d like answered, a tough application you need a solution for, or just want to touch base and put a name with a face, us our Meeting Request tool to schedule some one-on-one time with our team!

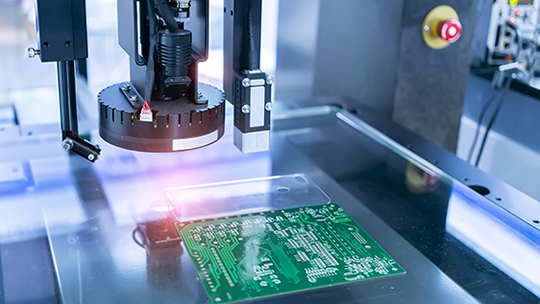

STOBER can improve machine reliability

Learn how STOBER can help improve your machine reliability and combat other common struggles for the semiconductor industry.

STOBER Oktoberfest Stein Dash Aug. 12

Join us at Maysville Oktoberfest on Saturday, Aug. 12 from 4 p.m. to 6 p.m. and find out at the STOBER Stein Dash!

STOBER can build & ship in one day from Maysville, Ky.

At STOBER, we’re proud to build and ship in only one day from our facility in Maysville, Kentucky, so our customers don’t have to worry about lead times.

Happy Retirement, Doug Reeves!

Doug Reeves, service team leader, has enjoyed working at STOBER for the past four years and is retiring July 21.

STOBER lunch benefit a success

Our HR team prepared sack lunches last week and raised more than $800 to benefit Christy Wilson Kirk, daughter of Bill & Cheryl. Cheryl’s Cleaning Service takes care of our custodial needs.

Geared motors for washdown applications

STOBER’s synchronous Servo geared motors are available in food duty or corrosion resistant options to meet washdown requirements.