We’re excited to announce that STOBER is hosting Open Interviews, and you’re invited!

We’re excited to announce that STOBER is hosting Open Interviews, and you’re invited!

Reduce storeroom inventory costs and boost efficiency with STOBER’s modular gearboxes and motors. Fewer SKUs, faster delivery, smarter design.

Discover how a leading food processor improved uptime, cut maintenance costs, and reduced energy use by 66% with STOBER’s cLEAN System—featuring washdown-ready gearboxes and motors.

While both keyed and keyless connections serve the same purpose of transmitting torque, they operate in fundamentally different ways. Understanding the distinctions between the two connection types can help you choose the best option for your systems.

Created to provide a long-lasting system that improves your plant’s reliability, STOBER’s cLEAN System is durable, efficient, and guaranteed to work in the harshest environments–it’s the world’s toughest system.

The new STOBER cLEAN System is hygienically designed, making it the ultimate solution for food processing.

The STOBER cLEAN System was named “Best of the Best” recipient at the 2025 International Production & Processing Expo (IPPE).

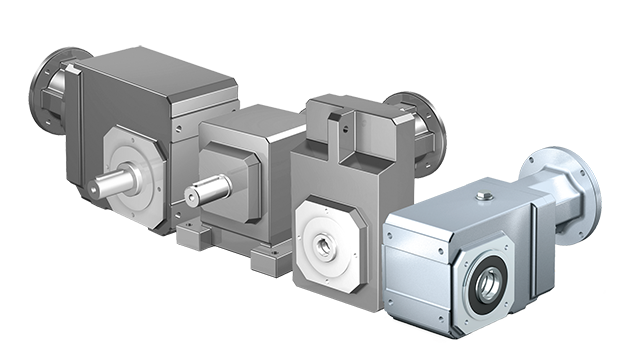

Did you know that the world’s toughest gearbox doesn’t require oil changes? STOBER’s KSS stainless steel, K, C, and F series reducers (in food-duty or corrosion-resistant options) require no maintenance due to efficient gearing, housing design, quality components, and expert assembly.

STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

Designed to provide the highest degree of resiliency and durability, STOBER’s NEMA gearboxes deliver superior performance that can revolutionize how well equipment functions across numerous processes and industries.