Reduce storeroom inventory costs and boost efficiency with STOBER’s modular gearboxes and motors. Fewer SKUs, faster delivery, smarter design.

Reduce storeroom inventory costs and boost efficiency with STOBER’s modular gearboxes and motors. Fewer SKUs, faster delivery, smarter design.

Discover how a leading food processor improved uptime, cut maintenance costs, and reduced energy use by 66% with STOBER’s cLEAN System—featuring washdown-ready gearboxes and motors.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

STOBER Drives, Inc. was honored to accept the Big Ass Fans Supplier of the Year award for 2024.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

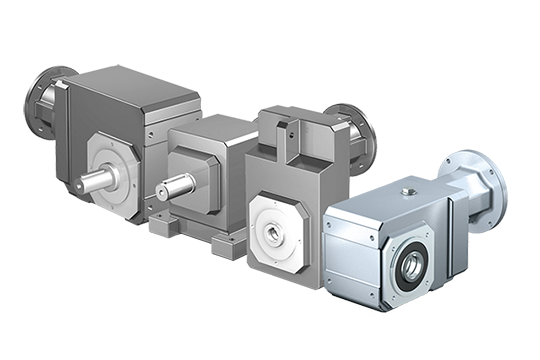

Optimize performance with STOBER’s precision gear units. We offer expert installation, maintenance, and 24/7 repair services to minimize downtime.

Prevent costly breakdowns and extensive industrial gearbox repair by learning eight warning signs that indicate repair is needed.