Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

Shelley Duncan, a utility employee on the STOBER assembly team, has worked at STOBER for about three years and will be retiring on May 31.

STOBER Drives, Inc. was honored to accept the Big Ass Fans Supplier of the Year award for 2024.

Discover how servo motors work. Learn about their precise control, high torque, and versatility in robotics and automation applications.

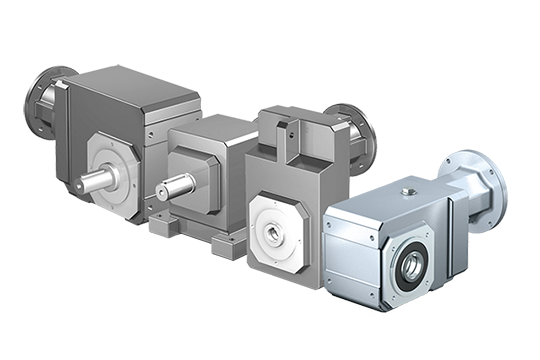

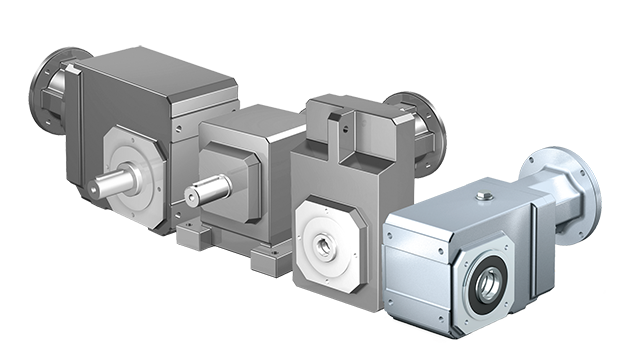

Optimize performance with STOBER’s precision gear units. We offer expert installation, maintenance, and 24/7 repair services to minimize downtime.

Prevent costly breakdowns and extensive industrial gearbox repair by learning eight warning signs that indicate repair is needed.

Designed to provide the highest degree of resiliency and durability, STOBER’s NEMA gearboxes deliver superior performance that can revolutionize how well equipment functions across numerous processes and industries.

While rack and pinion products are not new for STOBER, the new ZS Rack elevates STOBER’s rack and pinion offerings.

Commissioning a STOBER geared motor with a Bosch drive is easier than you may think. Watch the video for step-by-step instructions.