Many plants have $1 million of products in the storeroom, plus the cost of time and space to stock, maintain, and manage it. STOBER can help reduce the need for expensive storerooms.

Many plants have $1 million of products in the storeroom, plus the cost of time and space to stock, maintain, and manage it. STOBER can help reduce the need for expensive storerooms.

Prevent premature gearbox failure with one simple trick—eliminating water or chemical ingress in your gearbox! Read more to learn how.

Accuracy, stiffness, and life are all important in machine tool design. STOBER has the knowledge and products to successfully accomplish all three.

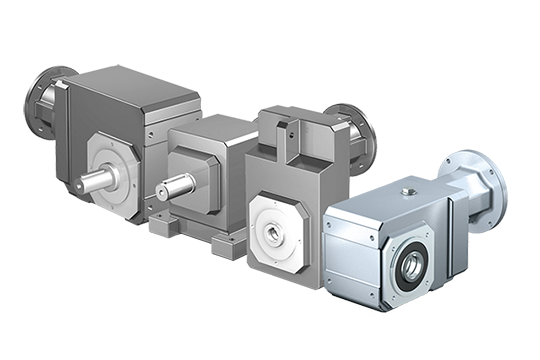

Geared motors can improve machine design while saving money. By eliminating extra components, such as the motor coupling, the solution is lighter and more compact. Plus, wear components are reduced, which equals less maintenance. There are many other benefits to a geared motor—read more about the top five below.

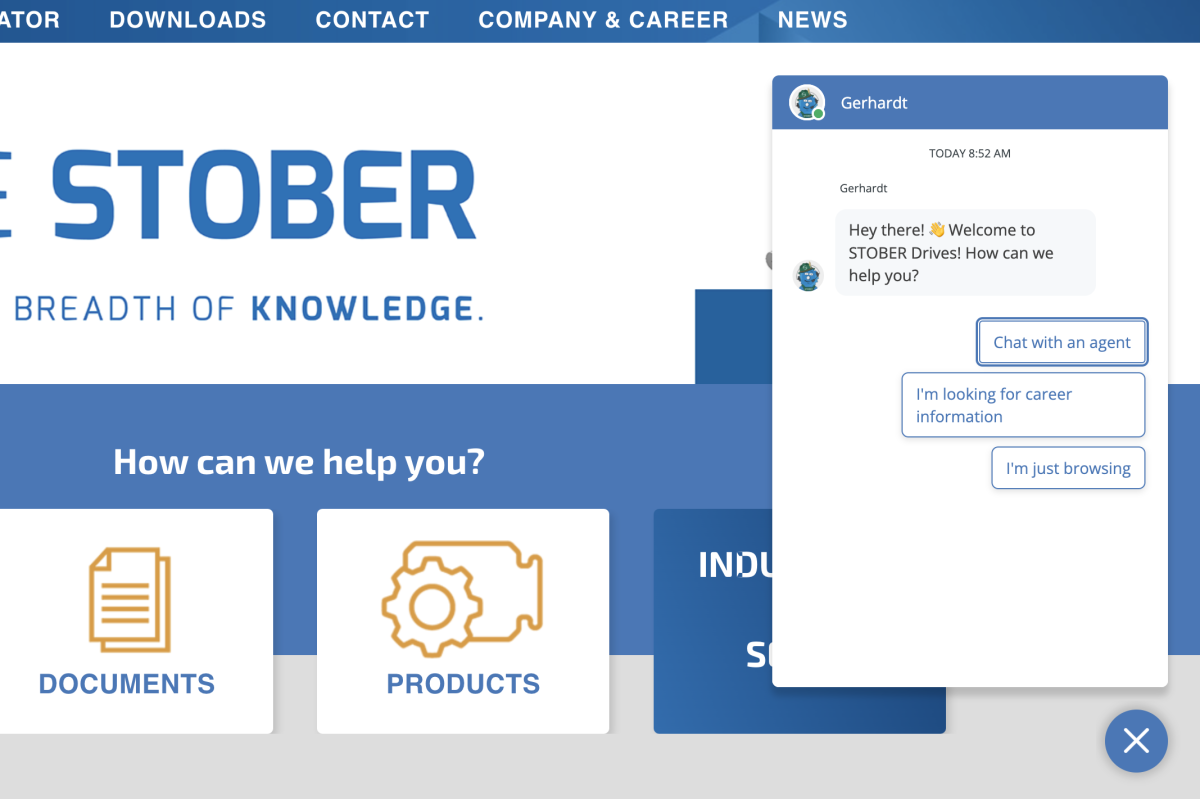

Chat with an engineer for help with part numbers, troubleshooting, identifying solutions for your application, and more.

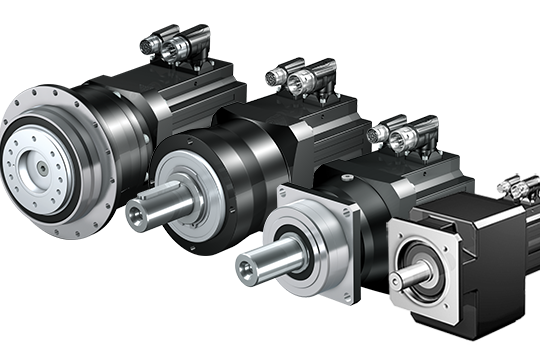

STOBER motors and geared motors are used in many different applications where the customer has implemented the communication protocol of their choice upstream in their application. Contact us today to see how we can help you find the optimal solution for your application.

est Places to Work in Kentucky for the fifth straight year, earning a spot in the Hall of Fame.

STOBER values responsibility. But what does that mean? Check out our blog to read about one employee’s explanation.

STOBER geared motors and motors are Hiperface DSL compatible, but how does it work and what are the advantages? Read more.

Continual improvement in the workplace, products, and solutions gives STOBER an advantage over the competition.