STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

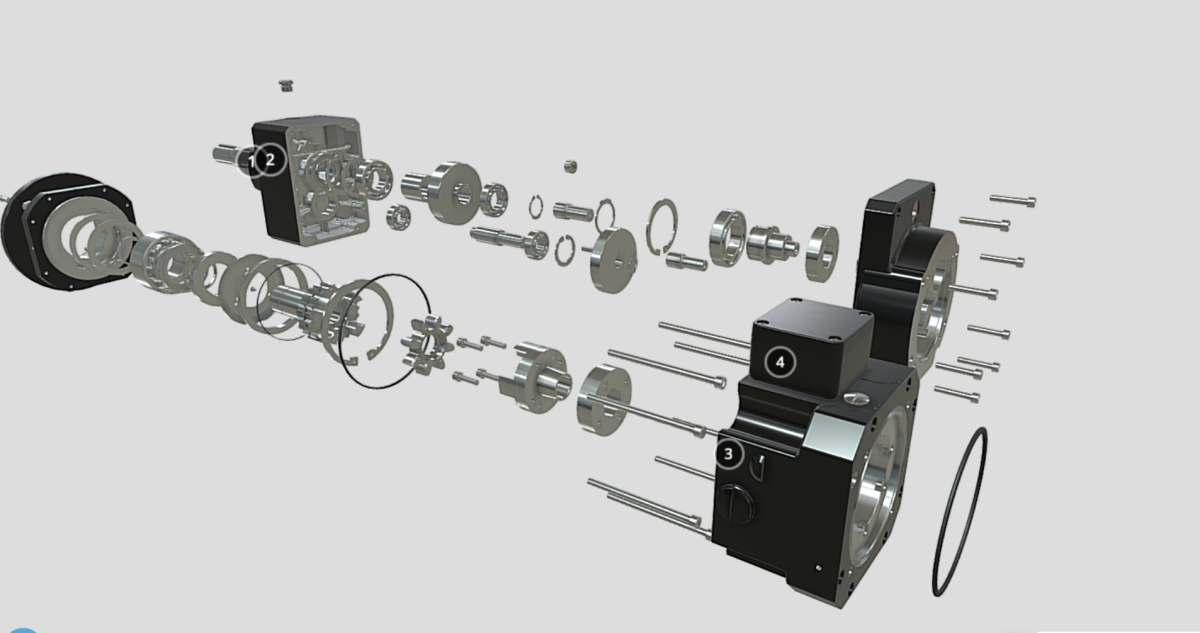

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gearboxes, you’re in luck—3D models of the product are now available on the STOBER website!

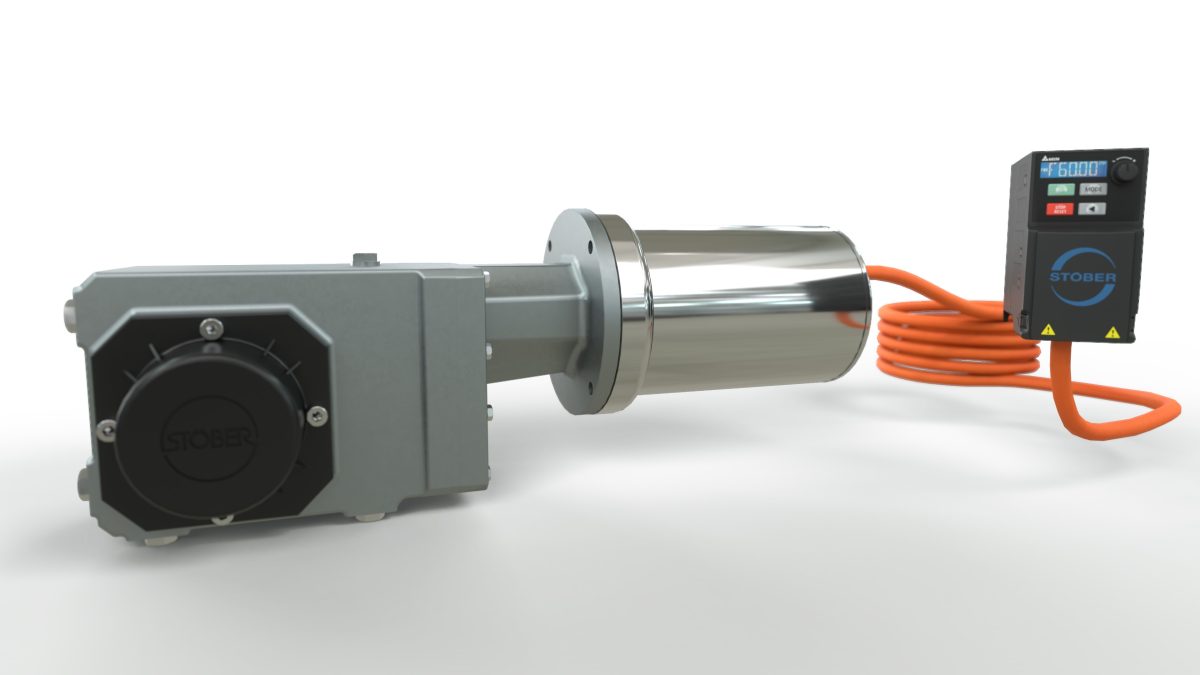

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

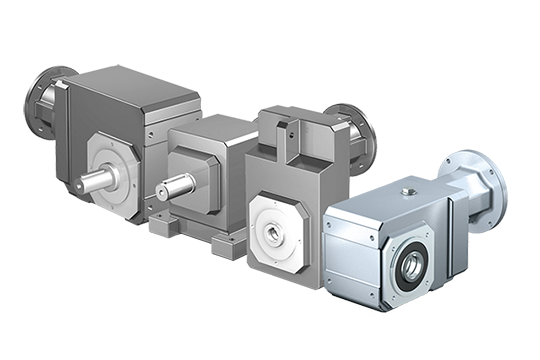

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

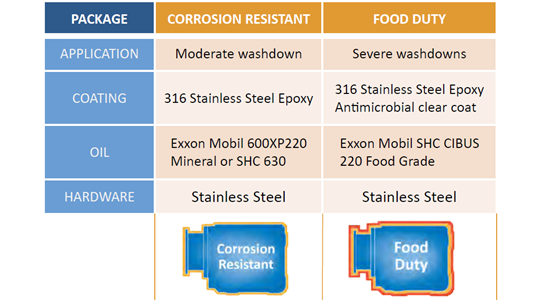

STOBER washdown geared motors deliver corrosion resistance, hygienic design & superior durability for food, beverage & industrial washdown environments.

Gearbox oil guide covering the top 5 factors in oil selection. Discover how viscosity, additives & testing affect gearbox efficiency, durability & cost.

Water ingress prevention starts with sealed, IP69K-rated gearboxes. Learn how to protect industrial drives from moisture, corrosion & washdown damage.