“How much do gearboxes cost?” rarely has a simple answer. Depending on the gearbox type, materials, and performance demands, prices can range from a few hundred dollars to well over ten thousand. On average, gearbox prices fall into three tiers:

- Light-duty gearboxes used in conveyors or small packaging equipment typically range from $300 to $800.

- Medium-duty units for agricultural, food-processing, or robotics applications often cost $800 to $2,500.

- Heavy-duty gearboxes—for mining, marine, or defense operations—commonly start around $3,000 and can exceed $10,000 depending on torque and environmental protection requirements.

This wide variation exists because every gearbox must meet specific torque, load, and duty-cycle needs. A manual gearbox used in basic automation tasks costs less than a servo-integrated or planetary model designed for high-precision motion control. A gearbox built for continuous operation in a washdown-rated environment, for example, costs more due to stainless-steel housings and NSF-certified seals. Units with tighter backlash tolerances or high-precision planetary gearing command premium pricing because they require advanced machining and assembly standards.

When weighing gearbox prices, it’s also important to note that customization, modular configurations, and compliance certifications all influence cost. Food-grade gearboxes, explosion-proof housings, or cleanroom designs all require special materials and additional validation testing. For many buyers, the final gearbox cost estimation reflects both the application’s rigor and the long-term reliability demanded by their industry.

If you’re unsure which design best fits your needs, STOBER’s guide to selecting the perfect servo gearbox explains how configuration, torque, and mounting style affect your total investment.

Key factors that influence gearbox cost

Each gearbox price tag reflects a robust combination of engineering, material, and operational decisions. Understanding these factors helps explain why two similar-sized gearboxes might differ in cost by thousands of dollars.

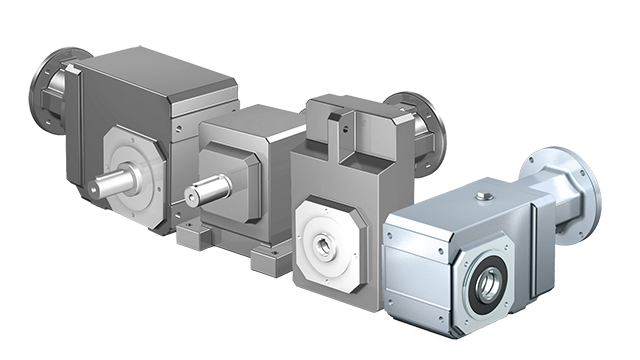

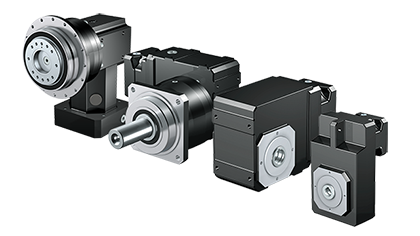

Design complexity is often the first cost driver. A single-stage helical gearbox is simpler and cheaper to produce than a multi-stage planetary gearbox that must deliver precise motion and high torque density. Multi-stage systems require tighter tolerances and specialized assembly.

Material composition matters, too. Standard cast-iron housings are economical and durable, but stainless-steel or aluminum housings used in corrosive or hygienic environments increase production cost. Surface coatings—such as nickel plating or epoxy paint—add protection but also raise the price.

Performance specifications such as torque, shock-load rating, and continuous-duty capability directly influence component sizing. Bearings, seals, and heat-treated gears built for 24/7 industrial workloads cost more but last longer, lowering lifetime expenses. Certifications and compliance—ATEX for hazardous environments, ISO for quality, or NSF for food-grade safety—require additional testing and documentation that contribute to the overall industrial gearbox cost breakdown.

Finally, production scale and urgency play powerful parts in the process. Custom one-off builds lack the economies of scale found in high-volume production, while expedited orders or overnight replacements typically carry premium surcharges.

For buyers comparing multiple gearbox suppliers, these factors explain why price alone is rarely the best indicator of value. Modular gearbox pricing can outperform cheaper units and save thousands in unplanned downtime over its lifespan.

When to repair, rebuild, or replace a gearbox

Even the best gearboxes eventually wear. Deciding between a gearbox repair, gearbox rebuild, or gearbox replacement can significantly impact both cost and uptime.

A repair addresses isolated faults such as worn seals, bearings, or gears. It’s the least expensive option—usually $500 to $5,000, depending on the issue and brand—but may not resolve underlying wear if the housing or shafts are degraded.

A rebuild goes a step further: technicians disassemble the gearbox, inspect all components, replace key parts, and reassemble to OEM standards. Rebuilds generally cost $1,500 to $4,000, offering a practical balance between expense and long-term reliability.

A replacement introduces an entirely new unit, which is ideal when the damage is severe, the model is obsolete, or performance needs have changed. New gearboxes typically cost $2,000 to $10,000 or more.

When comparing gearbox repair costs, consider total cost of ownership rather than immediate savings. If the cost to rebuild exceeds 60 percent of a new unit, or if repeated gearbox issues disrupt production, replacement often delivers better ROI. Our guide on signs it’s time to replace your gearbox outlines key indicators to guide this decision.

Facilities with access to professional gearbox repair and service can extend lifespan and reduce unplanned downtime through proactive maintenance programs. Many industrial users find that rebuilding a reliable housing multiple times is still more cost-effective than purchasing lower-quality replacements.

Ignoring recurring gearbox problems or allowing a faulty gearbox to remain in operation increases the cost of gearbox failure, which includes lost production, emergency repairs, and potential safety risks. Severe gearbox damage can require full unit replacement plus system recalibration, driving costs much higher.

Tips to control gearbox costs over time

Managing gearbox maintenance costs is the most effective way to reduce lifetime spending. Preventive care helps avoid catastrophic failures that require full replacement.

- Perform regular oil changes and lubricant analysis. Tracking viscosity and contamination can reveal early wear.

- Monitor vibration and temperature trends. These parameters indicate bearing fatigue or misalignment long before visible damage occurs.

- Ensure proper alignment between the motor and gearbox. Misalignment causes side loading, seal wear, and premature bearing failure.

- Inspect seals and fasteners routinely. Early intervention prevents leaks that could damage internal gears.

- Train operators on load limits, soft starts, and proper shutdown sequences to prevent unnecessary stress on components.

A well-maintained gearbox can operate for 20 to 30 years, drastically reducing total cost of ownership. While preventive care requires some investment, it’s still minor compared to production losses from an unexpected gearbox failure.

Choosing a supplier that supports installation, maintenance andaftermarket support ensures consistent performance and easy access to OEM-grade parts. STOBER gearboxes are designed to be the least expensive gearbox you’ll ever own thanks to long service intervals, modular design, and sealed-for-life options.

For engineers seeking flexibility, modular configurations like STOBER’s modular customization allow targeted upgrades without full replacement, lowering capital expense across the asset’s lifecycle. STOBER’s servo gearboxes andmotors showcase how precision, efficiency, and adaptability come together to minimize total ownership costs.

Gearbox pricing is about more than just the sticker price

Ultimately, gearbox cost comparison comes down to value over time, not just the initial purchase. The cheapest option can become the most expensive if it fails prematurely or causes production downtime.

A gearbox’s price reflects its engineering, material quality, and the reliability it delivers throughout its life. Partnering with experienced gearbox suppliers like STOBER means access to engineering consultation, custom configurations, and long-term parts availability—all factors that reduce lifetime cost and risk.

Whether you’re designing a new system or upgrading an existing one, focus on total lifecycle performance. STOBER’s innovative designs, from helical bevel to cost-effective gearbox solutions, demonstrate how efficiency, durability, and support combine to make each purchase a strategic investment in uptime, safety, and profitability.

Try the STOBER Configurator or get in touch with our team for personalized recommendations. To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

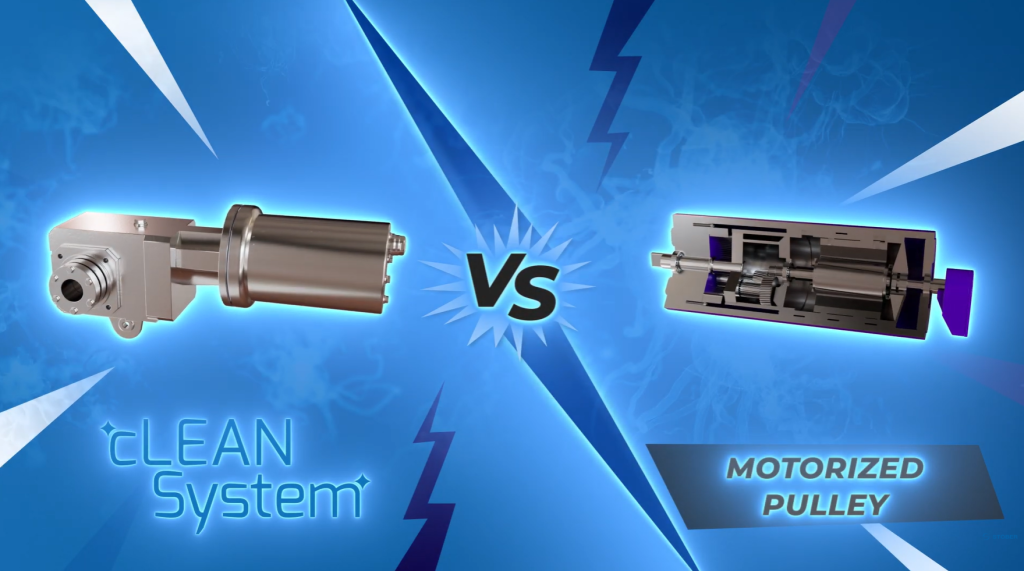

STOBER cLEAN System outperforms motorized pulley in food processing environments

STOBER cLEAN System outperforms motorized pulley in food processing environments  Ideal gearbox selection: Practical sizing checklist to save money

Ideal gearbox selection: Practical sizing checklist to save money  STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

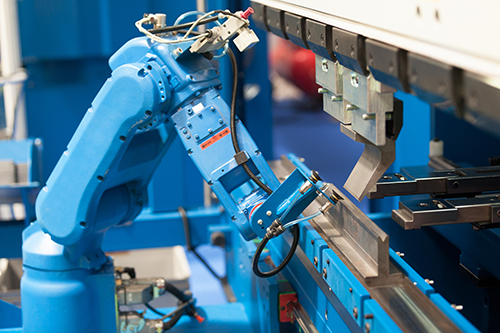

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

Selecting gearboxes for robotic & industrial automation systems