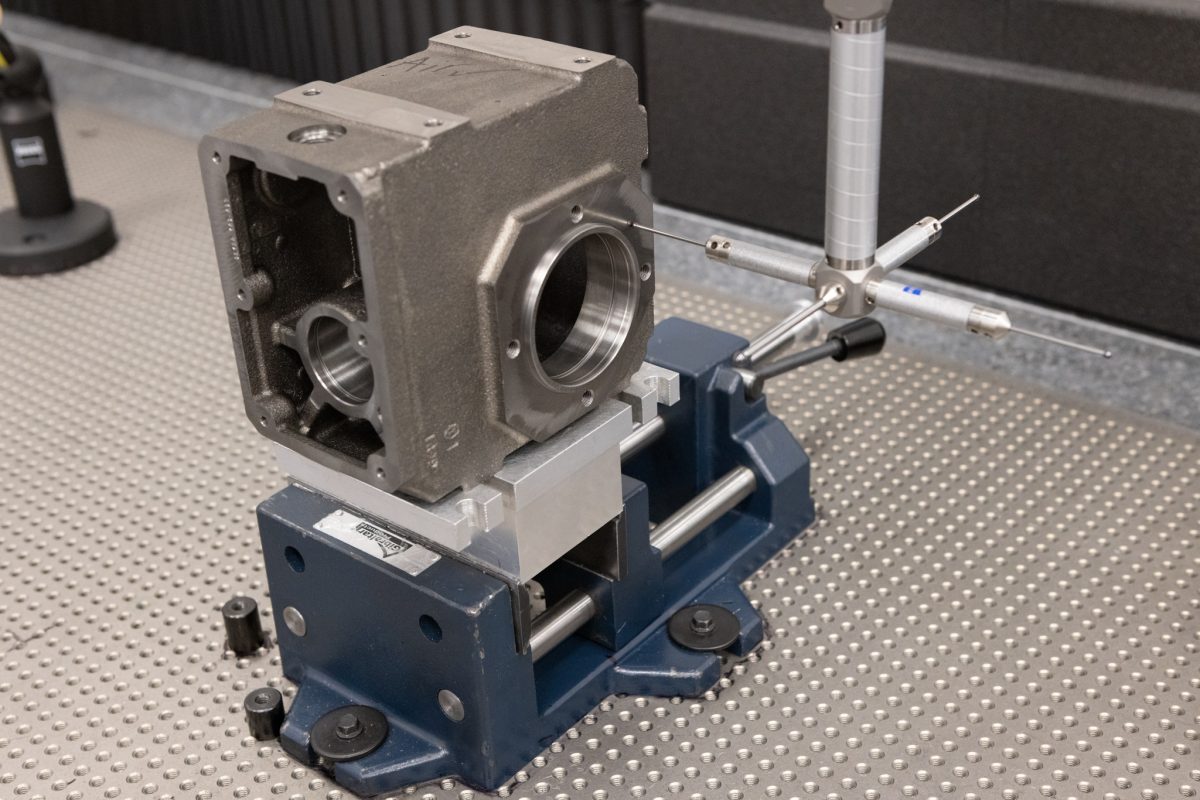

Ideal gearbox selection starts with load data, service factors & environment. Use this sizing checklist to avoid oversizing, cut costs & extend gearbox life.

Ideal gearbox selection starts with load data, service factors & environment. Use this sizing checklist to avoid oversizing, cut costs & extend gearbox life.

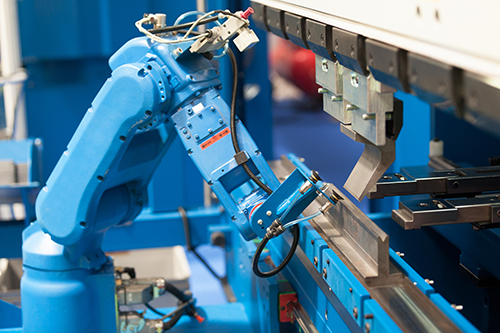

Learn how to choose gearboxes for automation & robotics—planetary, helical, or helical-bevel—based on load, precision, environment & lifecycle cost.

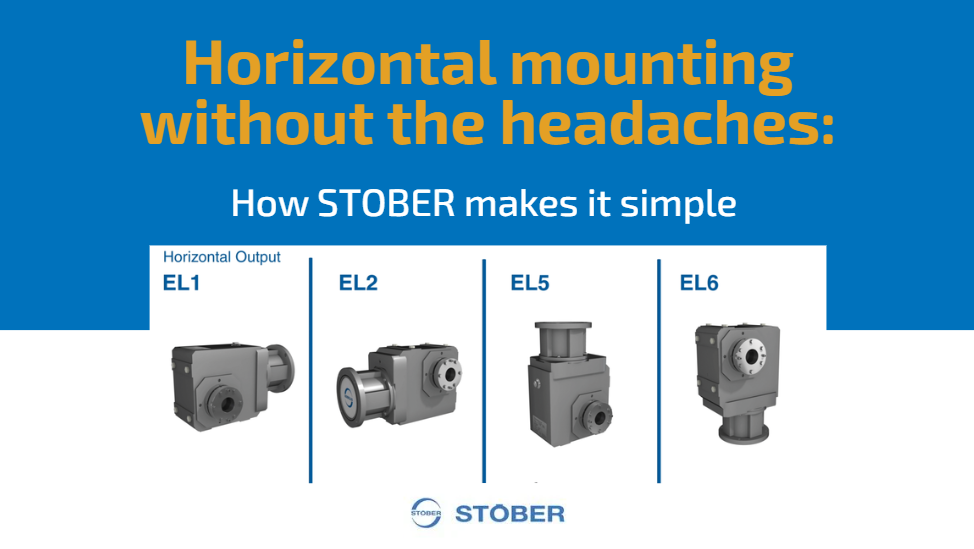

Discover how STOBER eliminates the complexity of horizontal gearbox mounting with flexible, any‑orientation installation, reliable lubrication design, and leak‑proof seals—saving teams time, effort, and costly mistakes.

Learn what causes failure in industrial gearboxes—lubrication breakdown, misalignment, overload, contamination & wear—plus warning signs to catch early.

Reduce gearbox noise by fixing root causes like gear mesh issues, poor lubrication, misalignment, and vibration so drives run smoother, quieter, and longer.

Looking for details on an old STOBER unit or inventory item? Use the STOBER Product ID Tool to instantly access installation guides, technical specs, and parts lists.

Discover how STOBER delivered a “Christmas Miracle” with fast gearbox support, building a lasting partnership and driving OEM success.

Learn best practices for industrial gearbox maintenance to reduce downtime, boost efficiency & extend equipment life with proper inspection and lubrication.

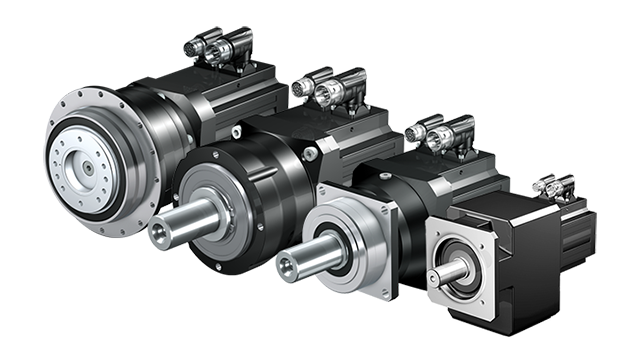

Meet some of the minds behind STOBER! Our engineers who design our precision gearboxes, servo geared motors, and motion control solutions—sharing the ideas, culture, and craftsmanship that power industrial automation.

Explore the main types of geared motors, including planetary, helical, worm & right-angle designs, and learn how each supports precision, torque, & efficiency.