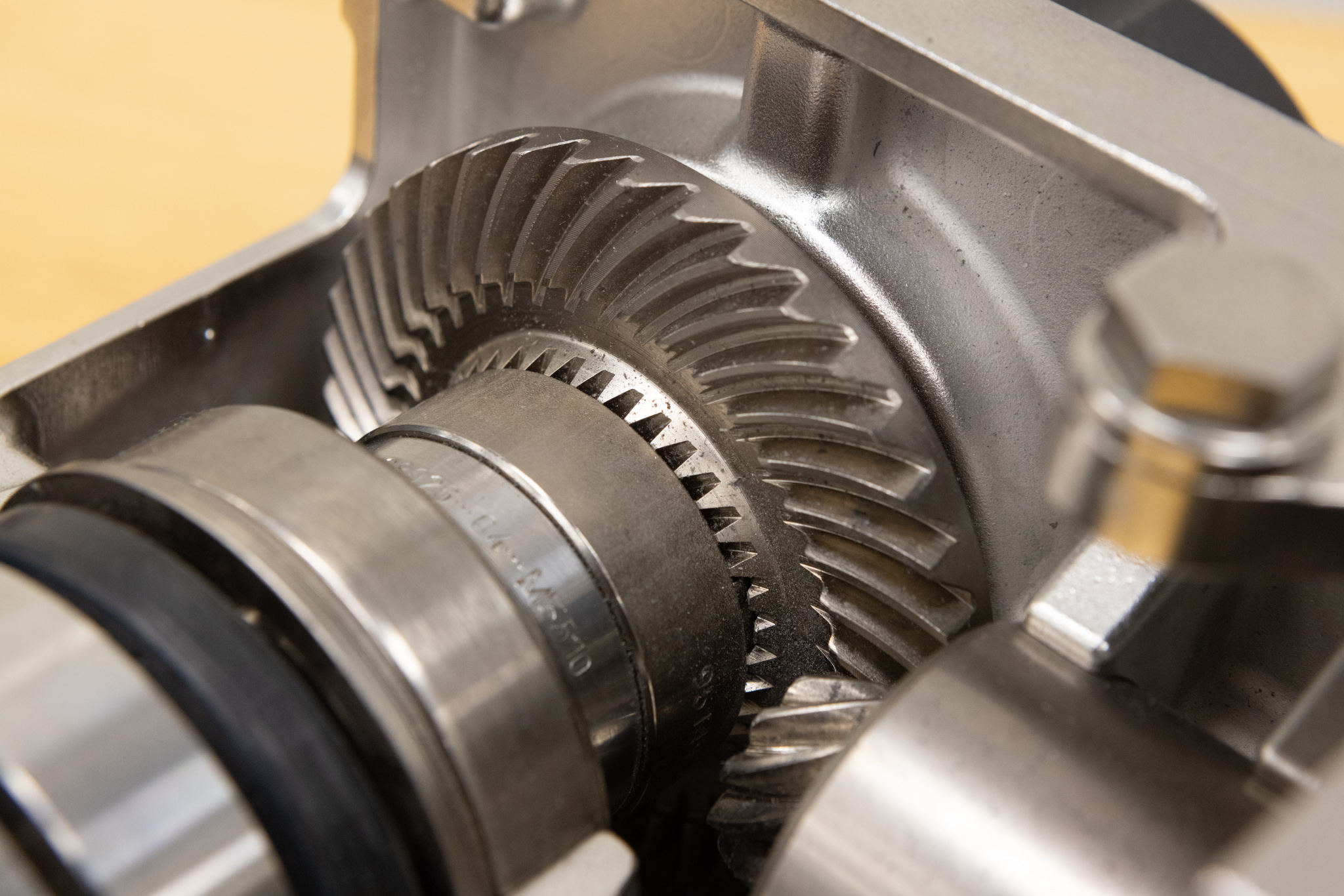

Horsepower, torque ratings, and efficiency percentages often come to mind when thinking about a gearbox. But behind every smooth-running gearbox is something a little less obvious, but equally critical–geometry of the gear teeth. Tooth shape and design directly influence load capacity, noise, efficiency, and service life. Studying the science behind gear tooth geometry helps us understand why some gearboxes perform flawlessly for decades while others wear out prematurely.

Why gear tooth geometry matters

Every gear tooth is designed to transfer torque smoothly while minimizing friction, vibration, and wear. The geometry, or the shape and alignment of the teeth, determines how efficiently this transfer occurs. Small, subtle differences in the profile of a gear tooth can significantly affect:

- Durability – Correct geometry prevents localized stress that can cause pitting, cracking, or early failure

- Load distribution – Well-designed geometry spreads forces evenly across the tooth face, reducing stress concentrations

- Efficiency – Smooth rolling contact reduces friction losses and wasted energy

- Noise and vibration – Poorly designed or misaligned teeth lead to chatter, noise, and premature wear

Key elements of gear tooth geometry

1. Involute profile

Most modern gears use an involute curve for the tooth shape. This geometry ensures that as gears rotate, the contact point between teeth moves smoothly, maintaining a constant velocity ratio. Without this, torque transfer would be uneven, leading to vibration and inefficiency.

2. Pressure angle

The pressure angle, the angle at which force is transmitted between teeth, affects load capacity and strength. Common angles include 14.5°, 20°, and 25°. Higher angles typically allow stronger teeth but increase radial forces, which can stress bearings.

3. Helix angle (for helical gears)

Helical gears introduce a helix angle that spreads the load across multiple teeth at once. This reduces noise and increases capacity, but also introduces axial forces that must be managed with bearings.

4. Face width

A wider face allows more surface contact, which improves load distribution and increases torque capacity. However, excessive width can lead to misalignment issues if not supported properly.

5. Backlash

A small amount of clearance between teeth is necessary to allow lubrication and account for thermal expansion. Too much backlash reduces precision, while too little can cause binding.

How geometry impacts real-world performance

Design choices made in gear tooth geometry affect how a gearbox performs in demanding environments:

- High-precision applications like robotics or CNC machines require tight tolerances, optimized backlash, and carefully calculated helix angles to minimize vibration.

- Heavy-duty industries such as mining or bulk material handling rely on robust tooth geometry that can withstand shock loads and abrasive conditions.

- Food and pharmaceutical processing often demand gearboxes with optimized profiles that reduce friction, minimize heat, and perform reliably in washdown conditions.

Ultimately, gear tooth design is a balancing act—choosing the right geometry for the application ensures maximum performance, efficiency, and longevity.

The STOBER advantage

At STOBER, gear tooth geometry isn’t just theory—it’s thoughtfully built into every product. Our engineers design gears with optimized profiles, helix angles, and load distribution to deliver efficiency and precision that far exceeds industry standards.

- High-performance helical gears – STOBER’s inline helical gearboxes use hardened, precision-ground helical gears that run smoother, quieter, and more efficiently. The inline helical gearboxes can be mounted to any motor with our toleranced motor adapters, or you can add a STOBER motor to them to make a geared motor.

- Tight tolerances – At STOBER, every gearbox is manufactured to the gold standard, ensuring minimal backlash, optimal precision, and maximum reliability.

- Application-specific solutions – Whether you need extreme precision for automation or durability for harsh environments, STOBER has a gearbox engineered with the right tooth geometry for the job.

By combining advanced gear design with decades of engineering expertise, STOBER gearboxes deliver longer service life, reduced maintenance, and unmatched efficiency.

Final thoughts

The science of gear tooth design is complex, but its impact is simple – better geometry equals better performance. From the smallest servo gearbox to heavy-duty industrial drives, the shape and precision of every gear tooth determine how well your system runs.

When performance, reliability, and efficiency matter most, you need more than just a gearbox—you need a gearbox designed with precision at the tooth level and beyond. That’s the STOBER difference.

Ready to find the right gearbox for your application? Contact our team to discuss your needs and explore STOBER’s solutions at (888) 786-2371 or email sales@stober.com. Still researching? Use the link below to view our Power Tips to learn more about the top three beefits of helical gearboxes.

Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025  The Christmas miracle: How STOBER delivered when it mattered most

The Christmas miracle: How STOBER delivered when it mattered most