Knowing how to calculate gear reduction is a must for engineers and technicians designing reliable power transmission systems. Whether you’re developing an industrial gearbox, a robotic arm, or a conveyor drive, proper gear reduction provides the right balance of torque and speed while maintaining gearbox efficiency.

Throughout this guide, we break down the whole process — from basic principles to advanced calculations and real-world gear reduction examples — to help you achieve optimal performance in any mechanical system.

Introduction to gear reduction

In mechanical systems, gear reduction refers to the process of decreasing input speed while increasing output torque through the interaction of meshed gears. This makes it a fundamental principle in everything from packaging machinery to automotive powertrains.

While the term “gear reduction” is often used interchangeably with “gear ratio,” the two are related but distinct. The gear ratio quantifies the relationship between two gears; specifically, how many revolutions the input gear makes compared to the output gear. A reduction occurs when the driven gear has more teeth than the driving gear, resulting in slower output rotation but higher torque.

Striking a balance between mechanical advantage and power transmission efficiency is what makes gear reduction so vital. For industrial gear reduction applications, such as in conveyors, robotics, or motion control systems, calculating precisely can prevent unplanned downtime and extend the lifespan of both the motor and gearbox.

Gear reduction formula explained

The most direct way to calculate gear reduction is through the gear ratio formula:

Gear ratio = (Number of teeth on driven gear) ÷ (Number of teeth on driving gear)

Here’s what each term means:

- Driving gear (input gear/pinion): the gear connected to the power source, such as an electric motor.

- Driven gear (output gear): the gear receiving motion and torque from the driving gear.

If the driven gear has more teeth, it turns slower than the driving gear, providing a torque increase.

For example, if a 10-tooth pinion drives a 50-tooth gear:

- Gear ratio = 50 ÷ 10 = 5:1

- This means the input gear rotates five times for every one rotation of the output gear. In practical terms, torque increases fivefold while speed decreases by the same factor. This simple gear ratio example illustrates how speed and torque scale within a reduction system.

Ratios greater than 1:1 indicate reduction, while ratios less than 1:1 represent overdrive conditions, where the output turns faster than the input. By having a solid grasp on how to calculate gear ratio, engineers can design systems that meet performance targets for rotational speed and torque balance.

Step-by-step process to calculate gear reduction

To calculate gear reduction in real-world systems, follow this proven process:

Step 1: Identify input and output gears

Determine which gear is connected to the power source (input) and which delivers the output motion. This dynamic defines your input to output gear ratio.

Step 2: Count the teeth

Record the number of teeth on both gears. If the tooth count is unavailable, you can substitute the pitch diameters.

Step 3: Apply the formula

Use the standard formula:

Gear Ratio = Driven Gear Teeth ÷ Driving Gear Teeth

Step 4: Analyze torque and speed changes

Output torque = Input torque × Gear ratio

Output speed = Input speed ÷ Gear ratio

Step 5: Validate system performance

Compare your results against the mechanical requirements to make sure that the torque output and speed align with design specifications.

Multi-stage gear reduction

In complex gear trains, multiply each stage’s ratio to find the total reduction.

Example: A 2:1 stage combined with a 3:1 stage produces a total ratio of 6:1.

It’s also important to account for losses from friction, backlash, and heat. Real-world gearboxes rarely achieve 100% power transmission efficiency — most range from 90% to 98%, depending on design and lubrication quality. Losses affect rotational speed and torque output, so engineers need to adjust their calculations accordingly.

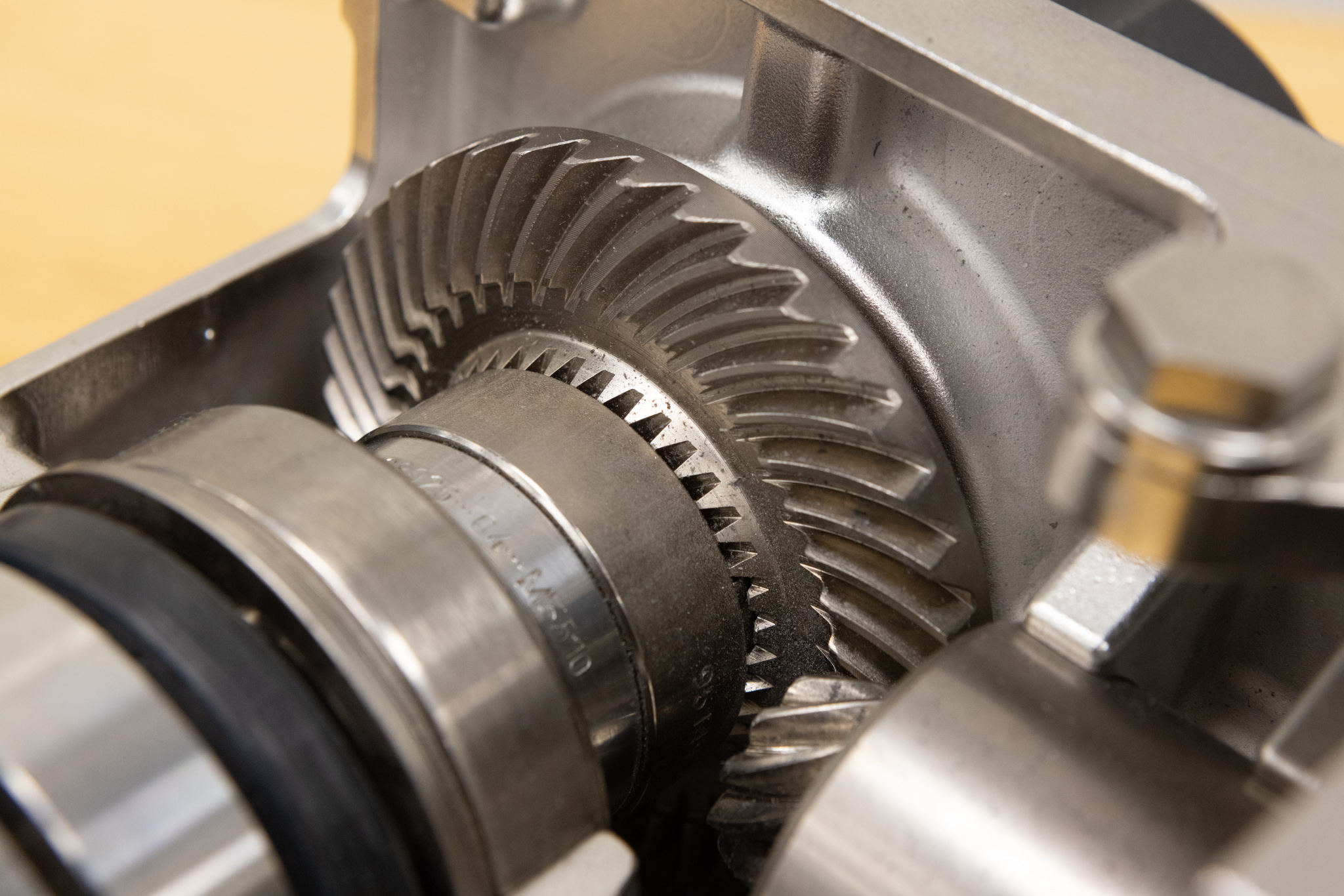

Common types of gear reduction systems

Different gear systems achieve reduction in different ways. The most common include:

- Spur gear reduction: Simple, cost-effective, and easy to calculate. Common in low- to medium-load applications where noise is not a primary concern.

- Helical gear reduction: Features angled teeth for smoother, quieter operation and higher load capacity. Ideal for continuous-duty systems that require high efficiency.

- Planetary gear reduction: Compact, precise, and capable of handling very high torque. Often used in robotics and automation for excellent torque density.

- Worm gear reduction: Offers extremely high ratios in compact designs, commonly used in lifts and conveyors. However, efficiency is lower due to sliding friction.

Designers select between parallel shaft and right-angle gearboxes based on space and layout constraints. Gear reduction design allows engineers to balance torque, efficiency, and mechanical footprint. STOBER’s precision gear reducers exemplify how configurations can deliver optimized performance and longevity for industrial and motion control systems.

Practical examples of gear reduction calculations

Example 1: Conveyor system

- A conveyor motor runs at 1,800 RPM and needs to turn a belt at 90 RPM.

- Required gear reduction = 1,800 ÷ 90 = 20:1.

- Using a 10-tooth input gear and a 200-tooth output gear would achieve the target speed.

- If efficiency losses are estimated at 5%, the system still maintains a practical torque increase suitable for load handling.

Example 2: Robotics application

- Precision robotic arms rely on multi-stage gear reduction for fine motion control.

- A total ratio of 100:1 allows slow, controlled arm movement with significant torque for lifting components without overshoot.

Example 3: Automotive transmission

- In a car’s gearbox, a 3.5:1 reduction in first gear multiplies engine torque for acceleration.

- As the driver shifts up, ratios approach 1:1 for speed rather than torque.

Across all examples, the principle remains the same: counting gear teeth and applying the formula ensures predictable, efficient power transfer. STOBER engineers use the same foundation when configuring servo gearboxes and motor-drive combinations, supported by tools like the STOBER configurator to streamline selection and design.

Factors affecting gear reduction efficiency

Even perfectly calculated ratios can underperform if the mechanical conditions aren’t ideal. Key efficiency factors include:

- Backlash: Excess clearance between gear teeth can reduce precision in motion control, especially in automation.

- Material selection: Steel provides durability and load strength; aluminum or composites reduce weight for lighter-duty applications. Choosing the right gear material selection directly affects wear resistance and longevity.

- Lubrication: Proper lubrication minimizes friction, heat, and wear. Inadequate lubrication can lead to rapid performance degradation.

- Load conditions: Shock or variable loads require stronger gears and precise alignment to prevent premature failure.

- Heat and alignment: Misalignment or overheating can lower gearbox efficiency and shorten component life.

Combining accurate calculations with sound design practices improves power transmission efficiency and can lead to substantial cost savings across industrial systems.

Why accurate gear reduction calculation matters

Accurate gear reduction calculations directly influence mechanical performance, energy efficiency, and equipment lifespan. When reduction is miscalculated, systems may suffer from insufficient torque, excessive heat, or unexpected downtime. In contrast, well-calculated ratios support stable operation and prolonged service life — especially in industrial automation, packaging, and robotics.

STOBER’s precision-engineered products help engineers achieve these outcomes through durable, efficient designs and expert technical support. From configuring compact planetary drives to high-efficiency parallel shaft systems, STOBER provides the expertise and resources to help you optimize performance from the start.

Try the STOBER Configurator or get in touch with our team for personalized recommendations. To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025