At STOBER Drives, innovation isn’t just a buzzword—it’s a commitment. Last month, our paint department and maintenance team demonstrated that commitment by working tirelessly to install and commission a major upgrade to our paint proportioning system. The result? A leap forward in precision, efficiency, and operator experience.

Introducing the EcoDose System

The centerpiece of the upgrade is the EcoDose proportioning system, which mixes paint on the fly with remarkable accuracy—dosing color and hardener components within ±1% using Coriolis meters. This ensures consistent, high-quality finishes every time.

EcoDose doesn’t just mix, it monitors pot life and automatically flushes paint lines with deionized water if time runs out, preventing hardening and reducing waste. Operators now control the system through a remote panel with pneumatic push buttons, selecting paint recipes, loading the gun, and purging lines with ease. The remote HMI provides real-time data on pot life, system status, flow rate, and temperature.

Speed & simplicity

Paint booth 2 now operates independently with its own pumps and pail lifts. These lifts streamline bucket changeovers and minimize mess, while Dürr 3:1 pumps add filtration, fluid regulation, and recirculation capabilities, returning unused paint to the bucket for maximum efficiency.

Color changes that once took several minutes now happen in under two. That’s not just faster—it’s smarter.

Ergonomics & automation with EcoGun 249

The new EcoGun 249 is a game-changer for our painters. Lighter and more ergonomic, it replaces the old siphon-based system with a flush box that handles color changes, purging, and loading automatically. If pot life expires, the system cleans the lines without manual intervention—keeping operations smooth and stress-free.

This upgrade reflects our ongoing dedication to quality, safety, and continuous improvement. Huge thanks to the Paint team and everyone who made this transformation possible. Your hard work is painting a brighter future—one coat at a time.

Learn more about STOBER’s paint process at the button below and contact us today and we’ll help you configure your next solution.

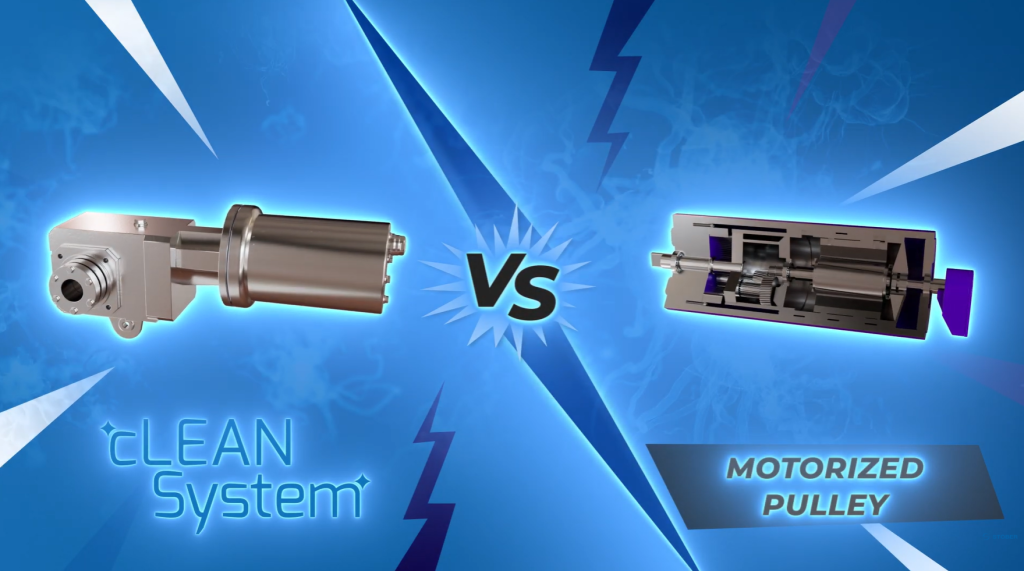

STOBER cLEAN System outperforms motorized pulley in food processing environments

STOBER cLEAN System outperforms motorized pulley in food processing environments  Ideal gearbox selection: Practical sizing checklist to save money

Ideal gearbox selection: Practical sizing checklist to save money  STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

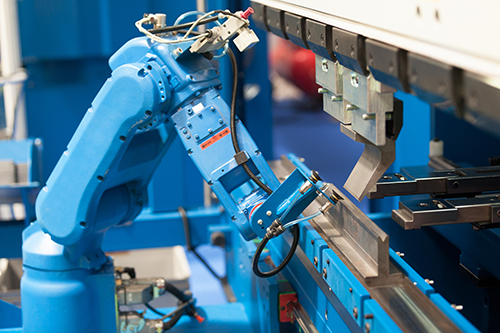

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

Selecting gearboxes for robotic & industrial automation systems