Industrial gearboxes are built to run for years, often quietly doing their job until something changes. Loads creep up. Lubrication degrades. Alignment drifts, or the environment takes a toll. Understanding what causes gearbox failure goes beyond one broken part, rather, it focuses on seeing how stresses build over time.

When you recognize gearbox failure causes early, you can address small issues before they snowball into a faulty gearbox and lost production or unexpected and unplanned downtime. Below is a practical look at why industrial gearbox failure happens and how to spot the warning signs before damage becomes irreversible.

What causes gearbox failure? A practical framework of failure modes

In industrial settings, gearbox failure doesn’t always mean a dramatic breakdown. It usually starts as a subtle loss of performance that escalates if ignored. At its core, failure means the gearbox can no longer transmit torque or speed reliably without excessive heat, noise, vibration, or wear.

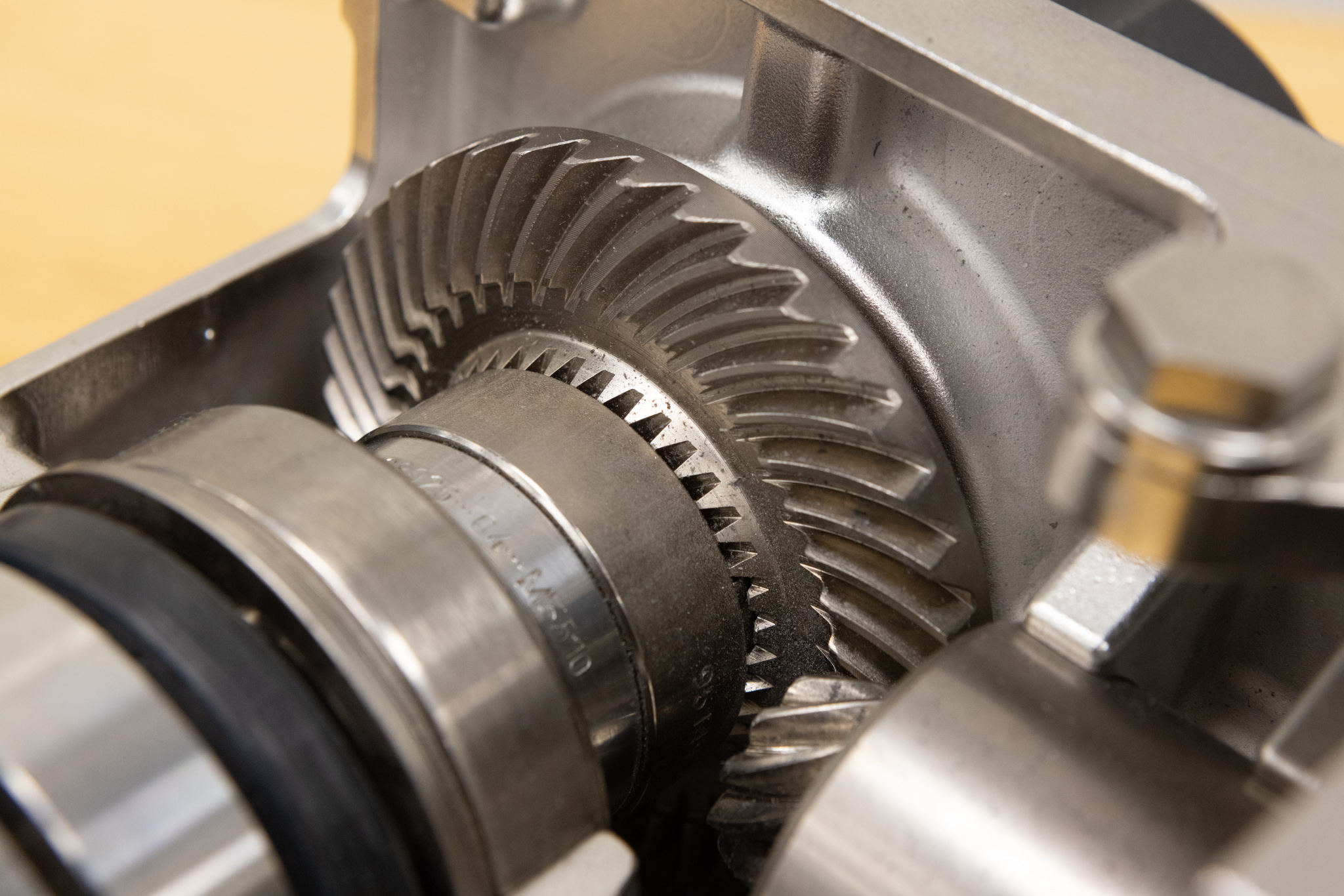

Common failure modes include the following:

- Bearing failures, such as spalling, brinelling, cage damage, or other problems that often trigger secondary gear damage.

- Gear tooth failure, including micropitting, macropitting, scuffing, or tooth root bending fatigue.

- Breather and gearbox seal failure that allow oil contamination or water ingress.

- Shaft and coupling issues tied to bending, torsional fatigue, misalignment, or similar underlying issues.

- Lubrication system breakdown, where the oil can no longer protect or cool components.

Some failures are sudden, like a cracked gear tooth after shock loading. Others are progressive, where surface distress slowly becomes vibration and heat, then a total shutdown.

Planetary, helical bevel, worm, inline, and right-angle gearboxes each carry different risk profiles based on a few factors: load paths, sliding contact, heat dissipation.

In most cases, the “failed” component isn’t the true root cause. The real issue is usually overload, lubrication failure, contamination, or installation error that stressed the system long before visible damage appeared.

Tools like gearbox vibration analysis make those early mechanical changes visible, helping maintenance teams identify developing bearing or gear issues before they escalate into full failure.

Lubrication breakdown & contamination

A well-lubricated gearbox can handle high loads and long runtimes without unexpected wear. Its job is to separate metal surfaces, control temperature, flush debris, and prevent corrosion. When that film breaks down, wear accelerates fast.

Wrong or degraded gearbox oil is one of the most common causes of gearbox problems. Incorrect viscosity or additive packages reduce film strength under load. Underfilled gearboxes slip into boundary lubrication, while overfilled motors churn oil and trap air while running hot.

Extended intervals between preventative maintenance allow oxidation and sludge, along with additive depletion.

Oil contamination multiplies the damage: It typically enters through worn seals, damaged breathers, washdown exposure, or poor handling during service. Water ingress emulsifies oil and lowers load capacity, while promoting rust.

Solid particles in oil create abrasive wear and act as initiation points for gear pitting causes and bearing damage.

Early warning signs include:

- Darkened oil

- Burnt odors

- Visible metal fines

- Milky emulsions

A lab oil analysis can confirm trends — viscosity shifts, rising particle counts, and increasing water ppm — often long before obvious gearbox failure symptoms show up.

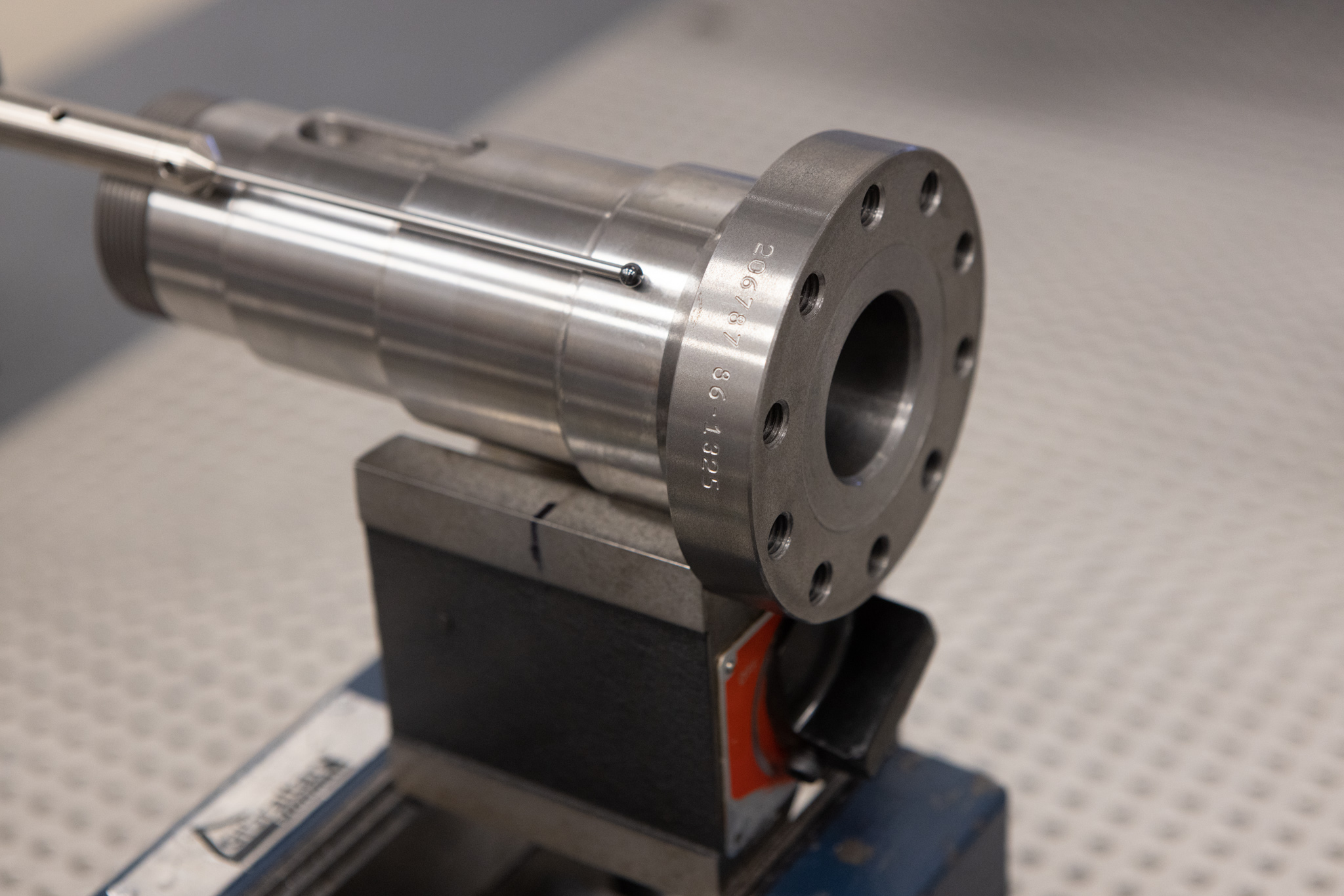

Misalignment, overhung loads, & installation errors

Alignment ensures the motor, gearbox, and driven equipment share true centerlines under real operating loads and temperatures, going well beyond being a simple startup task. Even small misalignment increases localized tooth stress and bearing edge loading.

Misalignment often shows up in a few ways: abnormal heat, noise, recurring seal leaks. Over time, uneven contact patterns lead to accelerated gear tooth wear patterns and shortened bearing life. Note that high-precision gearboxes are especially sensitive to these issues.

Overhung loads add another layer of risk. Belts, chains, rigid couplings, or cantilevered loads apply bending forces that exceed shaft design limits. These loads increase bearing stress and can cause shaft deflection, making gear mesh conditions even worse.

Installation mistakes are a frequent contributor: Soft foot, uneven mounting surfaces, incorrect fastener torque, improper coupling spacing, or ignoring thermal growth all set the stage for early failure.

Repeating issues, such as frequent seal replacement or unexplained vibration, tend to trace back to installation errors rather than the gearbox itself.

Overload, shock loading, & operating outside the rating

Gearboxes are rated for a torque spectrum, duty cycle, service factor, and thermal capacity, not just nameplate torque. Sustained overload reduces bearing life dramatically and increases the risk of tooth root fatigue.

Shock loading is even more destructive. Rapid starts and stops, jams, reversing loads, or indexing impacts create torque spikes that the gearbox never sees on paper. These events can cause scuffing and cracked teeth or brinelled bearings in surprisingly short timeframes.

System changes may introduce hidden overloads. Motor upgrades, VFD parameter changes, heavier product loads, or higher cycle rates all alter the torque profile. Even when torque looks acceptable, poor heat rejection can cause thermal overload.

High ambient temperatures, limited airflow, and washdown insulation effects all contribute to gearbox overheating causes. Evaluating the real duty cycle (and adding torque limiting or control strategies when needed) is a must for long-term reliability.

Wear, material fatigue, & environment-driven degradation

Not all gearbox wear is a failure. Even properly specified systems eventually reach fatigue limits. The problem is when environmental or operational factors accelerate that process.

Harsh environments are major contributors to industrial gearbox failure. Washdown and corrosive settings create rust pits that become fatigue starters. Dusty conditions raise particle counts and promote abrasive wear. Temperature extremes thin oil and degrade seals while reducing lubrication effectiveness.

Gearbox wear patterns often point to the following problems:

- Micropitting indicates inadequate film thickness, high sliding, incorrect oil selection, or similar issues.

- Scoring or scuffing suggests boundary lubrication combined with heat or shock loads.

- Uniform pitting often reflects sustained overload.

- Tooth root cracks indicate misalignment or excessive torque.

Recognizing these signs of gearbox failure early allows you to intervene with targeted corrective action, rather than reacting to catastrophic damage.

Building reliability instead of reacting to failure

Understanding how to prevent gearbox failure means looking beyond the broken part and addressing the system as a whole. Lubrication management, alignment discipline, realistic load evaluation, and environment-specific protection all play a role in effective gearbox maintenance.

Ignoring issues gives them time to escalate into problems that may require industrial gearbox repair and contribute to unplanned shutdowns or even cascade into motor damage and servo motor repair.

STOBER’s servo and industrial gearboxes are engineered with these realities in mind. Robust sealing options reduce oil contamination and water ingress. High-load gearing resists shock and fatigue, while flexible mounting and adapter configurations support proper alignment and real-world duty cycles.

Tools like the STOBER Configurator for reliable gearbox solutions help engineers select components that fit the application, not just the catalog rating, so gearboxes stay productive and predictable, while also remaining well-protected over the long term.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025