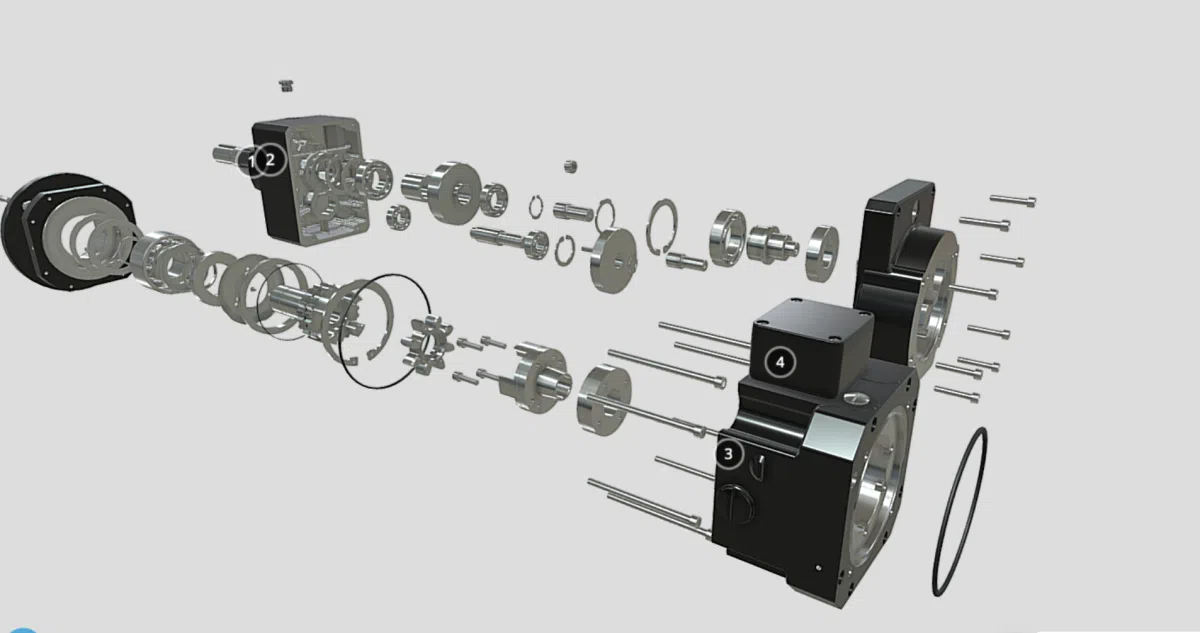

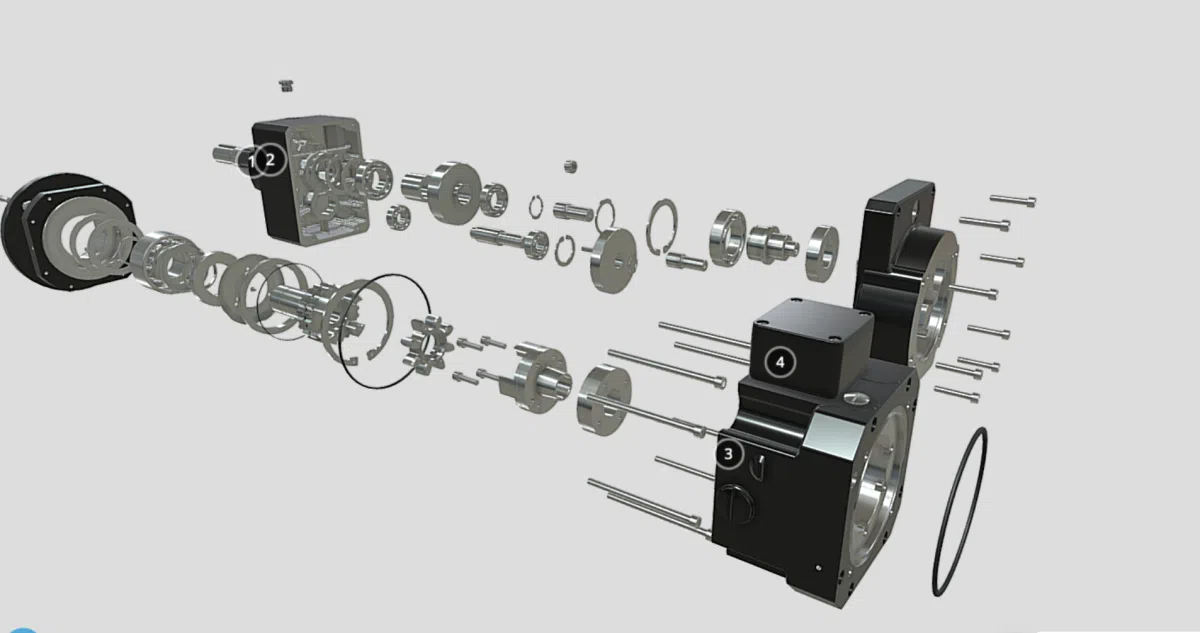

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gear units, you’re in luck—3D models of the product are now available on the STOBER website!

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gear units, you’re in luck—3D models of the product are now available on the STOBER website!

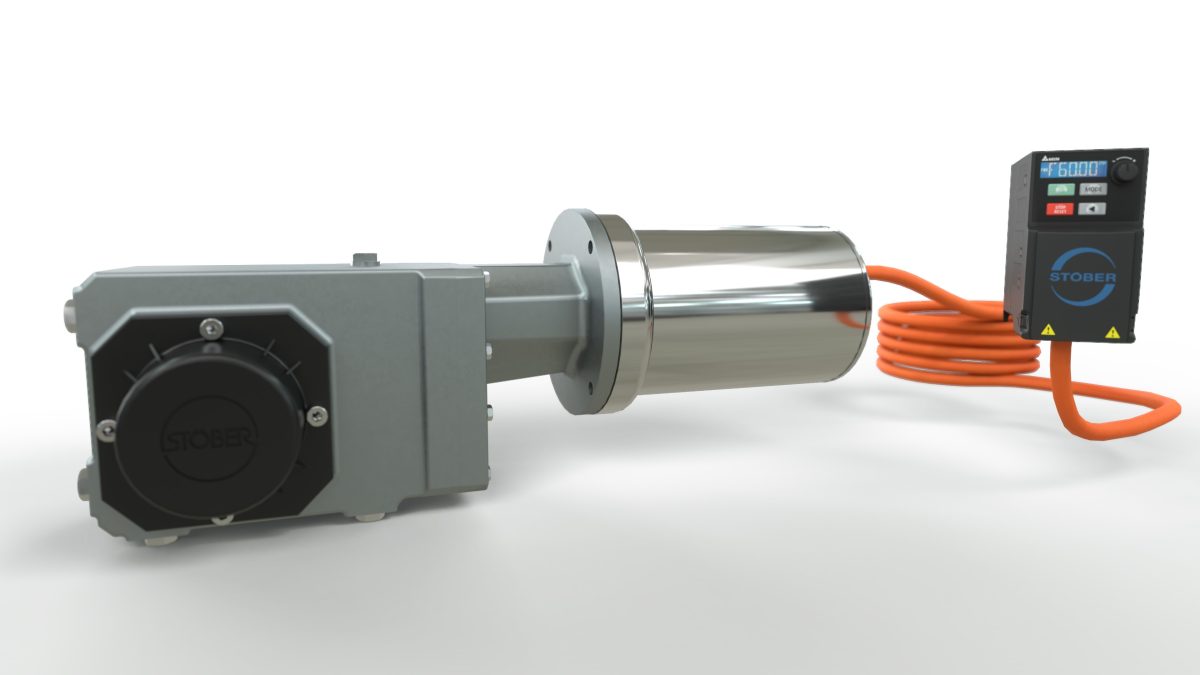

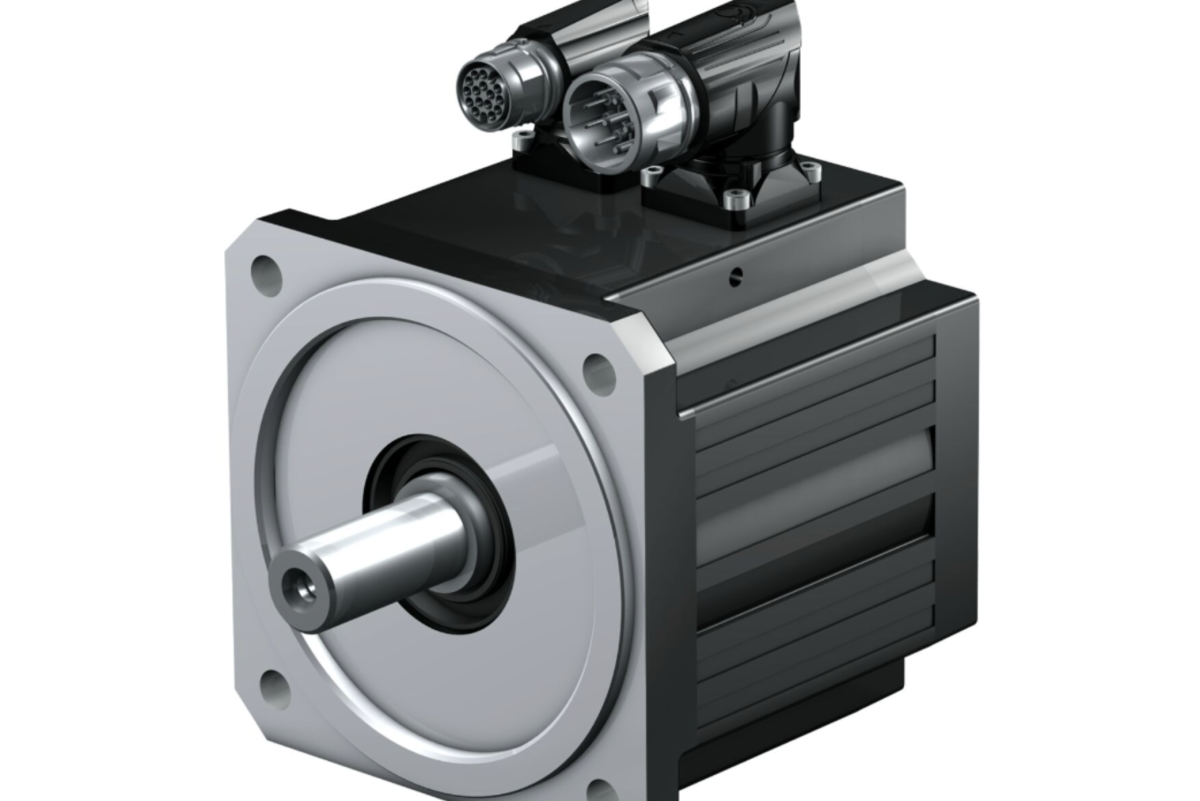

STOBER motors and geared motors are flexible in design and compatibility with third-party drives.

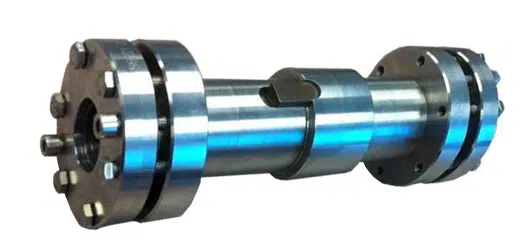

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

Are you frustrated with lead times for motors? STOBER has several options readily available from Maysville, Ky. Our Kentucky facility stocks the EZ3 (72mm frame size), EZ4 (98mm), EZ5 (115mm), and EZ7 (145mm) motors.*

We hope our blog has been informative, useful, and inspiring this year. As a review of 2023, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

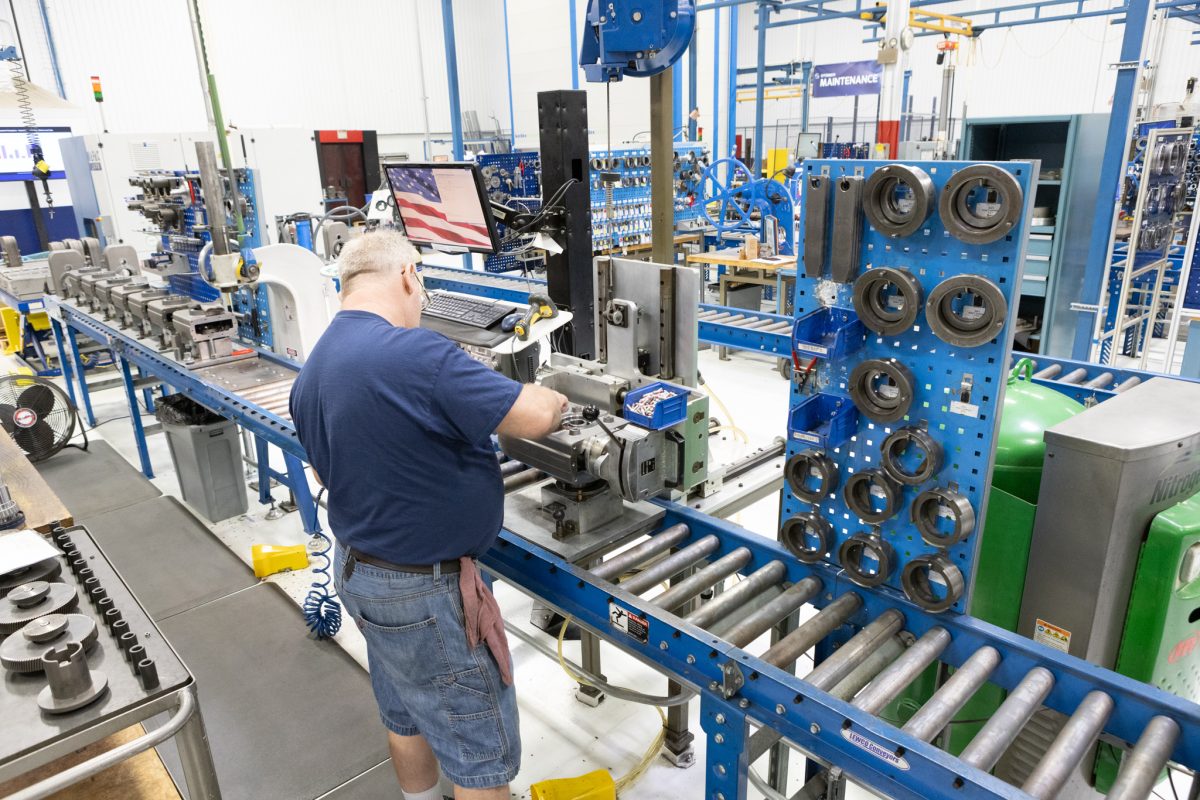

Food production is a harsh environment. While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

STOBER solutions can reduce space requirements in the packaging industry and minimize components and maintenance—a win-win situation! Innovative designs from STOBER can reduce equipment footprint by 20 percent.

STOBER’s quality paint mixture and painting process eliminates any worry about paint flaking. Every food duty unit is washed to remove any grease that could prevent paint from properly adhering to the surface. Then, each unit is painted with four layers of paint, including an antimicrobial clear coat.