Introduction to geared motors

Behind every smooth-running machine is a geared motor turning power into precision. It’s a specialized drive system that integrates an electric motor with a gearbox, so the two components function as one unit. Rather than assembling a standalone motor with external gearing, everything is engineered to work together.

This setup reduces complexity and improves reliability, while helping the entire system handle speed and torque demands more effectively.

The motor converts electrical power into rotation, and the gearbox modifies that rotation using mechanical reduction. That reduction determines output speed, available torque, and the system’s overall responsiveness. With the gearing built directly into the housing, you get consistent motion and predictable performance compared to pieced-together systems.

Geared motors show up in nearly every industrial environment you can imagine: automated conveyors, packaging equipment, machine tools, sorting systems, lifting mechanisms, and robotic equipment. They play a key role in industrial applications that need precise movement and controlled speed combined with reliable power transmission.

Proper selection ensures longer-lasting, more efficient systems. It also avoids overheating or wear, while allowing engineers to optimize performance and minimize maintenance and operational costs. Here’s a closer look at geared motors, including types, selection tips, key factors, and uses.

Common types of geared motors

You won’t find just one type of geared motor in industrial settings. Many are available, with each built around a different gear structure. The internal arrangement influences torque transmission, noise level, efficiency, and overall durability.

Helical geared motors

Helical gears use angled teeth that gradually engage, allowing smoother torque transfer and better noise reduction, along with greater overall efficiency. This design spreads loads more evenly across the tooth surface, reducing vibration and stress.

Applications that run continuously — like conveyor systems, blowers, mixers, or pumps — benefit from a helical gear design. The system stays quieter and lasts longer. These motors are especially valuable in high-speed applications where vibration and noise could otherwise interfere with sensitive operations.

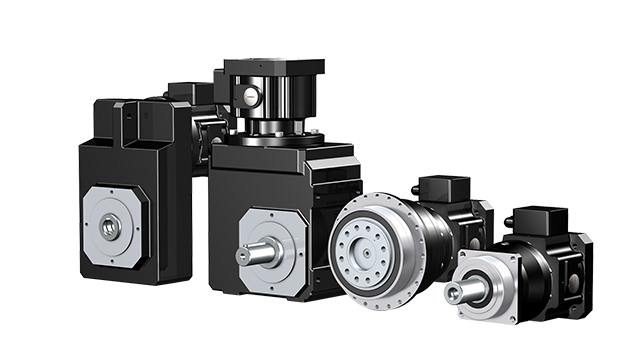

Bevel geared motors

Bevel gear systems are used when power needs to turn a corner. They transmit torque at 90 degrees, making it easy to design machinery with compact footprints or unusual layouts. If a machine requires a right angle gear motor configuration due to shaft placement or load path, bevel gearing is usually the preferred choice.

These motors are effective in packaging systems, conveyors, industrial automation, and other applications that require directional changes. The precision alignment of bevel gears also helps maintain gear motor performance over long operational hours.

Worm geared motors

A worm gear setup uses a worm screw and a worm wheel to create very high reduction ratios in a small footprint. It often provides a natural holding effect that can resist back-driving under many load conditions.

This makes the configuration ideal for lifts, hoists, gates, indexing systems, and conveyors handling heavy materials. While worm gears don’t offer the same high efficiency as other designs, their stability, compactness, and ability to self-lock under load make them extremely valuable. They’re particularly useful in applications requiring safety without additional braking mechanisms.

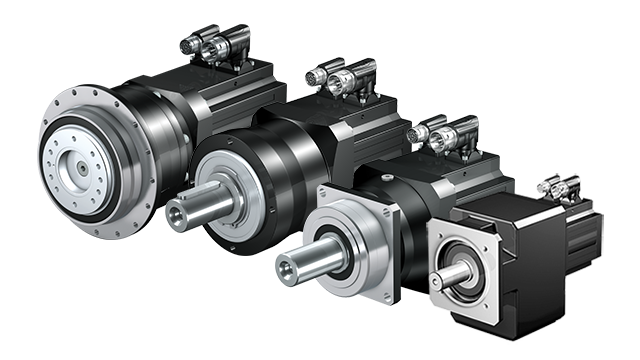

Planetary geared motors

A planetary geared motor arrangement uses multiple planets orbiting around a central sun gear. This evenly spreads the load, providing remarkable strength and delivering high torque output relative to size.

Planetary geared motors are common in robotics, automation tools, mobile platforms, and systems requiring precise positioning or rapid directional changes. They offer durability and compactness, along with excellent torque density. Their modular design also allows engineers to create custom geared motor solutions for highly specialized tasks, offering flexibility that few other designs match.

Hypoid geared motors

Hypoid gears operate similarly to bevel gears. But they allow torque to transmit between non-intersecting shafts. They’re known for quiet operation and long service life combined with strong efficiency.

Hypoid systems fit well into machinery where noise, smoothness, and space flexibility are top priorities. They’re often chosen for applications that need both high torque and low-speed control.

Inline vs. right-angle configurations

An inline gear motor connects the motor and output shaft on the same axis. That’s useful for simple layouts with minimal space constraints.

Right-angle designs, using hypoid or bevel gearing, redirect torque where machine geometry makes straight-line drive impossible.

Understanding which configuration best suits your machine is a major step in ensuring gear motor design considerations meet operational requirements.

Hybrid and custom arrangements

Some machines blend multiple gear types or use multi-stage arrangements to produce a very specific reduction ratio or torque profile. These hybrid systems, such as a helical bevel gear motor, show how adaptable gear motor design considerations can be when a machine needs custom behavior.

Advanced applications may even combine planetary geared motors with inline or right-angle stages to optimize torque distribution and efficiency or space savings simultaneously.

Here’s a quick breakdown of common gear motor categories:

- Smooth and quiet motion from helical gearing

- Direction-changing torque transmission with bevel gears

- Compact, high-reduction action from worm gears

- High torque density from planetary systems

- Quiet, angled power flow from hypoid gearing

How to select the right geared motor for your application

Choosing a drive system comes down to a few factors: torque, speed, space, environment, and alignment. A mismatch in any category can shorten motor life and cause mechanical wear, while creating unpredictable operation.

1. Torque requirements

Start with torque requirements. High loads may require a gear reducer or larger reduction ratio to produce the correct output. Too little reduction results in overheating, but too much slows down the machine.

2. Speed

Once the torque profile is known, consider your target speed and whether high or low output RPM makes sense for the design.

3. Physical layout

Space constraints determine whether you choose a compact parallel shaft gearbox, a right-angle housing, or an inline configuration. If the machine is tight on space, planetary or helical-inline systems often perform best.

4. Environment

Environmental factors also matter. Dust, moisture, chemicals, and washdown procedures all require different seals, housing materials, and IP ratings.

Stainless steel and aluminum housings offer corrosion resistance, while cast iron excels at mechanical durability. Attention to environmental protection often translates into extended motor life and reduced downtime.

5. Alignment

Confirm that the motor and gear stages match properly. Misaligned shafts or mismatched torque values cause premature failure and excessive heat, along with energy loss.

6. Other considerations

Engineers also need to evaluate duty cycle, peak loads, and operational frequency to ensure the selected motor meets long-term gear motor performance requirements.

Understanding geared motor efficiency and performance factors

Efficiency describes how effectively the system converts electrical power into useful mechanical output. Geared motor efficiency can range from roughly 70% at the low end to above 95% in optimized systems.

Factors influencing performance include:

- Load conditions and torque requirements

- Lubrication quality and the lubrication system used

- Material properties and manufacturing precision

- Operating temperature and ventilation

- Alignment accuracy and backlash tolerance

How different gear types compare

Worm gear designs generally land around 70–80%, since sliding friction produces heat. Helical systems reduce friction significantly and often run above 90% efficiency. Planetary systems take it even further, often reaching 95% or more. Bevel and hypoid gears fall somewhere in between depending on design.

Routine maintenance is a must for efficiency:

- Monitor oil condition.

- Check for contamination.

- Verify alignment.

- Choose the correct lubricant to reduce friction and improve mechanical performance.

These periodic checks ensure the motor continues delivering high torque without overheating or excessive vibration.

Even small improvements matter. Facilities running dozens of motors continuously can see large energy savings when they improve lubrication schedules or reduce backlash.

Optimizing reduction ratio choices and ensuring proper torque sizing also prevent wasted energy. The long-term benefits are many, including lower operational costs and more consistent system uptime.

Industrial uses of geared motors

Flexibility and reliability make geared motors a part of almost every industry.

Manufacturing and packaging

Conveyors, material indexing systems, wrapping machines, labeling equipment, and assembly tools rely on consistent, controlled motion.

A geared motor provides steady torque, even in demanding, continuous-duty environments. These systems often run around-the-clock, requiring efficiency and durability.

Food and beverage

Washdown-rated motors with corrosion-resistant housings are a must. These systems need to withstand cleaning chemicals, moisture, and high-pressure sanitization without failure.

Selecting materials that resist corrosion while maintaining high torque output ensures long-term reliability in wet or acidic environments.

Material handling

Lifts, sorters, AGVs, shuttles, and transfer systems rely on stable, predictable torque. Whether you’re moving bulk materials or positioning pallets, you need reliable motion control.

Inline or right-angle geared motors are often preferred for conveyors and lifts where space is limited.

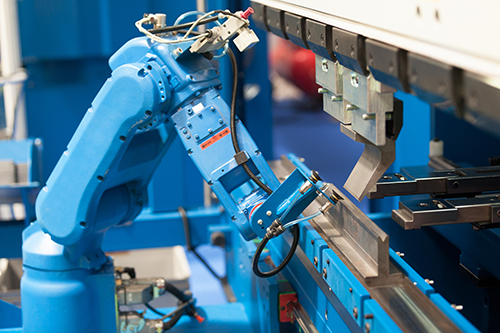

Printing, robotics, and automation

Quiet, smooth motion matters here. Planetary and helical systems thrive due to low noise and high accuracy combined with excellent longevity. Robotics especially benefits from good torque density and consistent positioning accuracy.

Modern automation also integrates feedback sensors, enabling smarter torque control and real-time monitoring. This improves efficiency and conditions equipment for predictive maintenance. The ability to integrate servo geared motor technology further enhances precision control in complex systems.

Advantages of using geared motors

A geared motor amplifies torque while reducing the size of the overall drive system. This allows smaller motors to move heavier loads without oversizing the entire machine.

Integrated gearing reduces misalignment problems, which are common issues when gearboxes and motors are mounted separately. Because many units use sealed lubrication, maintenance requirements drop significantly.

These motors also extend machine life, reducing vibration and lowering stress on bearings, while improving torque stability. Proper selection also leads to high efficiency and quieter operation, along with overall geared motor performance improvements.

Key advantages include:

- Higher torque from smaller motors

- Compact and space-efficient design

- Lower maintenance with sealed lubrication

- Reduced misalignment and smoother operation

- Quieter performance across most gear types

- Extended system life and lower long-term cost

Matching geared motor type to application

The right geared motor depends on torque demand, speed requirements, environmental challenges, and expected duty cycle. Understanding these factors means engineers can choose the configuration that keeps their system reliable and efficient for years.

A careful selection process ensures maximum performance from day one and minimizes long-term maintenance costs. Tools like the STOBER Configurator allow engineers to quickly evaluate multiple options and ensure the right configuration for their application.

Considering industrial geared motor types, environmental factors, and torque needs together helps avoid costly overhauls and ensures long-lasting, efficient operation.

If you’re comparing servo products or need help selecting the ideal drive system, you can always contact STOBER at (888) 786-2371 or email sales@stober.com for application-specific guidance.

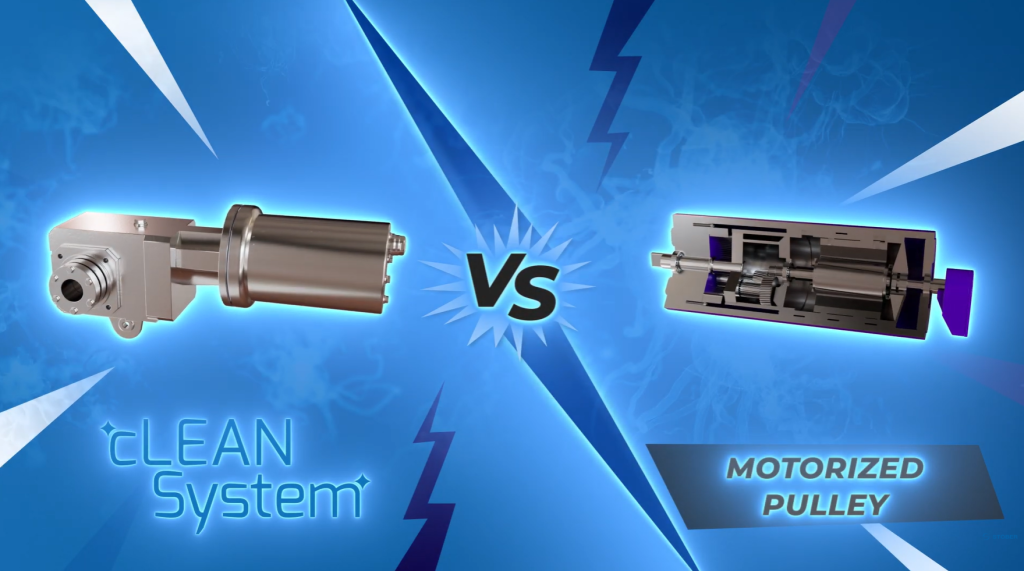

STOBER cLEAN System outperforms motorized pulley in food processing environments

STOBER cLEAN System outperforms motorized pulley in food processing environments  Ideal gearbox selection: Practical sizing checklist to save money

Ideal gearbox selection: Practical sizing checklist to save money  STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

Selecting gearboxes for robotic & industrial automation systems