Industrial gearbox maintenance extends the service life of gearboxes, including maintaining torque and speed performance, and preventing unplanned downtime and gearbox failure. Effective gearbox maintenance combines sound lubrication practices, careful monitoring of operating conditions, and informed decision-making about repair, rebuilding, or replacement of gearbox components. Maintenance personnel can significantly improve the reliability, efficiency, and lifecycle cost of every industrial gearbox in the plant.

Industrial gearbox maintenance fundamentals

Industrial gearbox maintenance protects the gears and bearings from wear, maintains torque output and efficiency, and reduces the risk of sudden gearbox failure. It also keeps the oil clean and at the correct level, manages gearbox temperature, and preserves seals and housings.

These goals translate directly into higher uptime, safer operation, and lower total cost of ownership for critical equipment. Operating conditions, particularly load and environment, have a direct impact on wear rates and inspection requirements.

Steady-state loads are less demanding, while variable or shock loads significantly increase stress on gears and bearings, which increases fatigue and requires more frequent inspection. Humidity, airborne dust, abrasive particulates, and caustic washdown chemicals attack seals, coatings, and paint, undermining corrosion resistance and compromising ingress protection (IP) ratings. The result is that gearboxes in harsh environments require more frequent maintenance and checks.

Establish a solid baseline for the health of the gearbox by:

- Capturing temperature at normal load, vibration levels across key frequencies, oil cleanliness, and viscosity

- Taking alignment readings as reference values

Over time, deviations from this baseline, including higher vibration, increased temperature, or worsening oil sample results, will serve as early warnings of impending issues.

Lubrication is the most crucial factor in gearbox maintenance. The right lubricant type, viscosity grade, and additive package minimize metal-to-metal contact between gears and bearings, controls friction, and stabilizes temperature.

Preventive maintenance for industrial gearboxes

Clearly defined, time-based tasks create a strong gearbox preventive maintenance program. Daily routines typically include:

- Quick visual checks for leaks

- Abnormal noise or vibration checks

- Checks for visible damage

Monthly tasks include checking the oil level, sight glass clarity, and breather condition. Quarterly tasks include checking fasteners for proper torque and inspecting the condition of the shaft coupling.

Finally, create an annual checklist that covers mounting, alignment, internal gear wear, and overall performance for industrial gearbox service.

Oil and filter changes and top-off follow a gearbox lubrication schedule based on operating hours, duty cycle, and environmental severity. When changing the oil, ensure you use the proper ISO viscosity grade and the type, whether synthetic or mineral-based, pursuant to the manufacturer.

Breather maintenance is equally important. Clogged or undersized breathers allow moisture ingress and pressure buildup, causing seal damage, oil contamination, and premature need for gearbox seal replacement.

Proper installation and alignment are often the differences between long, trouble-free operation and chronic failures. Misalignment between the motor and gearbox shafts creates excessive vibration, additional radial and axial loads, and uneven gear tooth loading, all of which increase wear and reduce efficiency.

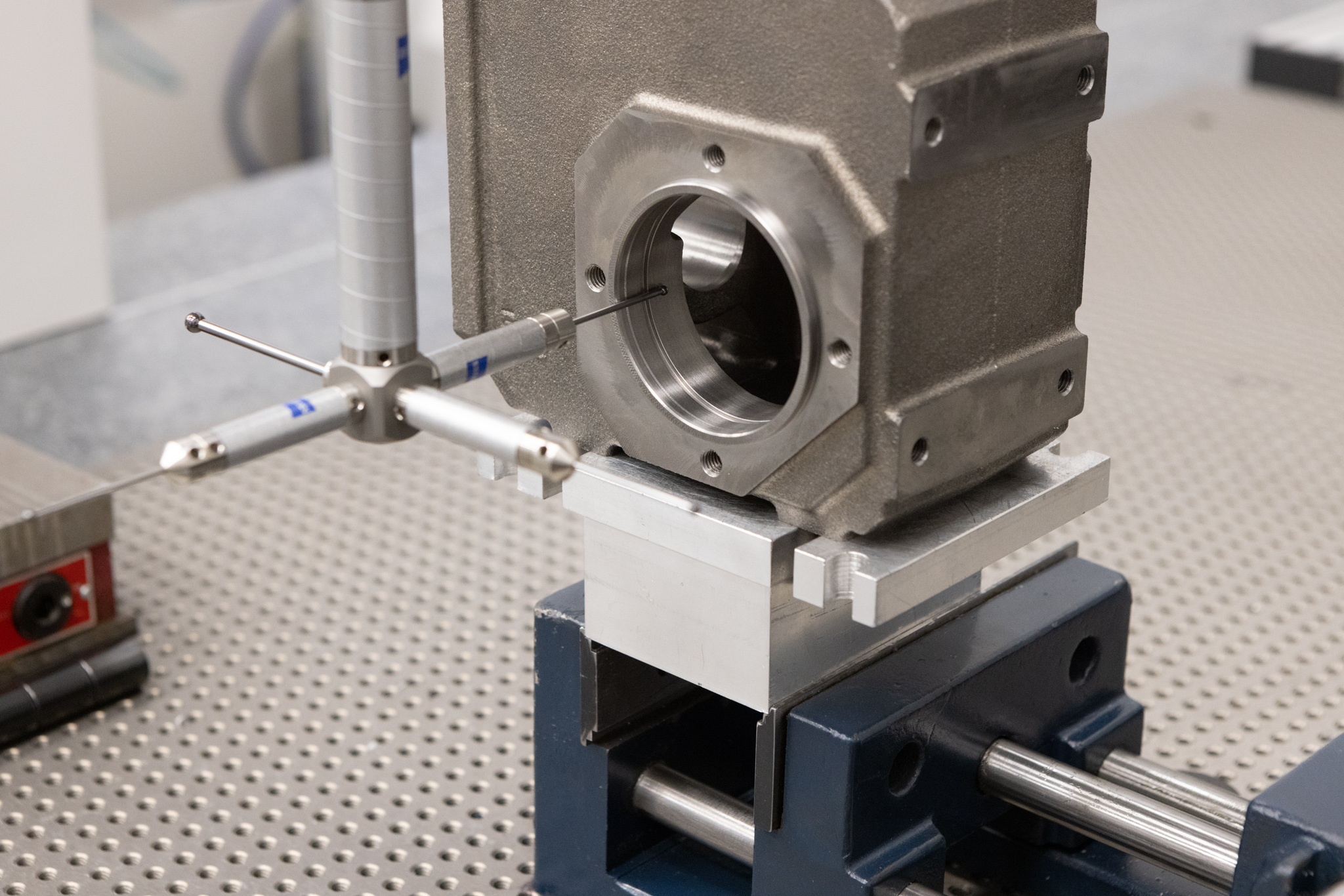

Using quality gearbox alignment tools, such as dial indicators or laser alignment systems, helps ensure coupling faces and shafts remain correctly positioned, which reduces energy losses and extends the life of bearings, seals, and gears.

Keeping exterior surfaces clean isn’t only cosmetic; it dissipates heat more effectively, improving thermal management and making cracks, oil trails, or loose hardware easier to spot during inspection.

Documentation of gearbox maintenance

Always document gearbox maintenance, including every torque reading on critical fasteners and lubricant change. Record the inspection findings and tie them to a specific asset. Over time, these maintenance records allow reliability and maintenance personnel to adjust intervals, identify recurring issues, and refine standards for gearbox preventive maintenance.

Plants can also draw on external guidance, such as the importance of maintenance for gearboxes, to benchmark their internal procedures against industry norms.

Predictive maintenance techniques for gearboxes

Predictive maintenance focuses on identifying changes in condition that signal failure, which allows you to schedule repairs during planned downtime rather than after a breakdown. Vibration monitoring is one of the primary tools in gearbox condition monitoring because each fault type generates a characteristic amplitude and frequency pattern.

By trending vibration signatures over time, technicians can detect gear wear, bearing defects, imbalance, and misalignment before they cause severe damage.

Oil sampling is another critical predictive maintenance technique. Lab or on-site analysis of lubricant can reveal metal particles from gears and bearings, dirt and moisture ingress, oxidation products, and additive depletion.

When you combine trending vibration signatures and oil sampling with a gearbox inspection checklist, you can better pinpoint internal problems like pitting, micro-spalling, or advanced wear without opening the housing.

Thermographic inspection and routine temperature trending add another layer. Infrared images and logged temperatures expose hotspots potentially caused by overloading, misalignment, inadequate lubrication, or restricted cooling.

Modern predictive programs often employ industrial internet of things (IIoT) sensors and predictive maintenance software to collect and analyze data automatically. IoT-enabled devices mounted on industrial gearboxes can continuously measure vibration, temperature, and sometimes oil quality parameters, feeding information to a central platform that triggers alerts when trends exceed defined limits.

Integrating these systems with a Computerized Maintenance Management System (CMMS) supports condition-based maintenance, including work orders, inspections, and even spare-part reservations.

Incorporating mean time between failures (MTBF) as a core performance metric also strengthens gearbox reliability programs. Tracking the average operating time between breakdowns helps maintenance teams evaluate asset health, adjust service intervals, and measure the long-term effectiveness of preventive and predictive strategies.

Common gearbox problems and troubleshooting

Even with excellent planning, you can still have problems with industrial gearboxes, and rapid gearbox troubleshooting is essential. The most frequent causes of gearbox malfunction include lubricant contamination, inadequate or incorrect lubrication, bearing fatigue, gear tooth wear, and seal degradation.

Misalignment, overload, and poor installation practices can also create one failure after another and transform a minor defect into a major gearbox repair. It is imperative to conduct regular inspections and gearbox temperature monitoring to catch issues prior to failure.

Early failure symptoms are often straightforward and can include:

- Abnormal noise (whine, rumble, or knock)

- Elevated vibration

- Temperature spikes

- Foaming or discolored oil

- Visible oil leaks at seals or gaskets

When technicians observe these warning signs you need industrial gearbox repair, confirm operating conditions, isolate the gearbox if possible, and perform basic checks on oil level, breather condition, and external alignment.

Stroboscopes, portable vibration analyzers, and borescopes enable internal visual checks for gear scoring, pitting, or cracked teeth without complete disassembly.

Avoid secondary damage by taking immediate corrective actions. If oil is contaminated, flush the gearbox, replace the filters, and determine the root causes of contamination, whether failed seals, open breathers, or poor fill practices.

- Align the misaligned drive train and replace any worn bearings or couplings.

- Replace failed seals to prevent lubricant loss and ingress of water or dirt.

- Ensure proper torquing of fasteners to avoid new stresses.

- Analyze the root cause of the issue to determine whether the gearbox suffered overload, was installed improperly, or had lubrication issues or design limitations.

Repair, rebuild, or replace – making the right decision

If a gearbox suffers severe damage, you may need to replace the gearbox instead of going through another repair cycle. In some cases, you may be able to rebuild it, depending on your findings when you disassemble it. If rebuilding, replace worn or damaged parts and replace all of the seals. Once rebuilt, ensure the gearbox tests to the original equipment manufacturer (OEM) tolerances.

You can also upgrade gearboxes during replacement cycles due to advances in materials and design. Modern units have benefits such as case-hardened or nitride steels, improved surface finishes, and better sealing systems that help boost efficiency and reduce heat generation. Some upgrades may minimize some of the traditional requirements for oil changes and routine industrial gearbox maintenance services. However, we recommend structured gearbox maintenance best practices, regardless of the age of the gearbox.

Try the STOBER Configurator or get in touch with our team for personalized recommendations. To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

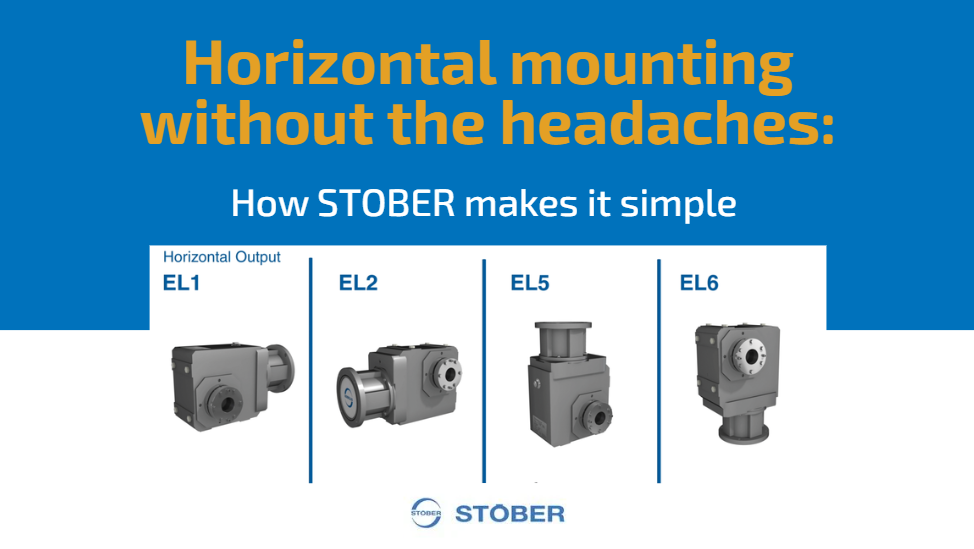

Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory