Choosing the right gearboxes for automation is one of the biggest decisions in robotic and industrial system design. The gearbox reduces speed and directly shapes accuracy, throughput, reliability, and the long-term cost of running your equipment.

In modern motion control systems, gearboxes sit between high-performance servo motors and real-world loads. That makes them the mechanical link that determines whether automated machines are precise and responsive or sluggish and unstable.

As automation systems become faster and more compact, gearbox performance increasingly defines the ceiling for what a machine can accomplish. Even the best motor and controller can’t compensate for a poorly matched mechanical drivetrain.

The following guide walks you through how to select the right gearboxes for your organization’s automated systems.

Gearboxes for industrial automation: Why selection matters in robotic systems

Automation gearboxes aren’t generic reducers; they operate in environments with fast cycle times and frequent reversals, along with 24/7 duty, putting far more stress on gears and bearings than traditional machinery.

When gearbox selection goes wrong, the consequences usually show up in a few places:

- Throughput: The system can’t hit target cycle time without overheating or stalling.

- Accuracy and repeatability: The robot drifts and overshoots or struggles to hit the same point consistently.

- Uptime: Bearings wear early and backlash grows, while unplanned downtime becomes routine.

An oversized gearbox creates its own problems: You pay more upfront, add mass to the joint, increase inertia, and slow acceleration and deceleration. This extra inertia also forces servo gearboxes and motors to work harder, increasing energy consumption and tuning complexity.

An undersized gearbox is worse: Thermal overload, gear tooth fatigue, bearing failure, and premature backlash growth are almost guaranteed. In high-speed automation, even small sizing errors get amplified over thousands or millions of cycles.

A mismatch in architecture is another common mistake. For example, using a low-efficiency right-angle design when you really need a high-efficiency right angle planetary gearbox or helical-bevel unit can quietly drain energy and kill precision.

That’s where optimized selection matters. Rather than forcing a catalog part into the system, STOBER focuses on translating real application data into the right architecture, sizing, and integration, balancing performance and cost from day one.

Key automation demands gearboxes must handle

Robotic systems rarely see smooth, steady loads. Most automation applications have aggressive motion profiles and constantly changing forces.

Typical load patterns include high acceleration and deceleration, repeated indexing, frequent reversals, and short-duration peak torque events from gripping and lifting or collisions. Even moderate loads can generate extreme stress when they’re repeated thousands of times per shift.

These demands translate into very specific gearbox requirements:

- High-torque density keeps joints compact and reduces inertia, directly improving dynamic response.

- Low backlash and high torsional stiffness are needed for precision positioning, especially in servo-driven axes.

- Thermal capacity matters since heat builds up quickly in high-cycle systems, even with modest average torque.

- High efficiency limits energy losses and protects long-term reliability.

Validating both continuous torque and peak torque against the duty cycle is also important. Many failures happen when the gearbox can handle average load but not the repeated peaks that occur during acceleration, braking, sudden direction changes, and similar movements.

Real-world automation gearbox selection should always start from the load side. Mass, radius, speed curve, and duty percentage matter far more than motor nameplate data. The gearbox “feels” the real mechanical load, not the theoretical motor capability.

Choosing the right gearbox architecture for automation

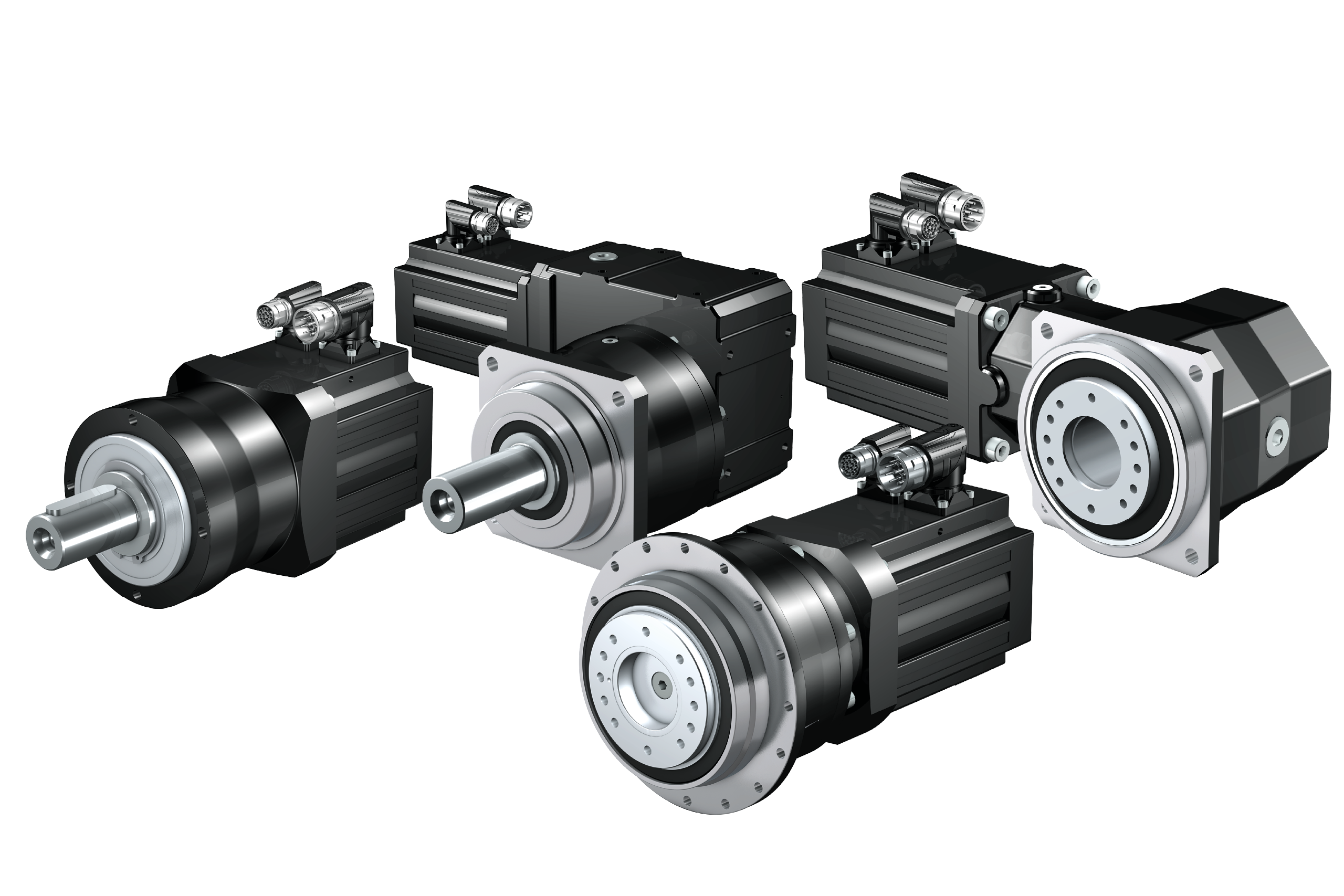

Planetary gearboxes

The planetary gearbox is the most common choice in robotics. Its compact design and high stiffness, along with the ability to use multiple planet gears, make it ideal when you have limited space and high torque demand.

If you’re unfamiliar with how planetary gearboxes work, the basic idea is that multiple planet gears rotate around a central sun gear and share the load through a surrounding ring gear.

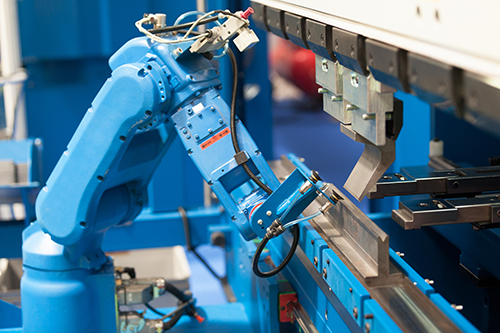

You’ll see planetary gearboxes for automation in robot joints, rotary tables, indexing heads, and servo-driven axes. They’re often used as servo gearbox for automation systems since they combine low inertia with excellent dynamic response.

Precision planetary gearbox automation designs also distribute load across several gears, improving torque capacity and allowing for smaller, lighter housings. This is a key reason they dominate collaborative robots and articulated arms.

The main tradeoff is cost. A planetary system is more expensive than a simple spur gearbox or spur gears, and it requires proper sizing to avoid fatigue from peak loads.

Helical gearboxes

Helical gearboxes are typically used in smoother, continuous-duty applications, such as conveyors, process lines, and material transport systems. The angled teeth distribute load gradually, making them quiet and efficient yet durable.

They’re not as compact as a planetary unit for the same torque, but they offer long life and excellent efficiency for steady loads. In many plants, they form the backbone of reliable, low-maintenance drive systems.

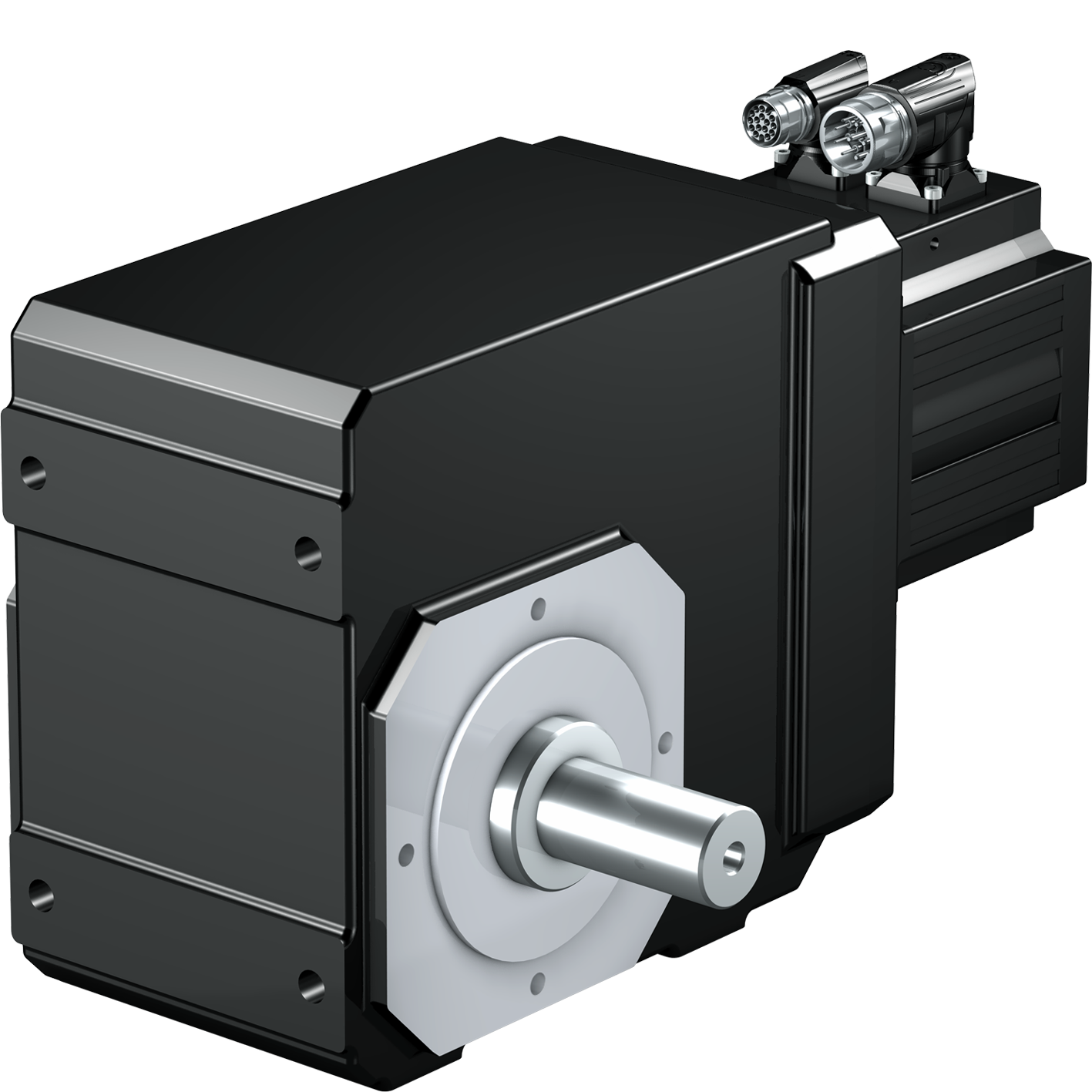

Helical-bevel and right-angle gearboxes

When the layout requires a 90-degree power transfer, a right angle gearbox becomes a must. Helical-bevel designs maintain high efficiency while changing direction, making them ideal for transfer stations, spiral conveyors, compact automation cells, and similar applications.

Compared to worm designs, helical-bevel and right angle planetary gearbox systems provide far better efficiency and are much more suitable for precision applications where heat and backlash matter.

Overall, the right architecture always comes after defining output speed, torque range, required precision, and available space.

Ratio, speed, and precision: Getting motion right

The gear ratio defines how motor speed and torque are translated into real motion. In automation, ratio selection is a chain: Necessary output speed determines the ratio, and that requires validating it against continuous and peak torque during acceleration and braking.

Precision in automation shows up as how fast a system settles and how repeatable it is, along with how stable it feels under load.

Backlash is the most visible metric. A low-backlash gearbox reduces positional slack that causes common issues – overshoot, oscillation, and longer settling times. Lost motion combines backlash, elasticity, and control response into a single measure of real-world accuracy.

Packaging and assembly robots usually require precision gearboxes with extremely low backlash and high torsional stiffness. Material handling systems may tolerate more backlash but need higher torque and durability.

Oversizing isn’t the solution to precision problems: A larger high-precision gear reducer adds inertia and cost. The smarter approach is selecting the correct precision class and stiffness level within the right gearbox family.

Extreme ratios can also hurt performance. Very high ratios increase reflected inertia and make servo tuning more difficult, leading to control lag, overshoot, unstable control behavior, and other problems.

Service factor, shock loads, and lifecycle reliability

Automation environments push service factor requirements higher than most mechanical systems.

High cycle counts, variable payloads, frequent emergency stops, indexing shocks, and occasional collisions all multiply the stress on gears and bearings. Temperature extremes and harsh environments make it worse.

Shock loads are common in real plants. A robot picks a part that’s stuck, or a conveyor jams. A pallet might misalign. These events may only last milliseconds, but they dominate fatigue life and often determine when a gearbox actually fails.

Long-term reliability depends on two factors. The service factor must reflect real duty severity, and bearing and gear tooth life must be calculated using the full load spectrum, not just average values.

Undersizing leads to early wear and expensive downtime, while oversizing increases capital cost and reduces efficiency. A properly sized high-cycle gearbox hits the sweet spot between durability, performance, and cost.

Environment, mounting, and integration in automated cells

The operating environment often dictates the final gearbox model more than torque or ratio:

- Washdown and food applications require corrosion-resistant housings and sealed designs, along with food-grade lubricants

- Dusty or abrasive environments demand robust sealing and breathers.

- Cleanroom and pharmaceutical systems need low particulation and easy-to-clean surfaces.

- Outdoor systems must handle temperature swings and humidity, along with condensation.

Integration issues are just as important. Mounting orientation affects lubrication and thermal behavior. The output shaft interface influences stiffness and backlash, along with bearing loads. External radial and axial loads from belts or sprockets need to stay within gearbox limits.

Space envelopes and cable routing often force architecture changes late in the design process. That’s why you should validate the environment and integration before finalizing torque and ratio.

Ignoring these factors early is one of the most common causes of late-stage redesigns in automation projects.

Efficiency and total cost of ownership in automation

Efficiency matters more in automation than in almost any other industry. Dozens of servo axes running continuously mean small efficiency differences become major energy costs over time.

Higher efficiency reduces heat, extending lubricant life and protecting bearings. That directly lowers maintenance intervals and reduces failure risk.

The true total cost of ownership includes more than the purchase price. In automation, the main cost factors often include:

- Purchase cost of the gearbox itself

- Energy cost over the system’s operating life

- Maintenance and lubrication intervals

- Replacement parts and labor

- Downtime cost from lost production

- Quality losses from drift, vibration, and backlash growth

A cheaper gearbox can easily become the most expensive component in the system if it causes line stoppages or precision issues. Efficient, well-sized robotic automation gearboxes often pay for themselves (many times over) through reduced downtime and stable performance.

Application examples and a simple selection workflow

In real equipment, gearbox selection looks like this: A robot joint or rotary axis usually uses a compact high-torque gearbox, typically a precision planetary with low backlash, high stiffness, and peak-torque capacity that’s carefully verified.

A gantry or linear transfer drive may use planetary or helical, depending on acceleration severity and available space. Continuous conveyors favor helical inline designs for smooth operation and long life, while a right-angle transfer cell often uses helical-bevel for layout efficiency without the losses of worm drives.

A simple first-pass workflow helps avoid mistakes:

- Define the load and motion profile, including continuous load, peaks, and duty cycle

- Pick architecture based on torque density, precision, and layout

- Set ratio and torque targets

- Apply service factor and validate life and thermal limits

- Confirm environment, mounting, and shaft loads

- Check precision class against the task

When you have uncertain load factors or tight integration constraints, it’s time to bring in a specialist. The STOBER Configurator makes it easier to translate application data into real gearbox models. Contact STOBER today to work directly with experts and prevent costly redesigns later.

Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices