Synchronous and asynchronous motors can provide precise speed control and general power to your applications, making them the bedrock of alternating current (AC) motor technology. When direct current (DC) motors are liable to lose energy across the application, synchronous and asynchronous motors both augment your alternating current and help control output at any given stage of the application.

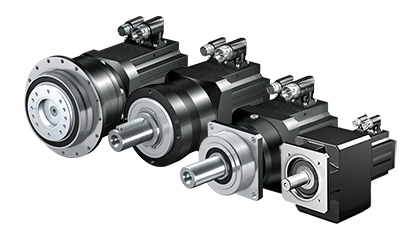

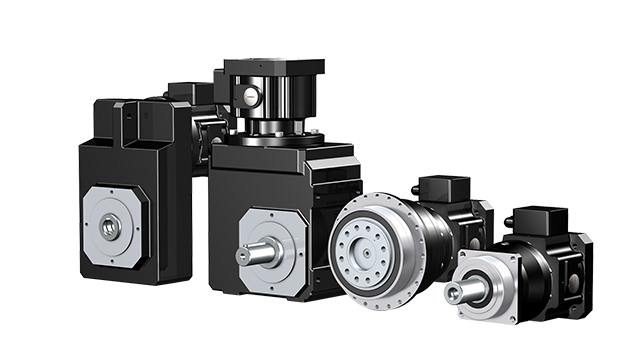

Understanding the difference between these types of motors is also key to grasping how modern synchronous servo systems achieve precise motion control. At STOBER, these motor principles form the foundation of our servo drives and gear solutions, where advanced feedback and control technology build on classic AC motor designs to deliver accuracy, efficiency, and reliability in demanding automation environments.

As your electric motor converts energy to mechanical power, the right foundation improves efficiency, performance, and lifespan. If you’re searching for the difference between synchronous and asynchronous motors, we’ll look at the basics of how motors work, including common types, industrial uses, and working principles.

What is a synchronous motor? Working principle, features & benefits

A synchronous motor runs at the same speed as the magnetic field. The rotor may contain permanent magnets or electromagnets that lock with the rotating magnetic field. This locking mechanism ensures continuous operation, meaning constant speed even at high loads, and relatively reliable power factor corrections.

Used in industries like automation and aerospace, these motors provide energy efficiency at steady speeds and can adjust to unexpected spikes (albeit with some tight limitations).

Synchronous AC motors are fairly expensive and typically require either damper winding or a pony motor to start, meaning you’ll need to purchase additional equipment to get them going.

Plus, while they are generally reliable, the synchronous motor working principle can make them sensitive to voltage fluctuations.

What is an asynchronous motor? Induction motor design & operation

An asynchronous motor is a type of induction motor with a slower speed than the magnetic field. The magnetic field induces the current in the rotor, creating the relative torque characteristics. Constructed using a stator with alternating current windings and either a squirrel cage or wound type rotor, its speed is controlled by its supply frequency.

The asynchronous motor is simple, durable, affordable, self-starting, and reliable under variable loads. However, it doesn’t have the same precision as a synchronous motor, making it less energy efficient. It’s typically used for broad industrial applications, like fans, pumps, and general manufacturing equipment.

Synchronous vs. asynchronous motor: Key differences explained

An asynchronous motor has slip, or a difference in speed to the magnetic field, that allows it more torque flexibility under heavier loads, while a synchronous motor has a more limited torque range given its precision sync.

You can think of an asynchronous motor as a rugged workhorse without the same precision or agility as its synchronous counterpart. Asynchronous motors have a simple design, an attractive upfront cost, and self-starting capabilities. Synchronous motors are great for steady loads at constant speeds, while asynchronous motors are better for variable loads (even though they sacrifice energy efficiency).

Synchronous motor applications are usually precision tasks, like those needed for clocks or robotics, while asynchronous motor applications are for broader use, such as conveyors or mills.

Industrial applications of synchronous and asynchronous motors

When precision timing matters, synchronous motors are the clear choice. For example, a synchronous motor can be used to power a centrifugal compressor in an oil plant, ensuring precise movement in a large-scale operation. This can not only lead to more efficient output during high production periods, but it can also cut back on dangerous vibrations or resonance that threaten your employee safety and put expensive equipment at risk.

An asynchronous motor’s stator winding makes it more suited for general industrial applications. That slight dip in speed will have little impact on broader equipment, like pumps, elevators, or machine tools. It’s easy to see why induction motors dominate the market, accounting for around 90% of AC motors used in industrial applications. They offer strong returns on investment, even in high-demand industrial settings.

How to choose between synchronous and asynchronous motors

Here, we’ll look at some key decision criteria:

- Torque: If you expect your torque needs to vary across the application, an asynchronous motor reduces your odds of failure. That said, if the slip differential is too high, you can still damage the motor during peak production.

- Speed regulation: Synchronous motors do have some flexibility, but in general, they’re designed for very precise applications. If you need a motor for varying loads, the asynchronous motor working principle makes it the better option.

- Environment: Synchronous motors have a more complex design, ensuring reliability in precision applications with proper control and maintenance, but they are more sensitive to environmental threats like dust or condensation. If your motor faces harsher weather conditions, consider the asynchronous motor’s simpler, more durable design.

- Downtime: Both asynchronous motors and synchronous motors can translate to unscheduled production downtime. If your synchronous motor is liable to be clogged with dust or subjected to heavy loads, it can result in malfunction. Excessive slip from overload can overheat and damage the motor.

- Maintenance: Synchronous motors are precise machines, meaning you’ll need some expertise when it comes to basic motor services like installation and repairs. An asynchronous motor only has a few core components that are usually easier to service, which typically translates to fewer and faster service sessions throughout its lifespan.

- Energy efficiency: Asynchronous motors can handle fluctuations in load, but the trade-off is that these motors can lose efficiency as they adjust. A synchronous motor, especially in reliably consistent applications, is more energy efficient thanks to its precision.

- Cost: Asynchronous motors typically offer lower upfront costs and long operational lifespans; meanwhile synchronous motors usually demand higher initial investment and may have higher utility costs over extended use.

Choosing the right motor with confidence

In some applications, it may be obvious which motor to choose based on whether constant synchronous speed is required. However, more often you’ll get stuck in a grey area, especially if you’re weighing environmental factors against cost and durability. As you get deeper into industrial motor comparison, it helps to work with a partner who can help you foresee not just the advantages, but the compromises that you might have to make along the way.

Understanding how AC motors operate helps explain how modern servo systems build on these principles. STOBER integrates these fundamentals into high-precision servo gear and motor designs for automation applications. It’s our job to both supply trusted devices and steer customers in the right direction.

Try the STOBER Configurator or get in touch with our team for personalized recommendations. To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025