Mounting a gearbox shouldn’t feel like solving a puzzle — but for many plants and OEMs, that’s exactly how it goes. You’ve probably seen it before: teams huddled around a print, rotating a gearbox like it’s a Rubik’s Cube, arguing about orientation arrows, lubrication levels, and which “approved” position won’t cause premature failure.

It’s the industrial version of the Spiderman pointing meme — everyone pointing at everyone else, no one totally sure what’s correct. And in many cases, they’re all right…because with most gearboxes, mounting direction does matter. A lot. But with STOBER, it doesn’t have to.

In fact, STOBER gearboxes are intentionally engineered to make horizontal mounting straightforward, flexible, and error‑proof — freeing your team to focus on productivity rather than position charts.

Why horizontal mounting gets complicated (with other gearboxes)

Traditional gearbox designs come with hidden rules that installers must navigate:

1. Limited “approved” mounting positions

Competitor units often require one of only a few clocked positions to avoid lubrication starvation. Mount them slightly off-angle? You could shorten the life of the gearbox from day one.

2. Orientation-sensitive seals and vents

Installers may need special vents, rotated housings, or added ports just to make a gearbox safe to run in a certain direction.

3. Increased risk of user error

The more “rules” a gearbox has, the more likely someone — especially in tight spaces or rushed shutdown scenarios — misinterprets the mounting requirements.

4. More time, more labor, more scrap

Every field modification, extra part, or rework adds cost and throws off schedules. Horizontal mounting shouldn’t take a committee meeting to figure out — and that’s exactly why STOBER refuses to overcomplicate it.

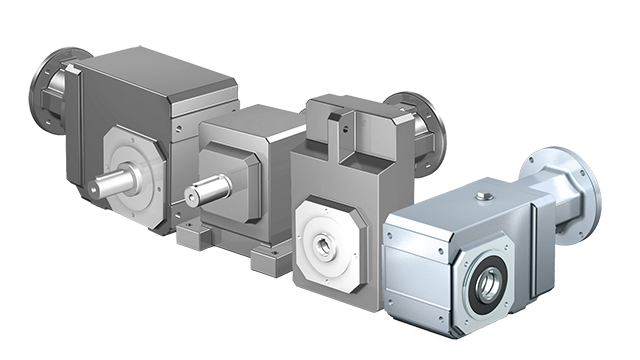

The STOBER difference: True any‑horizontal mounting

STOBER gearboxes are designed from the inside out to eliminate mounting uncertainty. Whether your team is working on a conveyor line, a washdown application, or a compact OEM build, STOBER makes installation simple.

Here’s how:

1. Mount it how you want — No restrictions*

STOBER gearboxes can be mounted in any horizontal orientation. Installers don’t have to worry about “approved” angles, rotating housings, or strict alignment positions. If the layout demands a nonstandard angle or tight corner? No problem.

2. Built‑in lubrication assurance

In order to provide the proper lubrication quantity, the appropriate mounting position order code must be specified at the time of order. No unit will be shipped without the mounting position specified by the customer. The internal lubrication pathways are designed to:

- Bathe critical components regardless of horizontal position

- Prevent oil starvation (a common cause of failures in competitor units)

- Eliminate the need for extra fill ports or breather kits

Your reliability team will immediately appreciate the built‑in peace of mind.

3. Intelligent seal design that prevents leaks

Seals are often the first point of failure when gearboxes are mounted “incorrectly.” STOBER combats this with robust:

- Multi‑lip seals

- Optimized seal placement

- Tight machining tolerances

So even if installers aren’t perfectly level (because real-world equipment rarely is), leak risk stays low.

4. Zero extra hardware required

No special venting.

No aftermarket brackets.

No orientation‑specific field modifications.

Just install. Torque it down. Get back to production.

This “no-nonsense simplicity” is one of STOBER’s biggest advantages — and it’s why maintenance teams often say STOBER installations are the least stressful part of a rebuild.

Real-world example: A tight conveyor frame, zero mounting drama

Picture a food processor trying to squeeze a gearbox into a restrictive conveyor frame. Their previous supplier required a specific horizontal angle and a vent kit to avoid lubrication issues.

With STOBER? They mounted the unit at the angle that fit the frame — no special parts, no calls to engineering, no surprises at startup.

This kind of freedom reduces installation time and prevents common pitfalls that lead to downtime, warranty claims, and finger‑pointing between engineering and maintenance.

Why this matters for OEMs and maintenance teams

Choosing a gearbox that doesn’t care about horizontal orientation gives you:

✔ More design flexibility

Your engineers aren’t forced to redesign equipment just to accommodate gearbox limitations.

✔ Fewer installation mistakes

Even new team members can get it right the first time.

✔ Lower long-term maintenance risk

Improper mounting kills gearboxes. Removing complexity removes failure points.

✔ Faster changeovers and rebuilds

If you need to reposition the gearbox later, you can — without hunting for missing orientation manuals.

Make mounting simple. Choose STOBER.

When your equipment leaves no room for mounting guesswork, STOBER eliminates the drama. No vent kits. No orientation charts. No internal finger‑pointing. Just confidence, clarity, and ease — built directly into the gearbox.

If you’re tired of overcomplicated installations or limited mounting options, STOBER gives you the freedom to design and maintain equipment your way.

Ready to simplify your next build or rebuild?

Let’s talk about how STOBER can make mounting — and everything after — a whole lot easier.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

*Series-specific mounting position information is available in the free download documents which are located under the literature tab within each product section of our website.

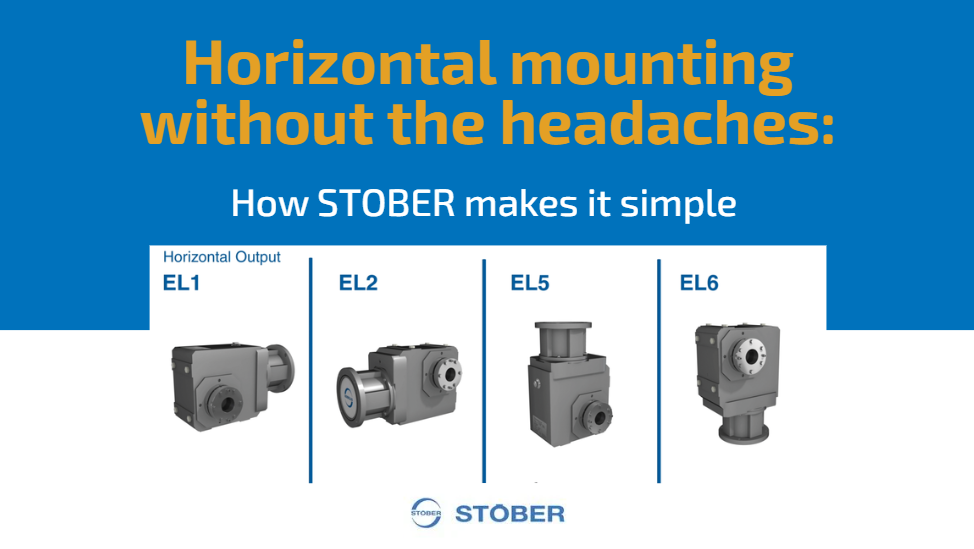

Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory