Excessive noise in industrial drive systems is rarely cosmetic. Most of the time, rising sound levels signal mechanical inefficiencies, developing wear, or operating conditions that fall outside design intent. Gearbox noise reduction focuses on identifying those root causes early on and correcting them before noise escalates into vibration, heat, and premature failure.

For mechanical engineers, facility managers, acoustic engineers, and environmental health and safety officers, controlling industrial gear noise supports safer workplaces, longer equipment life, and regulatory compliance. In this guide, we break down how gearbox noise develops and how it can be mitigated, helping teams improve reliability without unnecessary downtime.

Gearbox noise reduction basics: What “normal” sounds like vs. a problem

What counts as normal gearbox noise in industrial settings?

All gearboxes generate some sound during operation. Normal gearbox noise comes from predictable sources such as gear meshing, bearing rolling elements, motor electromagnetic excitation forces, and cooling airflow. In stable systems, these sounds remain consistent in level and frequency across normal operating speeds and loads.

From a diagnostic perspective, gearbox noise is a combination of airborne sound and structure-borne vibration. Most audible sound begins as internal vibration that travels through housings, shafts, mounts, and nearby structures before radiating into the surrounding environment.

Common noise categories and what they indicate

Different sound signatures point to different mechanical conditions:

- Whine: Often associated with gear mesh frequency, tooth profile deviations, or surface wear; a focus of targeted gear whine reduction

- Rumble or growl: Low-frequency noise commonly linked to bearing damage, shaft deflection, or load imbalance

- Knock or clatter: Impact-like sounds caused by excessive clearance, load reversals, or backlash noise

- Hiss: High-frequency noise related to lubrication starvation, aeration, or bearing cage instability

Sudden changes in sound character, new tonal components, or intermittent impacts usually indicate abnormal conditions rather than normal aging.

Why noise reduction matters beyond comfort

Noise is often an early symptom of declining mechanical efficiency. Rising sound levels frequently correlate with increased vibration, heat generation, and uneven load distribution across gear teeth and bearings. Addressing noise proactively often prevents secondary damage, reduces energy losses, and supports compliance with occupational noise exposure limits.

Gear mesh & tooth contact as core drivers of gearbox noise

Noise at the gear mesh starts when tooth engagement shifts from smooth rolling contact to uneven sliding or impact-driven contact. When load is evenly distributed and engagement occurs gradually, vibration remains low. But when that balance is disrupted, vibration increases and radiates as audible gear noise.

Effective gearbox noise reduction methods restore proper tooth engagement, verifying backlash, alignment, and load sharing before correcting surface damage interfering with rolling contact.

Mesh-related issues that increase noise

Several conditions are known to consistently raise noise levels:

- Profile or lead errors produce periodic tonal noise at mesh frequency

- Backlash that is too tight or too loose causes chatter or knocking, especially during reversals

- Surface distress such as micropitting or scuffing creates rough contact and broadband noise

- Changing wear patterns alter the contact ratio, amplifying harmonics over time

Inspecting the gear tooth contact pattern helps you confirm whether load is shared evenly across the tooth face.

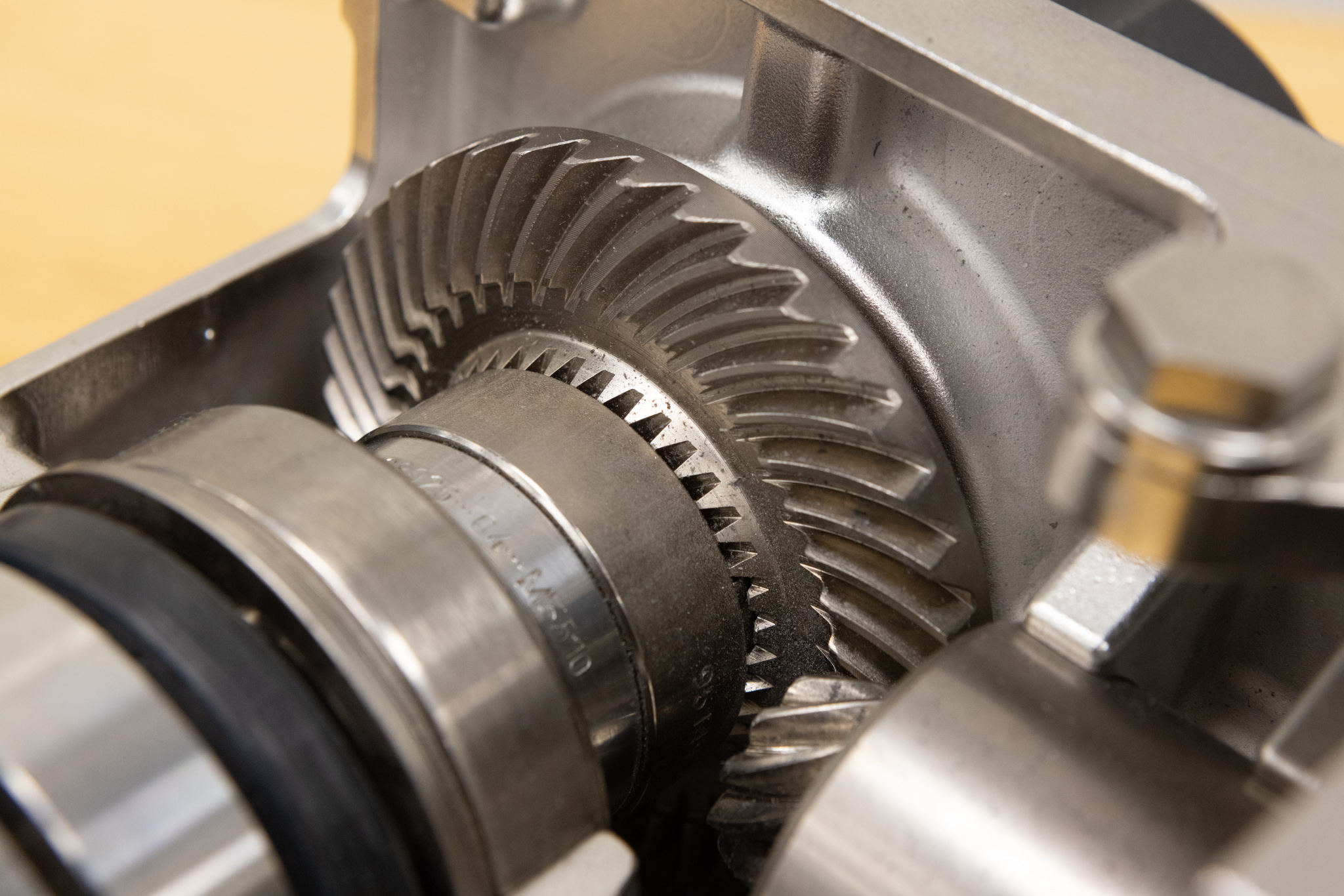

Gear type and geometry influence on noise

Gear geometry strongly affects baseline noise. Helical gears typically operate more quietly than spur gears because their angled teeth engage gradually and distribute load across multiple teeth; plus, a single helical gear tooth remains in contact longer, reducing impact forces. Planetary gearboxes can achieve low noise when load sharing is balanced but become noisy when tolerances degrade. Optimized gear design and surface finishing remain foundational to quiet gear drive design in demanding industrial applications.

Bearing, shaft, & alignment issues that amplify noise

Once bearings begin to degrade, they often dominate gearbox noise. Look out for common indicators like:

- Spalling or brinelling, producing a rumble that rises with speed

- Lubrication starvation or cage instability, generating high-frequency hiss

Bearing wear also amplifies vibration generated elsewhere in the gearbox, raising overall gearbox noise.

Alignment and shaft influences

Misalignment concentrates load on localized areas of gear teeth and bearings, increasing vibration and audible noise; typical misalignment noise symptoms include tonal noise that intensifies under load and uneven temperature patterns across housings. Overhung or excessive radial loads bend shafts, producing cyclic vibration that presents as low-frequency rumble and accelerates seal wear.

Diagnostic patterns help isolate causes: Noise strongest near input or output bearings often indicates bearing wear, while noise that rises with load rather than speed often points to alignment or loading issues.

Lubrication breakdown, contamination, & thermal effects on noise

A stable lubricant film acts as a natural damper. When film thickness collapses, metal contact increases, driving friction noise and vibration. Lubrication for noise control focuses on restoring and maintaining that film under operating conditions.

Correct oil viscosity selection is critical: Oil that thins excessively at temperature fails to separate surfaces, while oil that is too thick increases churning losses and noise.

Common lubrication-related noise causes

- Incorrect viscosity or additive selection leads to inadequate separation at operating temperature

- Underfilling pushes gears and bearings into boundary lubrication, rapidly increasing noise

- Overfilling or aeration introduces churning noise and heat buildup

Contaminants can easily accelerate noise development. Particles create abrasive contact that roughens gear teeth, while water contamination promotes corrosion and pitting that alters tooth engagement.

Thermal feedback loops

Heat and noise reinforce one another; increased friction raises temperature, thinning lubricant and further reducing film strength. Thermal monitoring and oil analysis often identify developing noise issues before they become audible.

Practical gearbox noise reduction actions: Design, setup, & maintenance

When noise increases, initial checks should focus on the fundamentals:

- Verify lubricant type, viscosity, and level

- Inspect mounting bolts, baseplates, and soft foot conditions

- Confirm coupling alignment

- Identify external resonance sources, including guards and acoustic enclosures for machinery

Often times, these steps will deliver measurable noise reduction without any major intervention.

Repair, re-selection, or redesign decisions

Noise tied to visible wear typically calls for repair or replacement. Persistent noise linked to operating conditions may indicate a mismatch between gearbox selection and application demands. In those cases, re-selecting a gearbox with an appropriate service factor or optimized geometry is often more effective than repeated repairs.

Recognizing signs it is time to replace your gearbox helps you prevent extended operation under damaging conditions. Ongoing inspections also help identify other signs you need industrial gearbox repair before failures escalate.

Long-term prevention strategies

Sustained noise control relies on predictive approaches. Condition monitoring for noise, including temperature trending and vibration analysis for gears, helps detect changes early. Combined with oil analysis, these tools support predictive maintenance for noisy gearboxes and reduce unplanned downtime. Over time, teams consistently find that maintenance is essential for controlling noise, especially in high-duty-cycle environments.

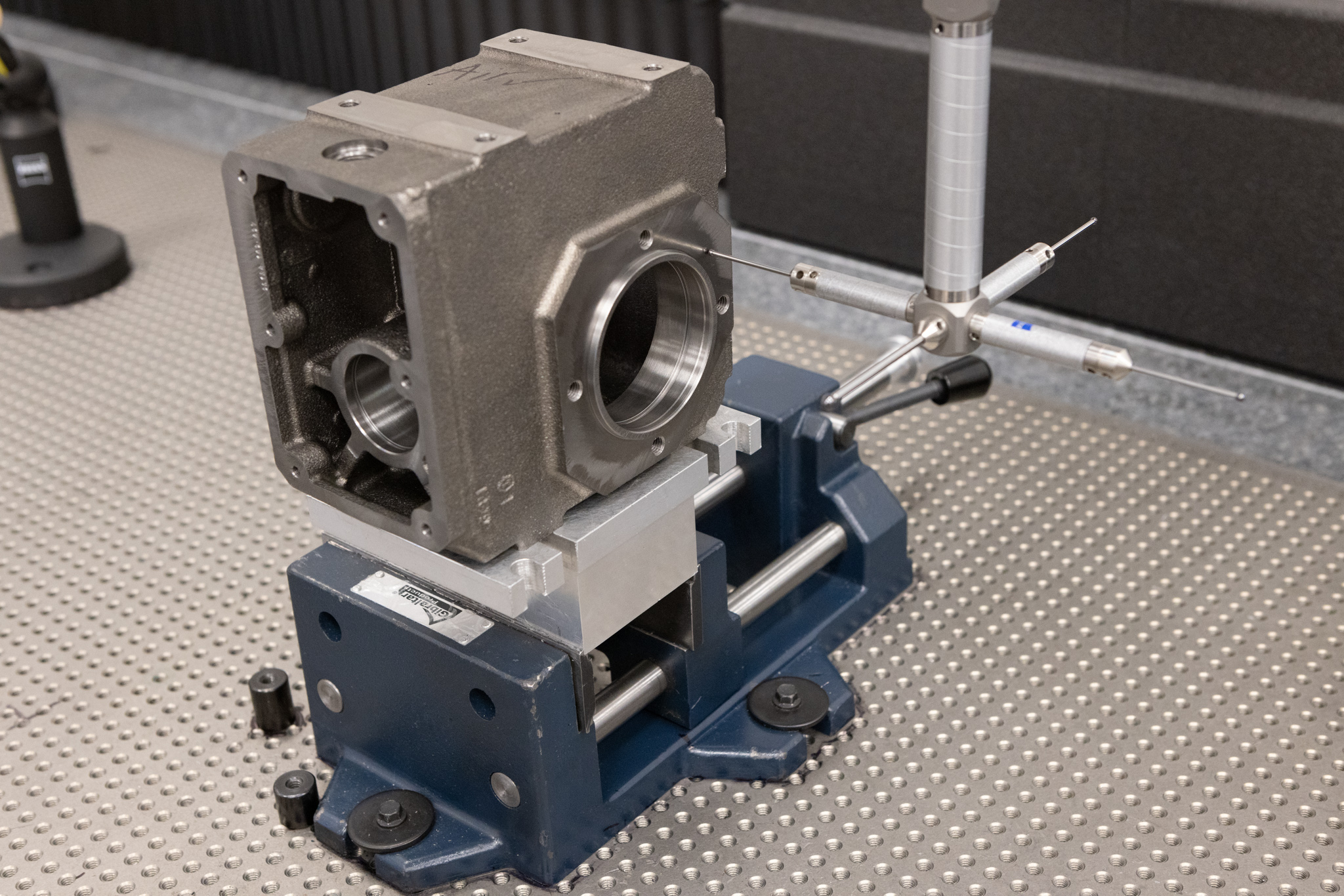

STOBER integrates noise control into gearbox and gear motor design through precision manufacturing, optimized tooth geometry, and robust bearing arrangements. Maintenance-free gearbox designs remove many lubrication-related failure modes, while tight tolerances reduce vibration transmission.

STOBER solutions are engineered for demanding applications with a nine-year mean time to failure and rapid availability through one-day build and ship capabilities. Tools like the STOBER Configurator support correct gearbox selection early in the design process, reducing the risk of noise caused by application mismatch.

In systems where motor noise contributes to overall sound levels, STOBER aftermarket services, including servo motor repair, help restore balanced operation across the entire drive system and address servo gearbox noise at its source.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

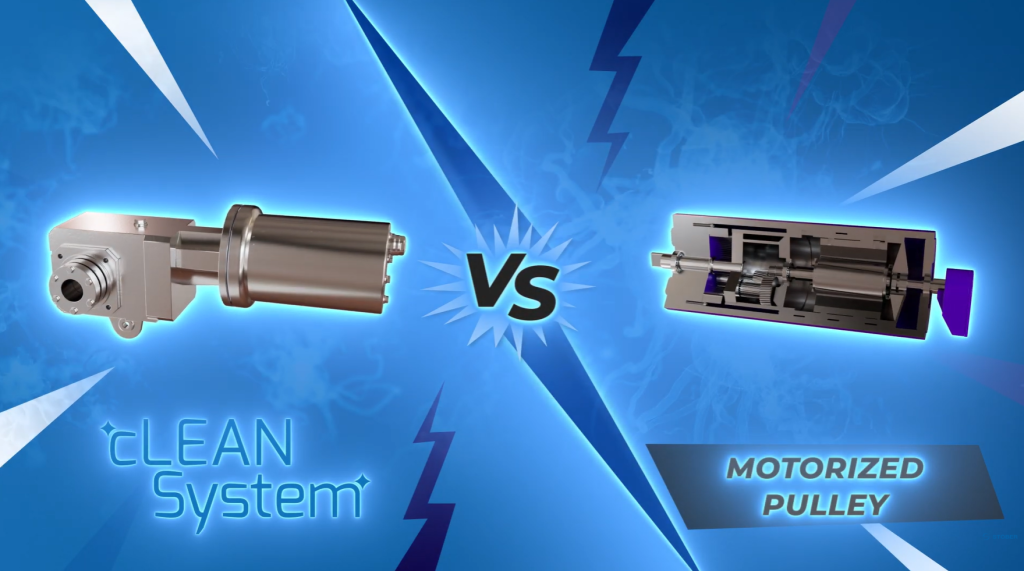

STOBER cLEAN System outperforms motorized pulley in food processing environments

STOBER cLEAN System outperforms motorized pulley in food processing environments  Ideal gearbox selection: Practical sizing checklist to save money

Ideal gearbox selection: Practical sizing checklist to save money  STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

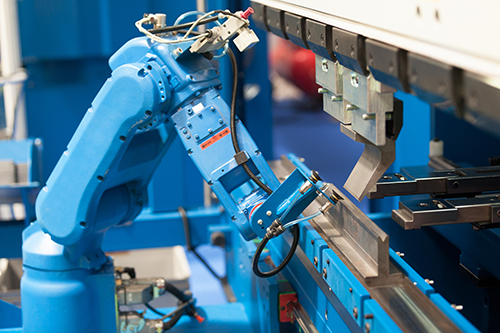

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

Selecting gearboxes for robotic & industrial automation systems