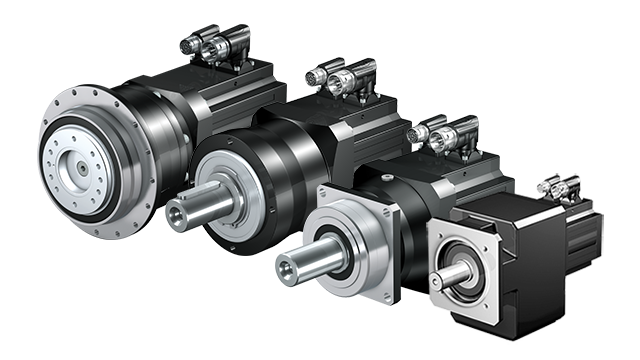

Synchronous Servo Inline Geared Motors

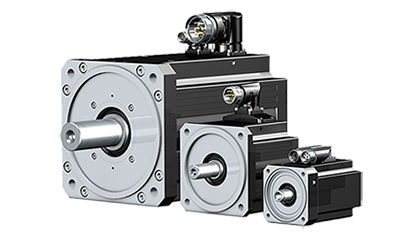

STOBER synchronous servo inline geared motors: The range you need.

These motors are available as planetary geared motors and as helical geared motors. Compact. Dynamic. Cooler. Adaptable. Packed with the STOBER guarantee – unparalleled service and support and an unmatched warranty of two years!

These motors are designed specifically to tackle some of the most rugged applications across multiple industries. They can be found in equipment used for aerospace manufacturing, automated production systems, beverage processing, printing operations and more. In addition to these standard models, we have the expertise and knowledge necessary to create fully customized solutions for your specific needs no matter what they may be.

We take pride in our ability to solve problems for our customers, creating the ideal solutions for their situations. Our experts work closely with you to identify your pain points and deliver a system that resolves them as thoroughly and effectively as possible.

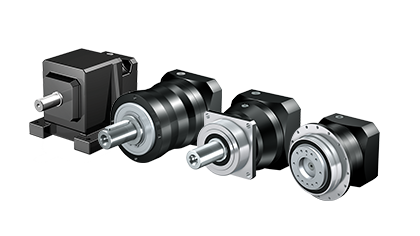

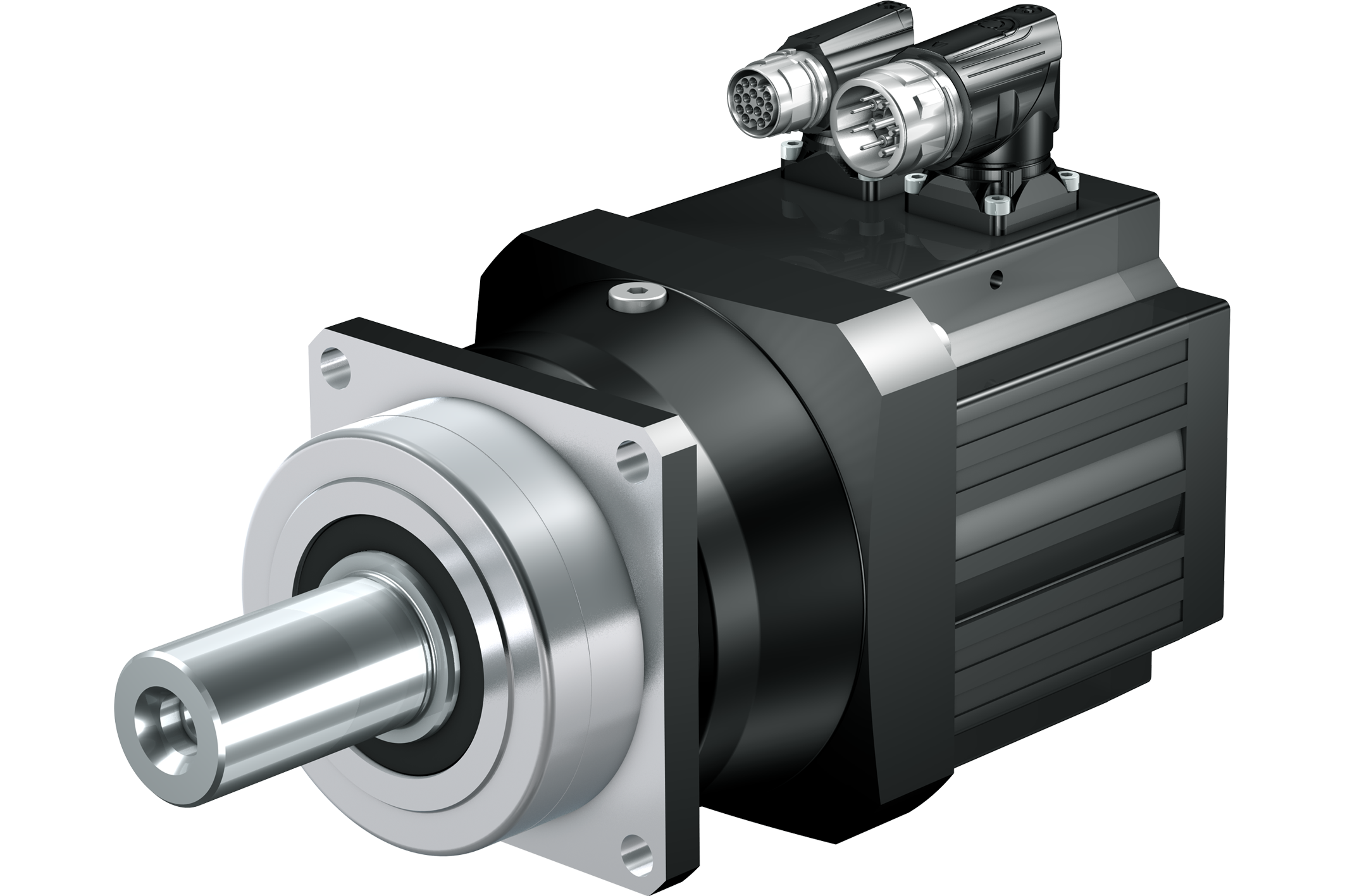

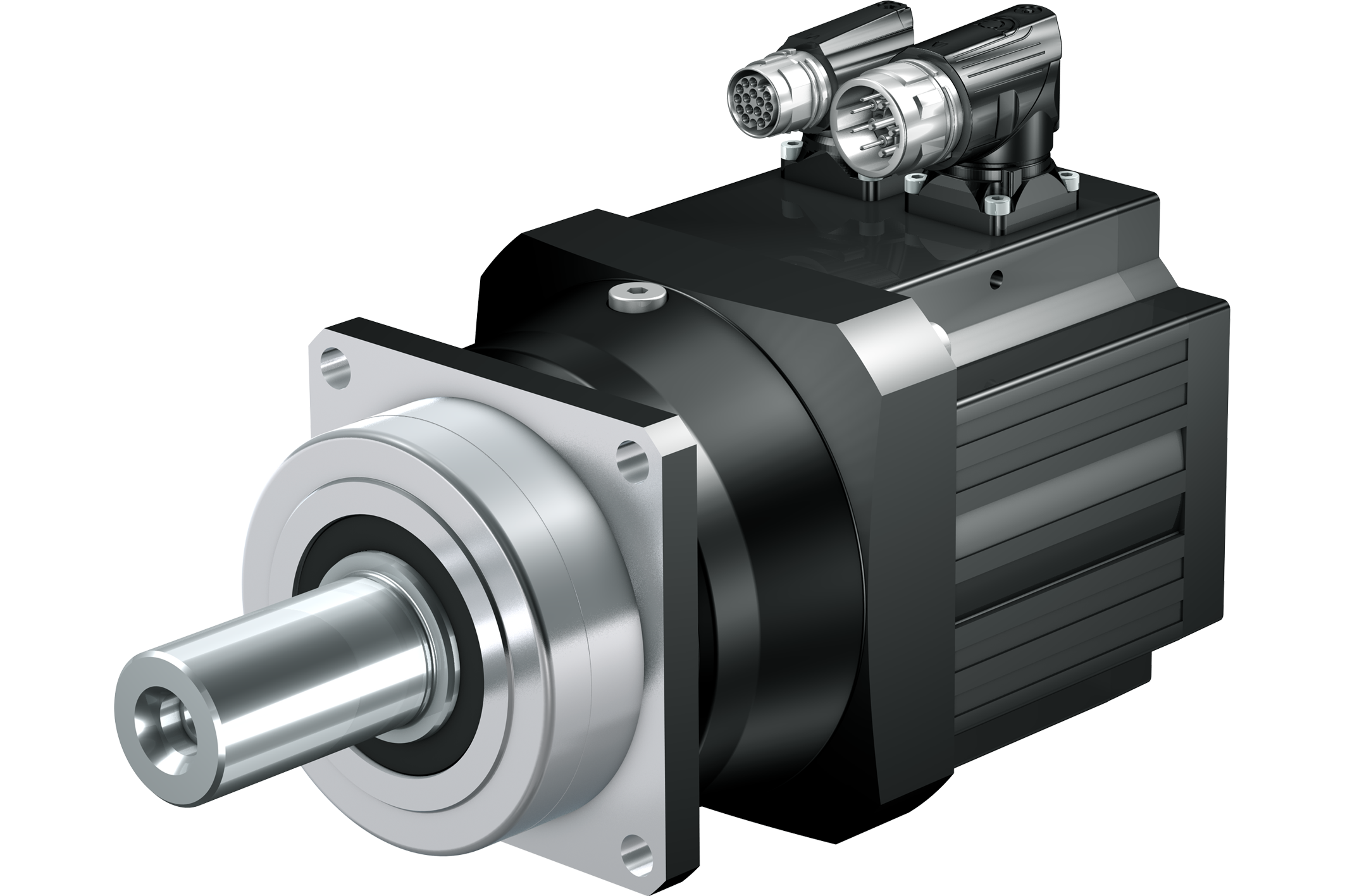

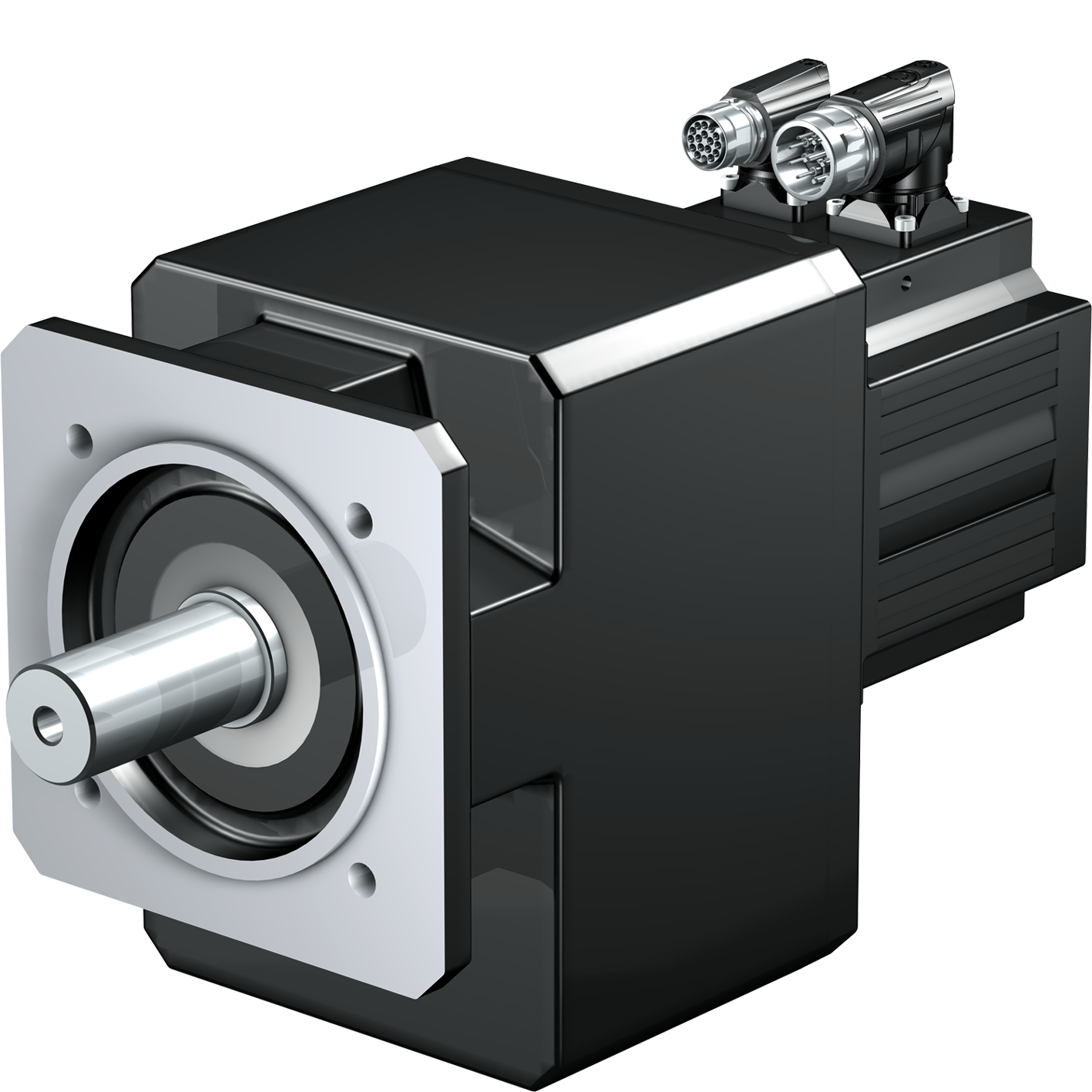

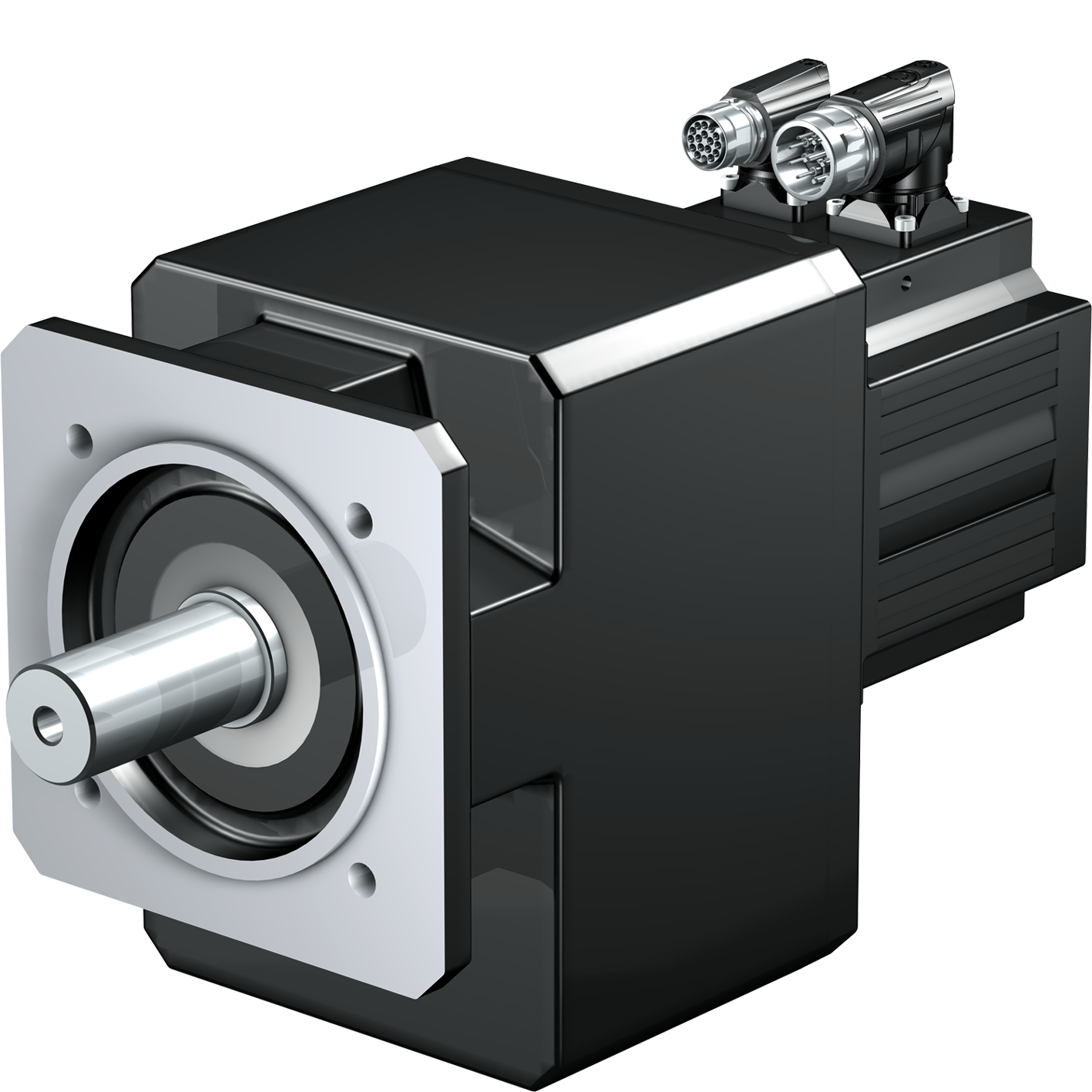

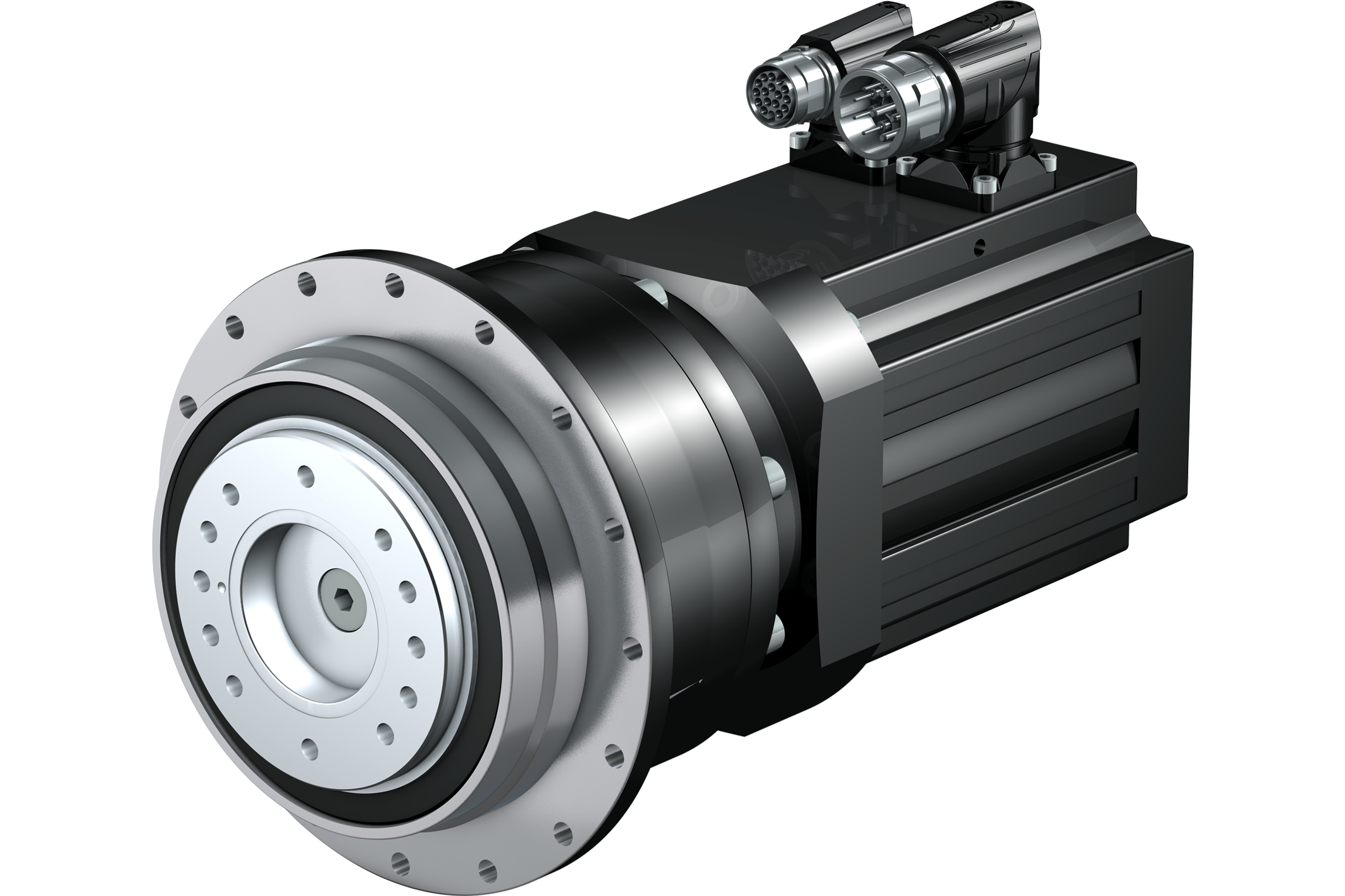

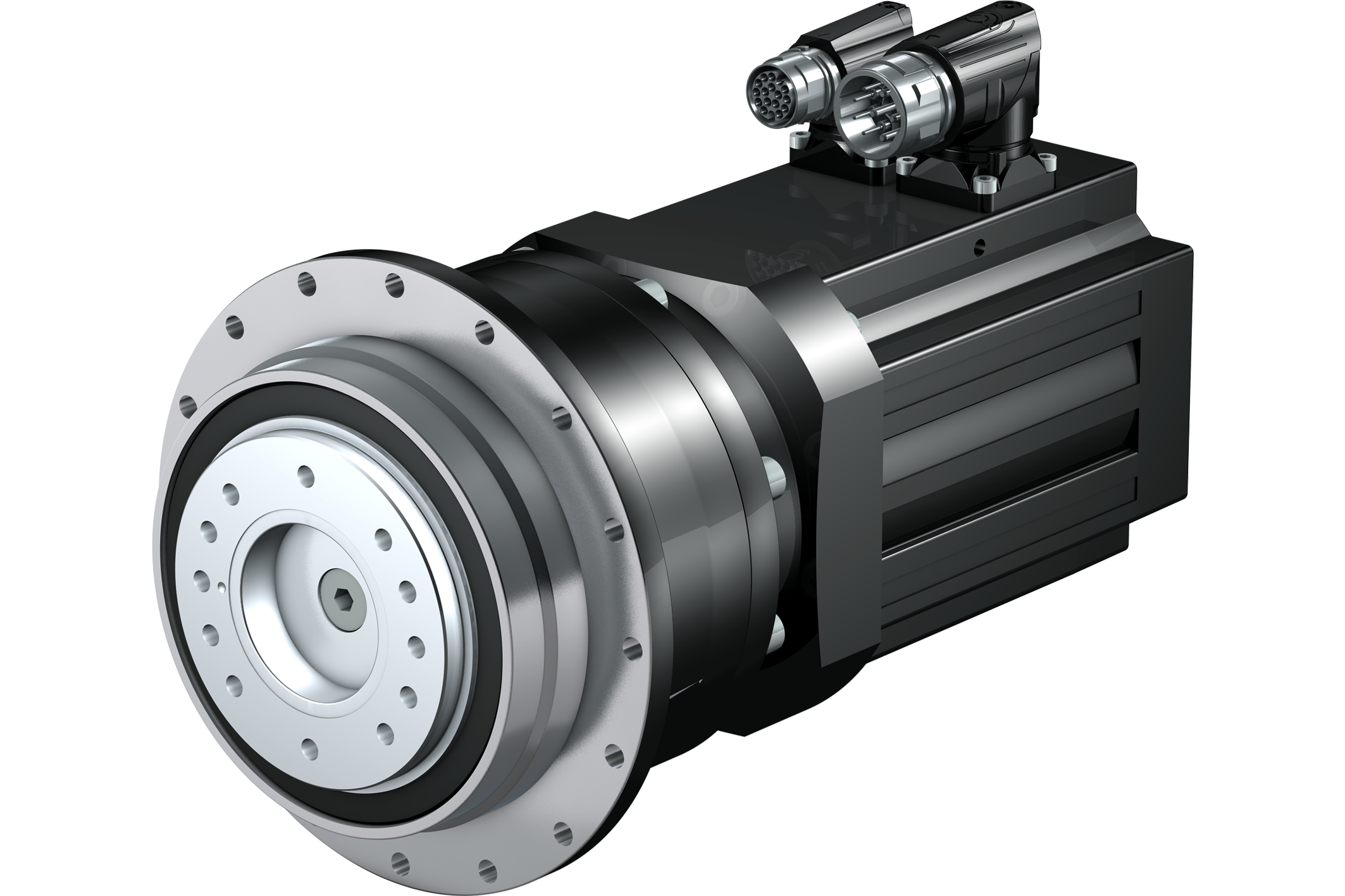

The P series features planetary gearing, providing unsurpassed smoothness and precision.

It is incredibly efficient, has low backlash, and runs quiet.

Plus, you can choose from several bearing options to handle radial or axial loads, optimizing your machine design.

When paired with our EZ motor, you benefit from optimal performance, compact design, and cool running.

P Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 100

- Acceleration torque: 11 – 3,450 Nm

- Nominal torque: 16 – 2,483 Nm

- Continuous Input Speed: Up to 6,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 407 Nm/arcmin

P Series: FEATURES

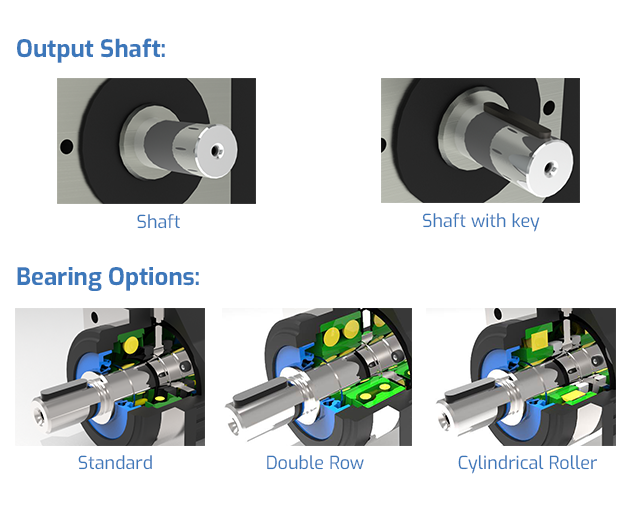

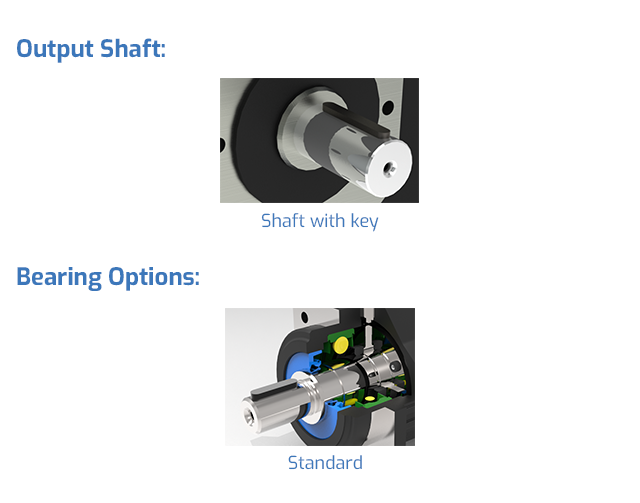

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty - 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- STOBER geared motor are fully supported with the drive manufacturers listed below. They are compatible with EnDat, Hiperface DSL, and Resolver.*

- Beckhoff

- Bosch

- B&R

- Control Techniques

- Kollmorgen

- Rockwell

- Siemens

* Note: Not all options are available for every drive.

- Brakes:

- Holding brake – ideal for vertical applications or maintaining position

- IP Ratings:

- 65 – standard

- 56

- 66

- Encoders:

- Hiperface DSL (Rockwell)

- EnDat

- Single-turn

- Multi-turn

- Optical

- Inductive

- 2.1

- 2.2

- Resolver

- Fan:

- Increase torque and cool system without upsizing to larger motor

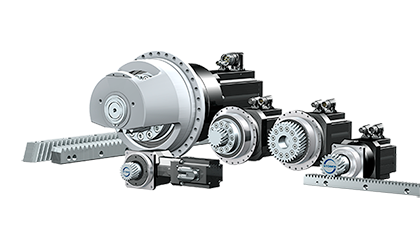

- Available as a rack and pinion system

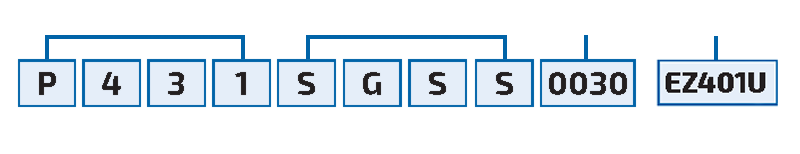

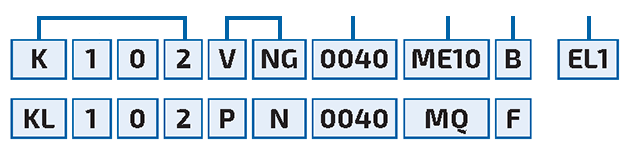

P Series: PART NUMBER EXAMPLE:

The C series utilizes helical gearing for up to 97% efficiency.

Choose the housing style that fits your application – round or square flanges, tapped holes, or foot mounting.

When paired with our EZ motor, you benefit from optimal performance, compact design, and cool running.

C Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 2 – 276

- Acceleration torque: 36 – 8,000 Nm

- Nominal torque: 35 – 7,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 393 Nm/arcmin

C Series: FEATURES

- Housing Styles:

- Round output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Square output flange

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- STOBER geared motor are fully supported with the drive manufacturers listed below. They are compatible with EnDat, Hiperface DSL, and Resolver.*

- Beckhoff

- Bosch

- B&R

- Control Techniques

- Kollmorgen

- Rockwell

- Siemens

* Note: Not all options are available for every drive.

- Brakes:

- Holding brake – ideal for vertical applications or maintaining position

- ServoStop – redundant safety brake

- IP Ratings:

- 65 – standard

- 56

- 66

- Encoders:

- Hiperface DSL (Rockwell)

- EnDat

- Single-turn

- Multi-turn

- Optical

- Inductive

- 2.1

- 2.2

- Resolver

- Fan:

- Increase torque and cool system without upsizing to larger motor

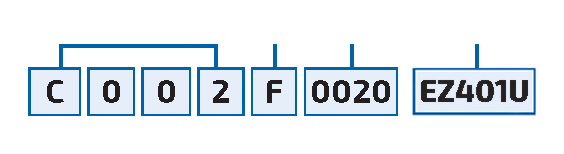

C Series: PART NUMBER EXAMPLE:

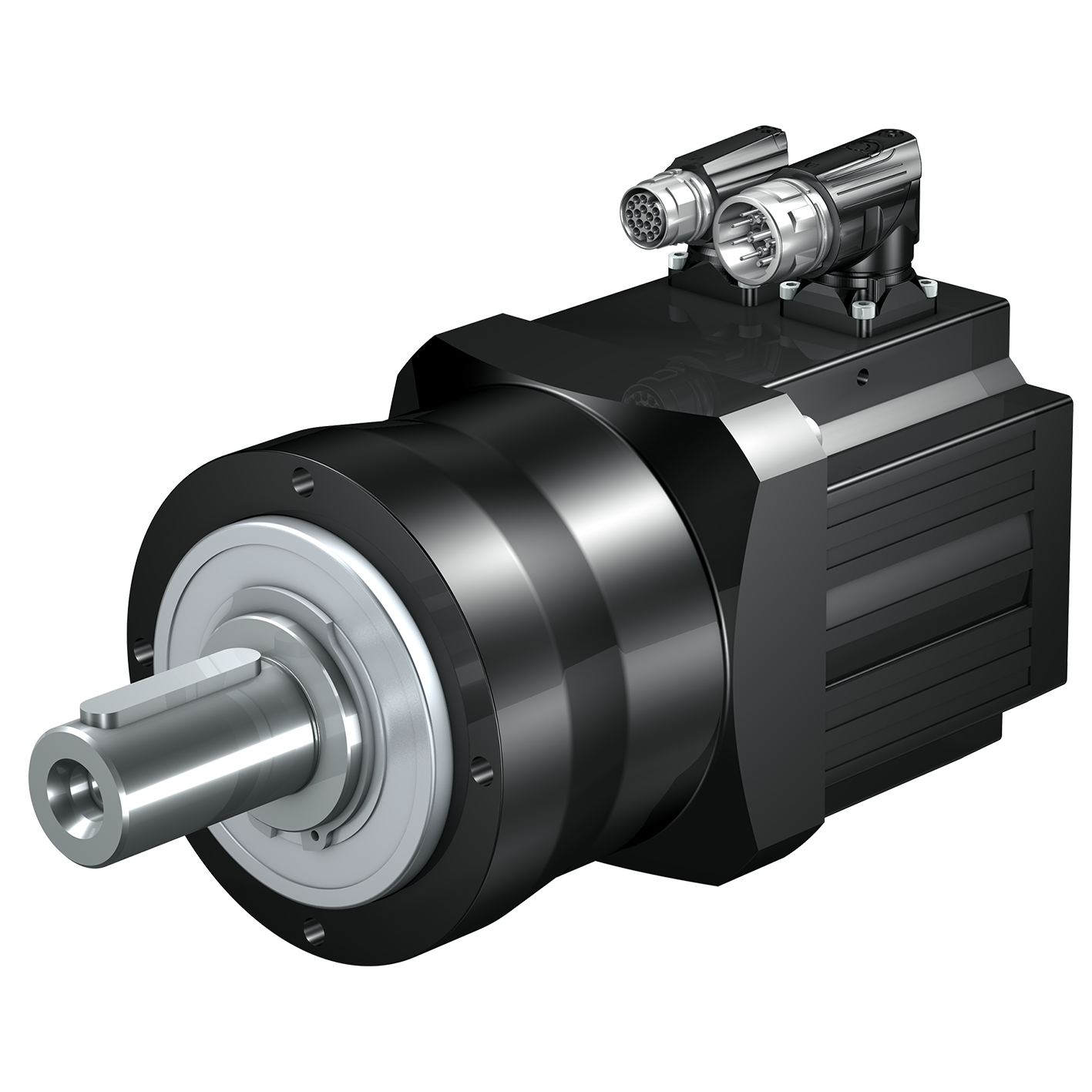

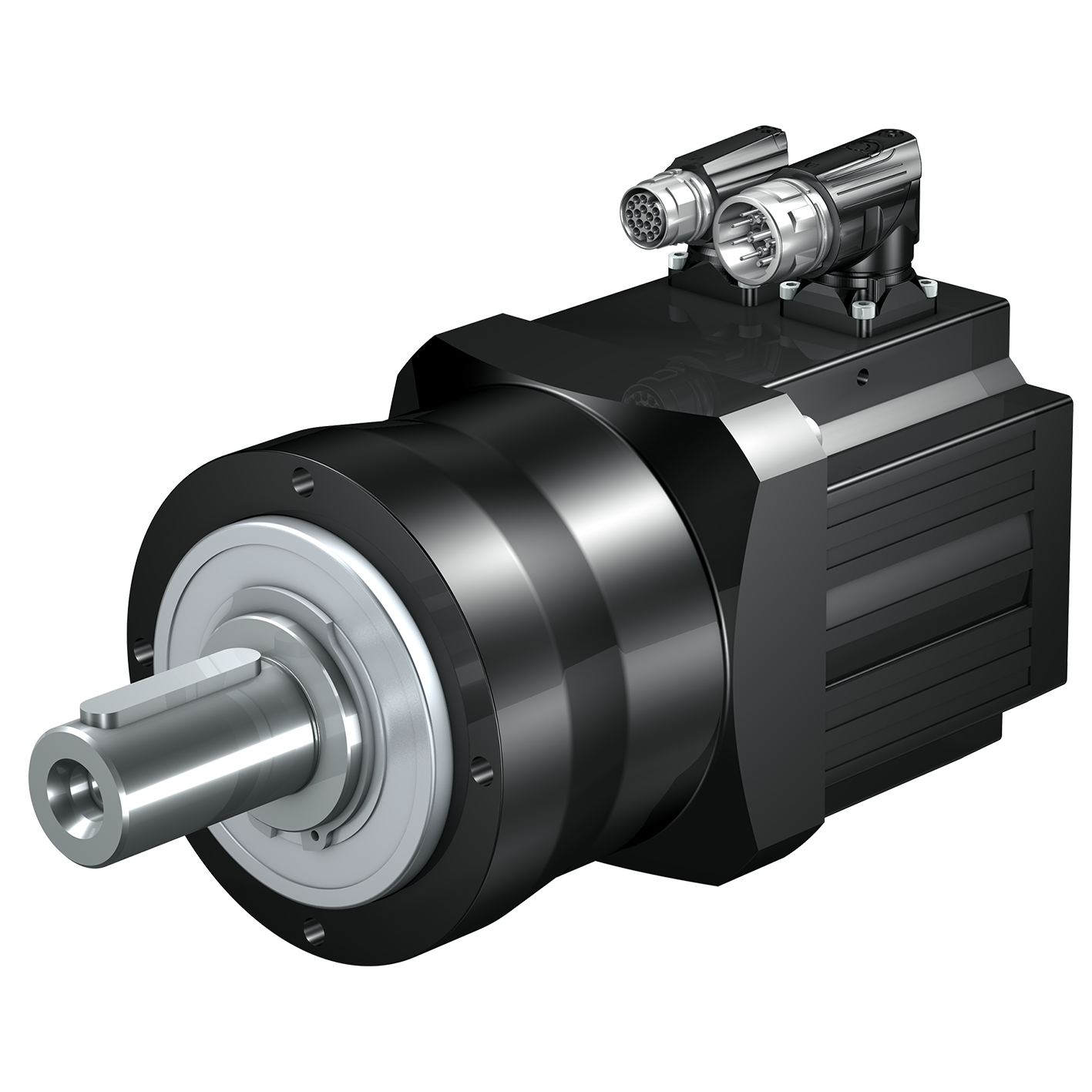

The PH series offers superior stiffness and accuracy.

It offers a reinforced bearing option for applications with higher axial loads.

When paired with our EZ motor, you benefit from optimal performance, compact design, and cool running.

PH Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 4 – 121

- Acceleration torque: 60 – 7,500 Nm

- Nominal torque: 36 – 5,000 Nm

- Continuous Input Speed: Up to 6,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 1,743 Nm/arcmin

PH Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- STOBER geared motor are fully supported with the drive manufacturers listed below. They are compatible with EnDat, Hiperface DSL, and Resolver.*

- Beckhoff

- Bosch

- B&R

- Control Techniques

- Kollmorgen

- Rockwell

- Siemens

* Note: Not all options are available for every drive.

- Brakes:

- Holding brake – ideal for vertical applications or maintaining position

- ServoStop – redundant safety brake

- IP Ratings:

- 65 – standard

- 56

- 66

- Encoders:

- Hiperface DSL (Rockwell)

- EnDat

- Single-turn

- Multi-turn

- Optical

- Inductive

- 2.1

- 2.2

- Resolver

- Fan:

- Increase torque and cool system without upsizing to larger motor

- Available as a rack and pinion system

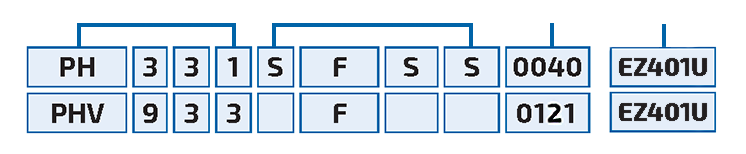

PH Geared Motors Series: PART NUMBER EXAMPLE:

The PE series is an attractive option for applications that don’t require the highest precision or smoothness.

Its unique for an economy option because it utilizes helical gearing.

When paired with our EZ motor, you benefit from optimal performance, compact design, and cool running.

PE Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 100

- Acceleration torque: 13 – 310 Nm

- Nominal torque: 7 – 160 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 35 Nm/arcmin

PE Series: FEATURES

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- STOBER geared motor are fully supported with the drive manufacturers listed below. They are compatible with EnDat, Hiperface DSL, and Resolver.*

- Beckhoff

- Bosch

- B&R

- Control Techniques

- Kollmorgen

- Rockwell

- Siemens

* Note: Not all options are available for every drive.

- Brakes:

- Holding brake – ideal for vertical applications or maintaining position

- IP Ratings:

- 65 – standard

- 56

- 66

- Encoders:

- Hiperface DSL (Rockwell)

- EnDat

- Single-turn

- Multi-turn

- Optical

- Inductive

- 2.1

- 2.2

- Resolver

- Fan:

- Increase torque and cool system without upsizing to larger motor

- Available as a rack and pinion system

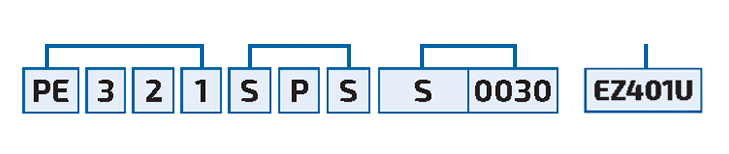

PE Geared Motors Series: PART NUMBER EXAMPLE:

The PHQ series features four planetary gears, making it the most powerful gearbox on the market.

It provides smooth operation while producing huge amounts of torque.

When paired with our EZ motor, you benefit from optimal performance, compact design, and cool running.

PHQ Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 5.5 – 600

- Acceleration torque: 200 – 43,000 Nm

- Nominal torque: 100 – 25,000 Nm

- Continuous Input Speed: Up to 4,500 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 6,269Nm/arcmin

PHQ Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- STOBER geared motor are fully supported with the drive manufacturers listed below. They are compatible with EnDat, Hiperface DSL, and Resolver.*

- Beckhoff

- Bosch

- B&R

- Control Techniques

- Kollmorgen

- Rockwell

- Siemens

* Note: Not all options are available for every drive.

- Brakes:

- Holding brake – ideal for vertical applications or maintaining position

- ServoStop – redundant safety brake

- IP Ratings:

- 65 – standard

- 56

- 66

- Encoders:

- Hiperface DSL (Rockwell)

- EnDat

- Single-turn

- Multi-turn

- Optical

- Inductive

- 2.1

- 2.2

- Resolver

- Fan:

- Increase torque and cool system without upsizing to larger motor

- Available as a rack and pinion system

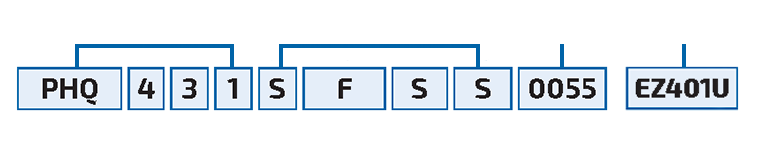

PHQ Geared Motors Series: PART NUMBER EXAMPLE:

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Catalog Synchronous servo geared motors EZ | 15 | 442437 | 2025 05 | EN | 25.03 MB |