An industrial gearbox is an enclosed system designed to transfer torque and control speed across machines used in demanding environments. These components are central to heavy-duty and precision applications, ensuring that mechanical power is transmitted efficiently, safely, and consistently. From mining operations to robotics, gearboxes help keep equipment in motion.

There are several different types of gearboxes, each with a unique design and industrial application. Selecting the right configuration can lead to measurable cost savings, improved reliability, and reduced downtime. Misaligned selection, however, can result in inefficiencies, higher maintenance demands, or even premature equipment failure.

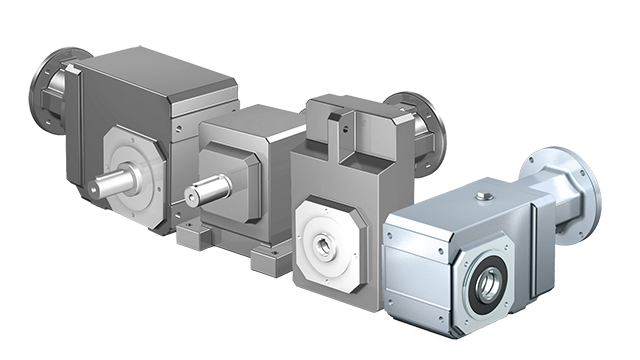

As a trusted gearbox manufacturer, STOBER has built a reputation for delivering high-precision solutions across industries such as food and beverage, automation, and material handling. Choosing the right gearbox type has benefits beyond performance, also supporting compliance, productivity, and lifecycle value.

Spur gearboxes for industrial power transmission

Spur gearboxes are among the simplest and most widely used industrial gearbox types. Their straight-tooth design allows efficient power transfer between parallel shafts, making them highly efficient and durable while keeping manufacturing costs relatively low.

Spur gearboxes excel in applications where cost-effectiveness and reliability are more important than noise reduction. They’re easy to maintain, predictable in performance, and remain a standard in conveyors, low- to medium-speed machinery, and packaging systems. They’re frequently used as reduction gearboxes, as their role is to lower speed while increasing torque for straightforward power transmission needs.

Limitations include higher noise and vibration levels at elevated speeds, as the straight-tooth design results in sudden tooth engagement. Compared with helical or bevel gearboxes, spur gearboxes are less smooth and have lower load-carrying capacity. Maintenance technicians benefit from longer intervals between service, which reduces unplanned downtime and lowers lifecycle costs.

Maintenance technicians benefit from longer intervals between service, which reduces unplanned downtime and lowers lifecycle costs.

Helical gearboxes for smooth & heavy-duty operations

Unlike spur designs, helical gearboxes use angled teeth, enabling multiple contact points that result in smoother, quieter operation. This design feature also increases torque capacity and efficiency, especially at higher speeds.

Helical gearboxes are available in multiple configurations to match specific industrial needs. A right-angle helical gearbox is often used in conveyors and mixers where space is limited but torque demands are high. An inline helical gearbox or coaxial helical inline gearbox is ideal for applications requiring compactness, smooth power delivery, and easy integration with motors. Variations highlight how engineers can choose a helical design that balances load, space, and performance.

Because of their durability and smooth operation, helical gearboxes are widely used in manufacturing, material handling, and process automation systems. Their ability to reduce backlash means fewer unexpected breakdowns, a top concern for operations managers focused on uptime.

STOBER helical gearboxes are engineered with precise alignment, minimizing backlash and ensuring torque is consistently delivered under demanding conditions. This gives engineers and product designers confidence when specifying gearboxes for high-load environments.

Bevel gearboxes for angular power transmission

Bevel gearboxes are used where angular power transmission is required. Their cone-shaped gears transfer power between intersecting shafts, typically at 90 degrees. This makes them compact and efficient for applications needing directional change in confined spaces.

Variations of bevel gearboxes are common; straight bevel gear designs are used for simpler angular power needs, while helical bevel gearboxes and skew bevel helical gearbox models provide smoother operation and higher torque transfer in more demanding systems.

Bevel gearboxes are commonly found in mining, quarries, steelworks, and automation systems. Their ability to handle angular loads makes them valuable in conveyor junctions, cranes, and power transmission systems. While more expensive than spur gearboxes, they offer greater precision for specific angular applications.

One trade-off is torque capacity, which is generally lower than that of parallel-shaft alternatives. They also require careful lubrication and maintenance to avoid premature wear due to angled tooth contact. Engineers must weigh these factors carefully when planning long-term reliability.

Worm gearboxes for high torque reduction

Worm gearboxes feature a worm-and-wheel design that delivers high reduction ratios in a compact footprint. This configuration provides a unique advantage: worm gearboxes are non-backdrivable, which prevents reverse motion and enhances safety in applications like lifts, conveyors, and hoists.

Their advantages include high torque reduction and built-in safety features, making them invaluable for equipment where sudden back-driving could be dangerous. Industries such as elevators, packaging, conveyors, and material handling rely on worm gearboxes for their ability to deliver torque securely and consistently.

On the downside, worm gearboxes have lower efficiency due to sliding contact between the worm and wheel. This generates heat, requiring proper lubrication and cooling strategies. Left unchecked, inefficiency and heat buildup can shorten lifespan.

Compared to helical bevel gearboxes, worm gears typically offer less torque for their size, which can often be a drawback in space-constrained designs. Worm gear designs generally have more backlash and less repeatable position than precision gearboxes like servo helical bevel types. At higher speeds, the efficiency of worm gearboxes drops and heat issues become more pronounced.

Planetary gearboxes for high torque & compact design

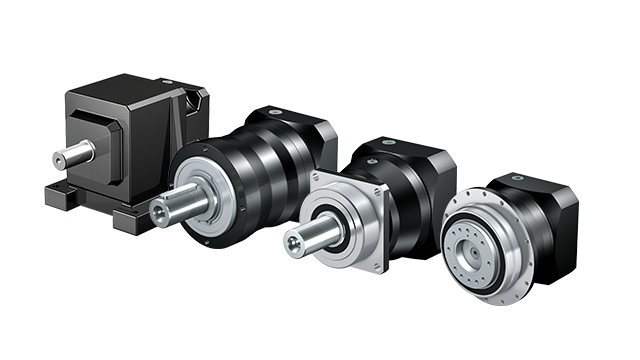

Planetary gearboxes use a sun gear, planet gears, and a ring gear to evenly distribute load. This unique structure results in very high torque density, a compact design, and minimal backlash — all while maintaining efficiency above 90%.

Industries such as robotics, aerospace, renewable energy, and automated packaging rely heavily on planetary gearboxes for their compact footprint and precision. They’re often selected when engineers need compact industrial gearboxes that can deliver exceptional torque without consuming excessive space.

Modularity makes planetary gearboxes versatile, as they can be combined with other gearbox stages to achieve customized ratios. STOBER offers custom industrial gearboxes for applications requiring non-standard ratios or special performance requirements, ensuring engineers don’t have to compromise between size, efficiency, and durability.

STOBER planetary gearboxes are designed for integration with servo motors and automation equipment. Their precision and flexibility support product designers looking to push performance while maintaining compact designs.

Comparing industrial gearbox types & selection criteria

Each of the five industrial gearbox types offers distinct advantages and trade-offs:

- Spur: Simple, cost-effective, efficient, but noisier.

- Helical: Smooth, high load capacity, quieter, versatile.

- Bevel: Angular drive, compact, higher cost, lower torque.

- Worm: High torque reduction, safety, lower efficiency, shorter lifespan.

- Planetary: Compact, precise, high torque density, efficient.

When evaluating gearbox selection, engineers must consider torque requirements, load capacity, space constraints, and operating conditions such as duty cycle and temperature. Efficiency and lubrication strategy also play critical roles in long-term reliability.

Noise reduction techniques, such as using helical gears or advanced materials, can significantly affect gearbox choice. Modern gearbox design software now allows engineers to simulate load conditions and predict maintenance needs before deployment.

For maintenance managers, a proper gearbox maintenance checklist — including lubrication, vibration monitoring, and thermal imaging — is essential to prevent failures. STOBER supports customers with guidance that combines real-world application data and expert engineering insight.

Why choose STOBER for industrial gearboxes?

STOBER stands out as a reliable partner for industrial gearbox types across the board. Our gearboxes are engineered with precision for long service life and modular design flexibility. Built and shipped in just one day from Maysville, KY, STOBER ensures quick delivery without sacrificing quality.

Our product range includes right-angle, inline, planetary, rack and pinion, and stainless steel washdown gearboxes — all designed for lifecycle value. With reduced downtime, no oil changes required, and robust service support, STOBER helps maintenance managers and operations teams avoid costly interruptions.

Explore STOBER products for applications across many industries, and contact STOBER to discuss solutions that improve reliability, efficiency, and long-term performance.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025