If gearboxes fail, production stops.

Predictive and preventative gearbox maintenance helps reduce the risk of unexpected failures and increase the usable lifespan of industrial gearboxes and gearbox components.

In this blog, we’ll explore the why, how, what, and when of gearbox maintenance, and offer actionable insight to help your team maximize gearbox performance.

Why gearbox maintenance matters in industrial settings

Gearboxes are translators. They translate the power supplied by motors and alter the speed, direction, and torque to match the requirements of individual machines.

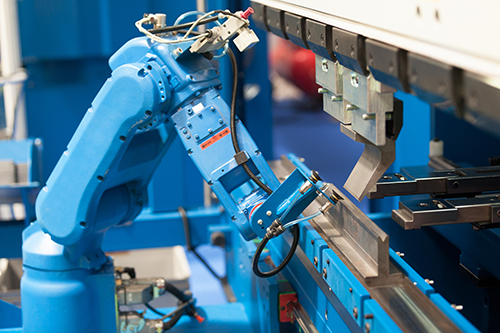

Gearboxes are central to motion control and power transmission systems in sectors such as automated manufacturing, product or parts conveying, packaging, and component assembly.

Unexpected failure of gearboxes can lead to serious consequences. In the best-case scenario, failures are caught early, resulting in downtime and lost revenue while repairs are carried out. In the worst case, gearbox failure leads to catastrophic machine failure, damaging other equipment and putting staff at risk.

Preventive maintenance helps reduce the risk of unscheduled shutdowns by identifying issues before they become critical. Regular maintenance is often more cost-effective than repairs or replacements, especially if your company relies on high-precision or customized gear systems.

Core components to monitor in a gearbox maintenance program

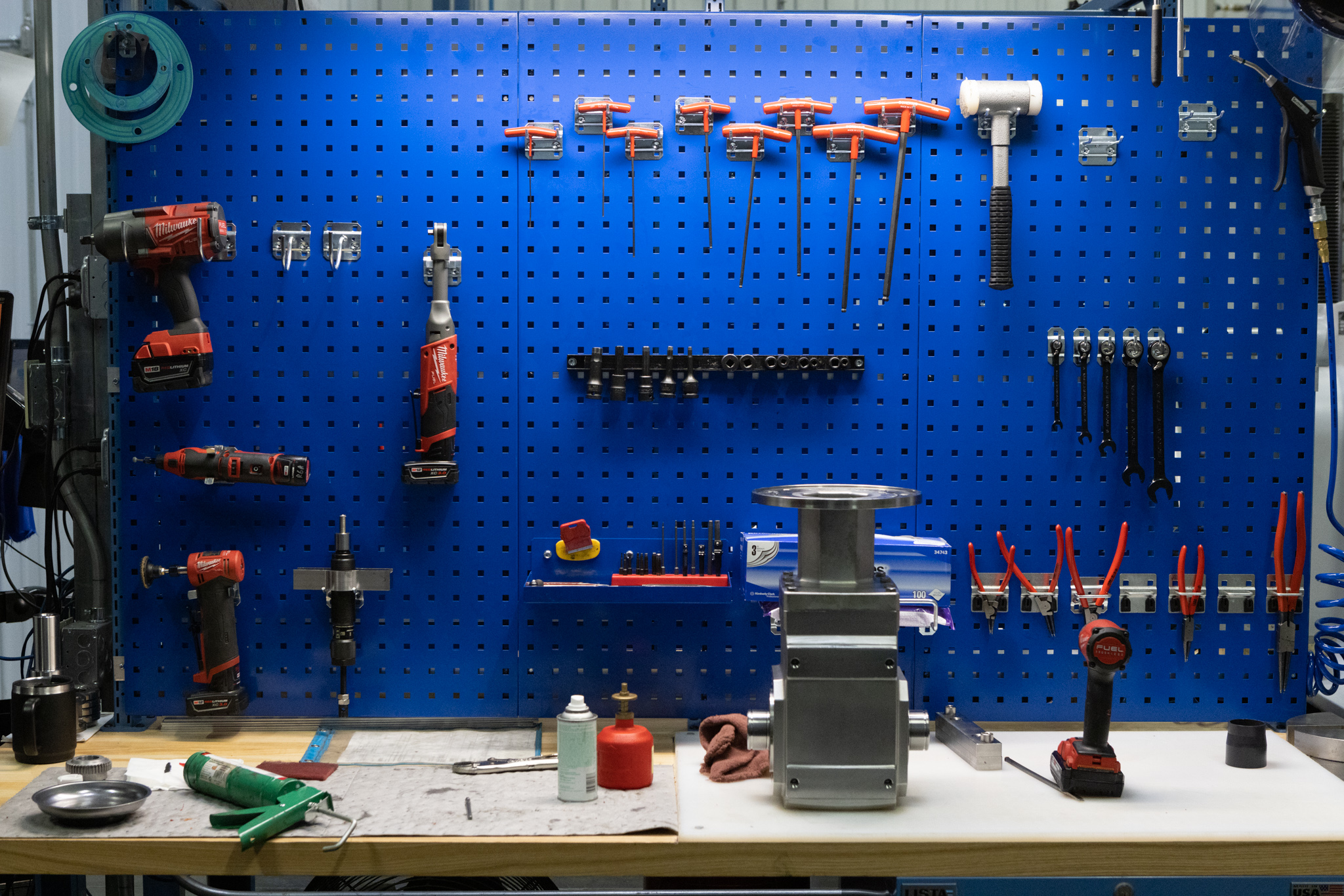

Creating a routine inspection and servicing program can help reduce the risk of unexpected gearbox failures.

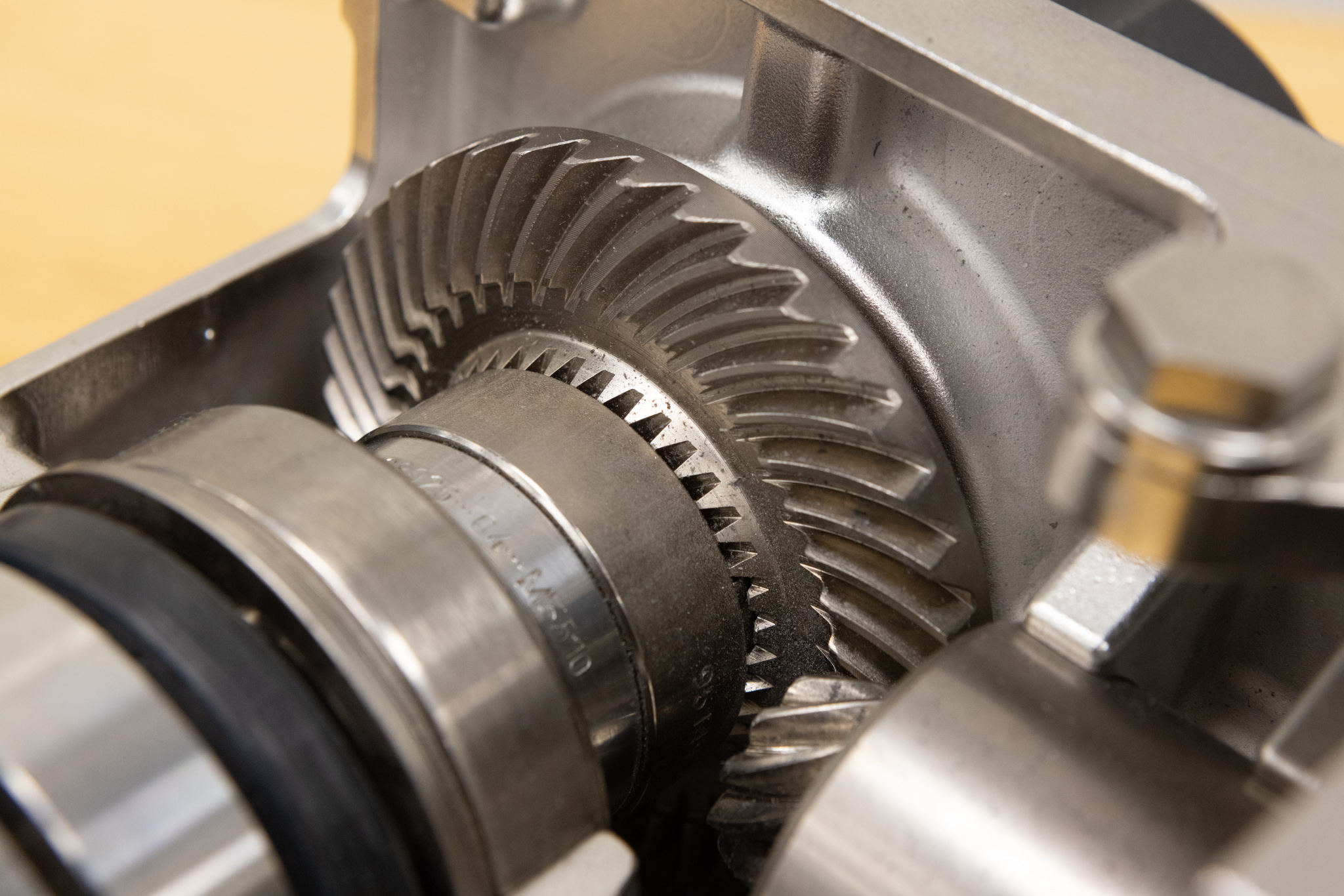

These inspections should consist of both visual and hands-on inspections. Along with obvious issues such as misalignment or cracking, maintenance teams should also identify patterns of wear and tear — different patterns may indicate potential failure points. Consider spalling, the detachment of surface material from gear teeth. If multiple inspections reveal that spalling is concentrated on a single gear or set of gears, this indicates a wear pattern to watch.

Core components to check during gearbox repair and maintenance include:

- Lubrication systems — Oil levels, viscosity, temperature, and contamination all play a critical role in heat dissipation and friction control. Low oil levels combined with increased viscosity can lead to spikes in temperature. Add in debris such as dirt or water, and the chances of failure significantly increase. Proper lubrication is essential for continued operations.

- Seals and breathers — Cracking, splitting, or discoloration on seals and breathers can lead to fluid leaks, which cause internal gearbox damage.

- Bearings and shafts — Both endplay and vibration are early signs of internal wear and tear or misalignment. This is because any additional axial movement creates an imbalance in gearbox systems, which can lead to failure.

- Gear teeth — Macropitting, spalling, misalignment, and repeated wear patterns on gear teeth may indicate bearing or load issues that can cause failure if left unchecked.

- Casing and mounting — As part of regular visual checks, teams should look for cracks, discoloration, and insecure fitment in casings and mountings. Any of these signs could indicate temperature or pressure issues that require parts replacement.

- Alignment and backlash — Gear misalignment can lead to friction, heat, and damage. Backlash — the gap between gear teeth when the operational direction is reversed — is also problematic. All gears have some degree of backlash, but if backlash is increasing over time, it may indicate an underlying issue with lubrication or fit.

Lubrication best practices for gearbox longevity

Lubrication is the core of gearbox performance. Minimal or missing lubrication creates friction, which in turn creates heat. In combination, friction and heat can reduce performance, accelerate wear and tear, and significantly increase the chance of equipment failure.

Here are four gearbox maintenance tips to improve longevity:

- Follow manufacturer recommendations: Always follow manufacturer recommendations for lubricant type, ideal viscosity, and potential additives.

- Understand the impact of temperature: Temperature impacts lubricant degradation. Temperatures greater than 150 degrees Fahrenheit shorten oil life, while temperatures over 180 F require more frequent changes.

- Carry out routine sampling and analysis: Routine sampling and analysis of oxidation, sludge, and other contaminants are more effective than reacting to symptoms after they appear.

- Consider circulating lubricant systems: For high-hear applications, circulating lubricant systems or low oil level designs can reduce the risk of overheating and minimize seal damage.

Signs of gearbox distress & early failure indicators

The earlier you detect and identify gearbox problems, the less damage systems incur and the more time you have to fix these issues.

In many cases, simple checks of operating conditions combined with the right tools can prevent catastrophic failures. Simple checks fall into three categories: visual, audible, and mechanical. Visible signs of distress include discolored paint, leaking seals, and excessive dust accumulation. Audible signs may be changes in gear noise or unusual vibrations, while increased backlash, abnormal shaft play, and elevated operating temperature may indicate mechanical failure. Gearbox noise diagnosis can help pinpoint potential problems.

Common tools for failure detection include infrared thermometers, vibration analysis sensors, endoscopes, and dial indicators. The right tool for the job also depends on environmental conditions. For example, in high-noise environments, vibration monitoring is often more effective than sound-based diagnostics.

Establishing a preventive gearbox maintenance routine

Preventive maintenance doesn’t happen by accident. Occasional checks and random inspections will detect some issues, but won’t provide the context needed to take effective action.

To maximize maintenance effectiveness, it’s critical to create and implement a preventative industrial gearbox upkeep routine. Key components of this routine include:

- Always reference baseline guidance: Start with the basics. Carry out your first oil change after 500 hours, then every 2,500 hours or 6 months per AGMA. Worth noting? Some gearboxes may not require oil changes — advancements in gearing, housing design, component materials, and assembly processes have resulted in cutting-edge solutions that are virtually maintenance-free.

- Combine condition monitoring with calendar-based checks: While calendar-based checks reduce failure risks, it’s also worth carrying out regular condition monitoring. In practice, this means making visual checks part of everyday operations. For example, when employees start or end their shifts, they can carry out a quick visual inspection. If they notice something odd about machine behavior, their first step should be an inspection. By creating a gearbox lubrication schedule and combining this with event-driven observations, failure risk is reduced.

- Track inspections with logs and compare them to baseline measurements: Every inspection should be tracked and logged. This allows you to compare current measurements to baseline values and create a gearbox inspection checklist that targets common concerns.

- Identify escalation criteria: When does observation turn into action? By identifying escalation criteria, companies can balance the need for repair against the costs of maintenance. For example, if employees see signs of gearbox wear, they can log this data and keep working. If they identify significant friction or temperature issues, meanwhile, they can refer the issue to proper maintenance teams.

- Consider outside specialists: While it’s possible to handle all industrial gearbox maintenance in-house, it’s often worth partnering with machinery and engineering experts for complex systems, customized components or critical uptime applications.

From maintenance to optimization — designing for serviceability

Gearbox maintenance is essential for continued functionality. Gearbox optimization can help reduce downtime, improve performance and increase usable life spans.

To move from maintenance to optimization, companies need modular, service-friendly gear units and servo motor solutions combined with scheduled evaluations and proactive gearbox cleaning procedures.

Not sure how to extend gearbox life while ensuring stable production cycles? STOBER can help your organization streamline gearbox maintenance to improve issue detection, reduce downtime risks, and increase equipment lifespans. Get in touch today.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

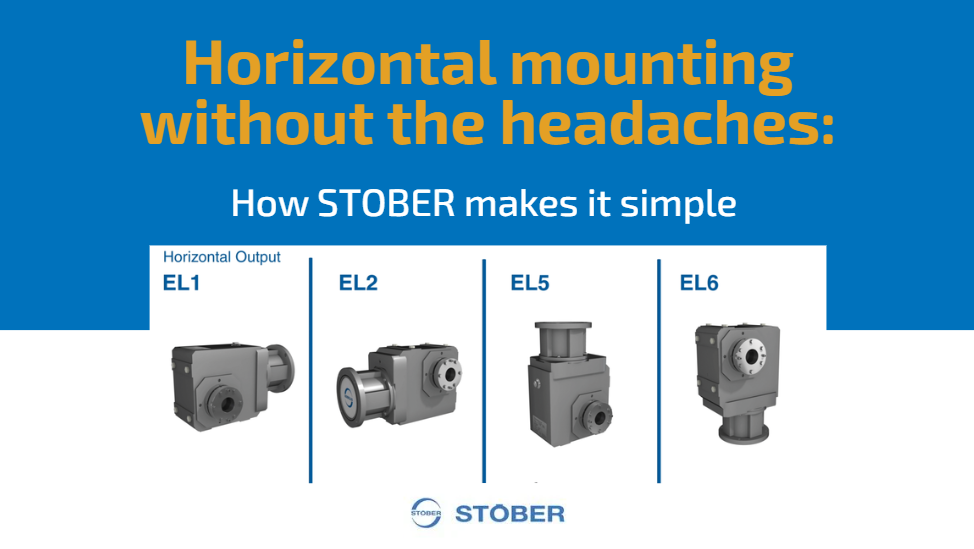

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs