A leading poultry processor in the mid-Atlantic was facing repeated failures and costly downtime on a critical section of its production line. Uptime was being halted by gearboxes on their conveyor systems that couldn’t withstand the demands of washdown conditions, high torque requirements, and continuous operation. Frequent breakdowns led to production delays, increased maintenance costs, and pressure on plant performance.

They knew it was time to call STOBER.

The STOBER solution

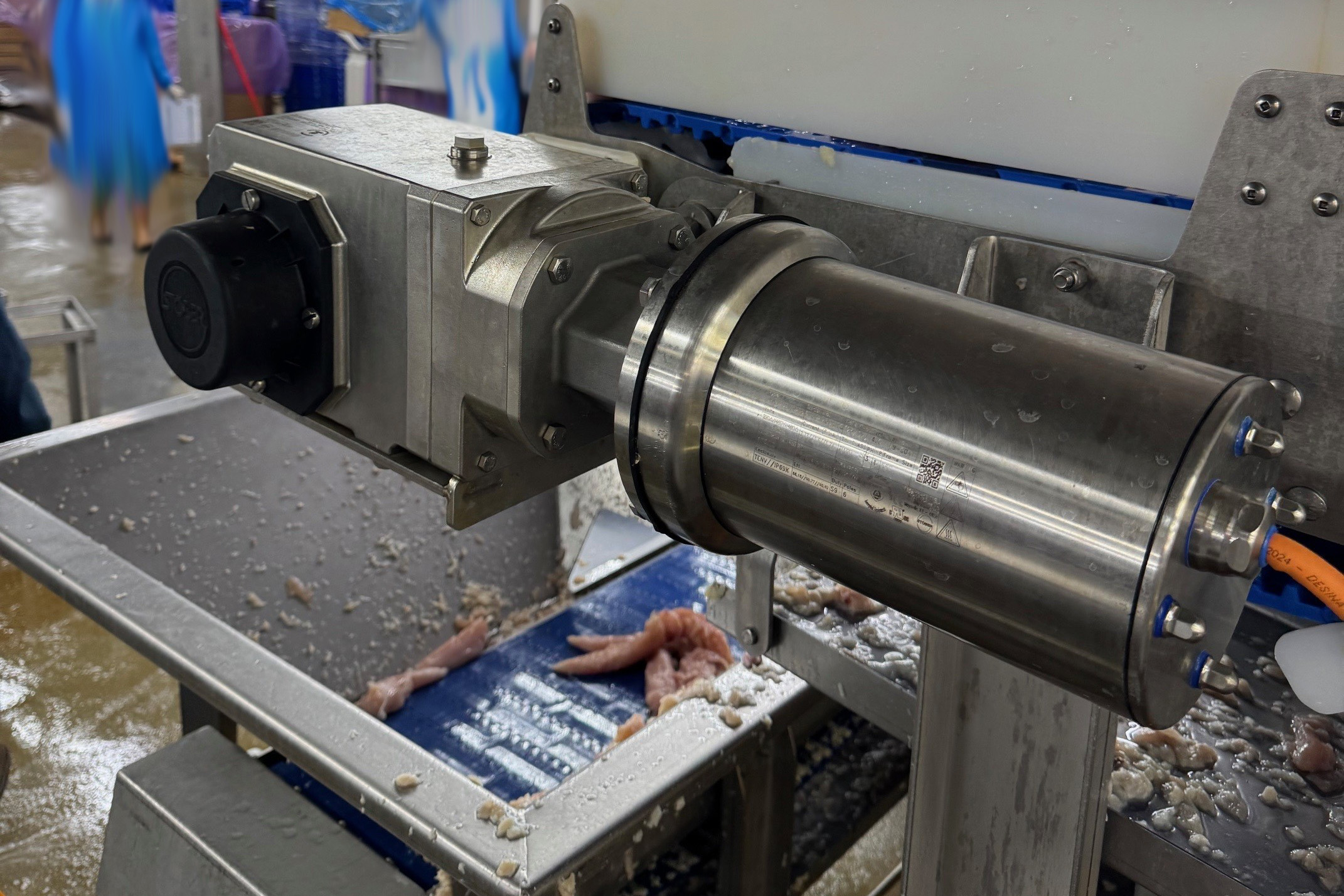

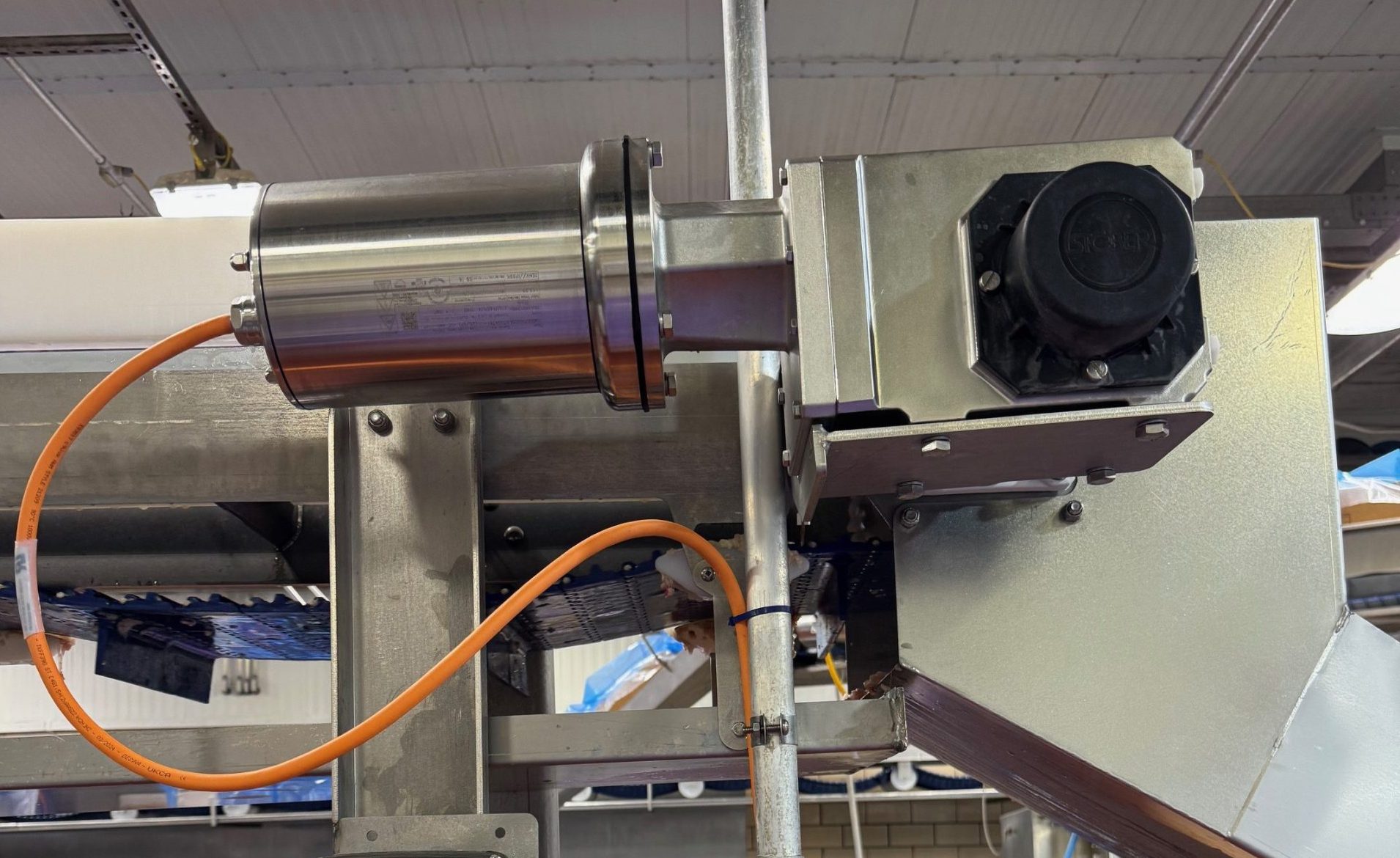

To address the poultry processor’s issues, STOBER helped the facility implement 26 new STOBER conveyor systems on its breast line—outfitted with STOBER’s KSS gearbox and 1 HP cLEAN motor. Designed specifically for food and washdown environments, these components provided the reliability and efficiency the facility needed.

Key selection criteria included:

- High torque capacity

- Robust, wobble-free gearboxes

- Full washdown compatibility

- STOBER’s industry-leading 3-year warranty

While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions, including the cLEAN System, pass the test—preventing premature failure and saving thousands of dollars in downtime.

The results

The poultry plant’s upgrade to the STOBER solution delivered immediate and measurable results, which included:

- Increased uptime & reliability: Drastic reduction in unexpected failures

- Reduced maintenance costs: Fewer repairs and lower labor demand

- Improved efficiency: Smoother operation and enhanced line throughput

- Environmental gains: 66% energy cost reduction, 100% reduction in oil consumption, and recognition as a Green Team Initiative

Some other common food production challenges STOBER is ready to tackle include:

- Limited preventive maintenance capacity – STOBER’s products are no maintenance and no oil changes, so your maintenance crew can focus on other needs.

- Water ingress – Water ingress doesn’t stand a change against STOBER. Dual output seals and an o-ring on the input create a tight seal to prevent water ingress.

- Premature failure from rigid mounting – STOBER offers torque arm mounting options to prevent premature failure from rigid mounting.

- Leaking gearboxes/food safety – At STOBER, our products are no maintenance and no leaks. No more worry about leaking gearboxes, but we offer food-grade oil to comply with all food safety requirements.

A smarter, cleaner solution

By switching to STOBER’s KSS gearbox paired with the 1 HP cLEAN motor, the mid-Atlantic poultry processor not only solved a pressing reliability issue—they also made a long-term investment in operational efficiency, sustainability, and product quality.

STOBER has experience and product knowledge to solve your food production problems. We’re so confident, we offer the industry’s leading warranty and feature an average mean time to failure in a 24/7 harsh washdown environment of 9.1 years. If that’s not enough, you can count on our 24/7/265 support with emergency shipments available if our already fast delivery just doesn’t cut it. Download the PDF below to learn more about STOBER’s hygienic options for the food industry and give us a call to configure your next solution.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025