Today’s fast-paced manufacturing world is constantly demanding more—faster, cleaner, and with less downtime. While automation, sensors, and robotics often shine in the spotlight, one critical component quietly powers the entire system: the gearbox.

At STOBER Drives, we know that the right gearbox can make or break your packaging line efficiency. Here’s why:

1. Precision matters in packaging

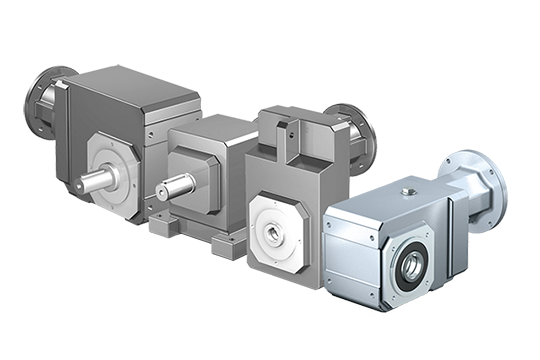

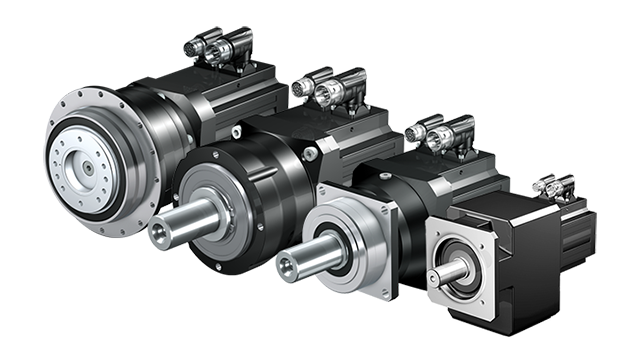

Whether it’s bottling beverages or shrink-wrapping medical devices, packaging operations rely on precise motion control. Misalignment or mechanical play can lead to poor seals, product damage, or even shutdowns. STOBER’s high-precision servo gearboxes are built with minimal backlash to ensure repeatable, accurate movements—each and every time.

2. Speed without sacrificing stability

Packaging lines are a blur of motion, often with a requirement of 24/7 up-time. Those demands require a gearbox that not only delivers speed, but can also handle high dynamic loads without overheating or failing prematurely. STOBER gearboxes are engineered for high-duty cycles and boast superior thermal characteristics, which helps maintain throughput without sacrificing reliability. Optimize without compromise.

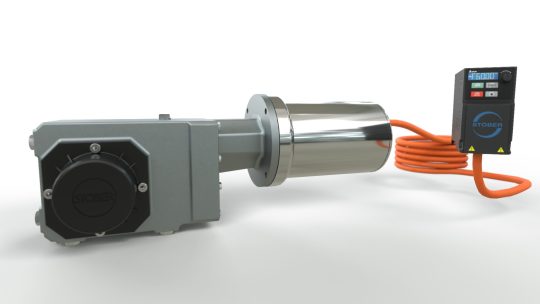

3. Hygiene is non-negotiable

In food, beverage, and pharmaceutical packaging, gearboxes aren’t just mechanical components—they also have strict sanitary requirements to meet. Our food-duty gearboxes and cLEAN System are IP69K rated and made from corrosion-resistant stainless steel, making them ideal for washdown environments. No paint to flake. No places for bacteria to hide.

4. Modular design = flexible lines

Modern packaging lines need to adapt quickly to changing SKUs, formats, packaging, and products. STOBER’s modular gearbox designs allow for easy customization and integration, giving OEMs and engineers the flexibility to design systems that scale and evolve with demand.

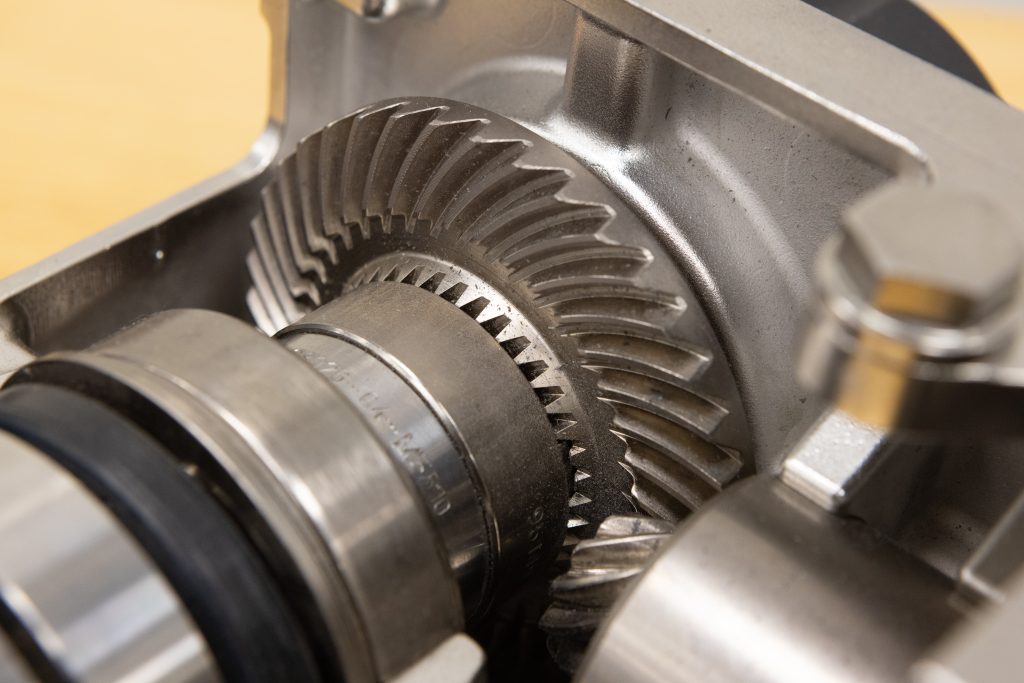

5. Reduced downtime through premium engineering

Every minute a packaging line is down, money is being lost. STOBER gearboxes are built for long life, minimal maintenance, and easy integration, reducing unplanned downtime. Some models feature lifetime lubrication, eliminating the need for oil changes or servicing.

Optimize packaging, one gearbox at a time

Packaging efficiency isn’t just about speed—it’s about precision, reliability, and hygiene. At STOBER, we’ve engineered our gearboxes with packaging applications in mind, delivering the performance that modern production lines demand.

If you’re looking to increase the efficiency of your packaging line, it might be time to take a closer look at what’s driving it.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

Meet the engineers behind STOBER innovation

Meet the engineers behind STOBER innovation  Understanding the different types of geared motors

Understanding the different types of geared motors  Synchronous vs. asynchronous motors: The foundation of servo technology

Synchronous vs. asynchronous motors: The foundation of servo technology  How to calculate gear reduction: Formula, examples & applications

How to calculate gear reduction: Formula, examples & applications