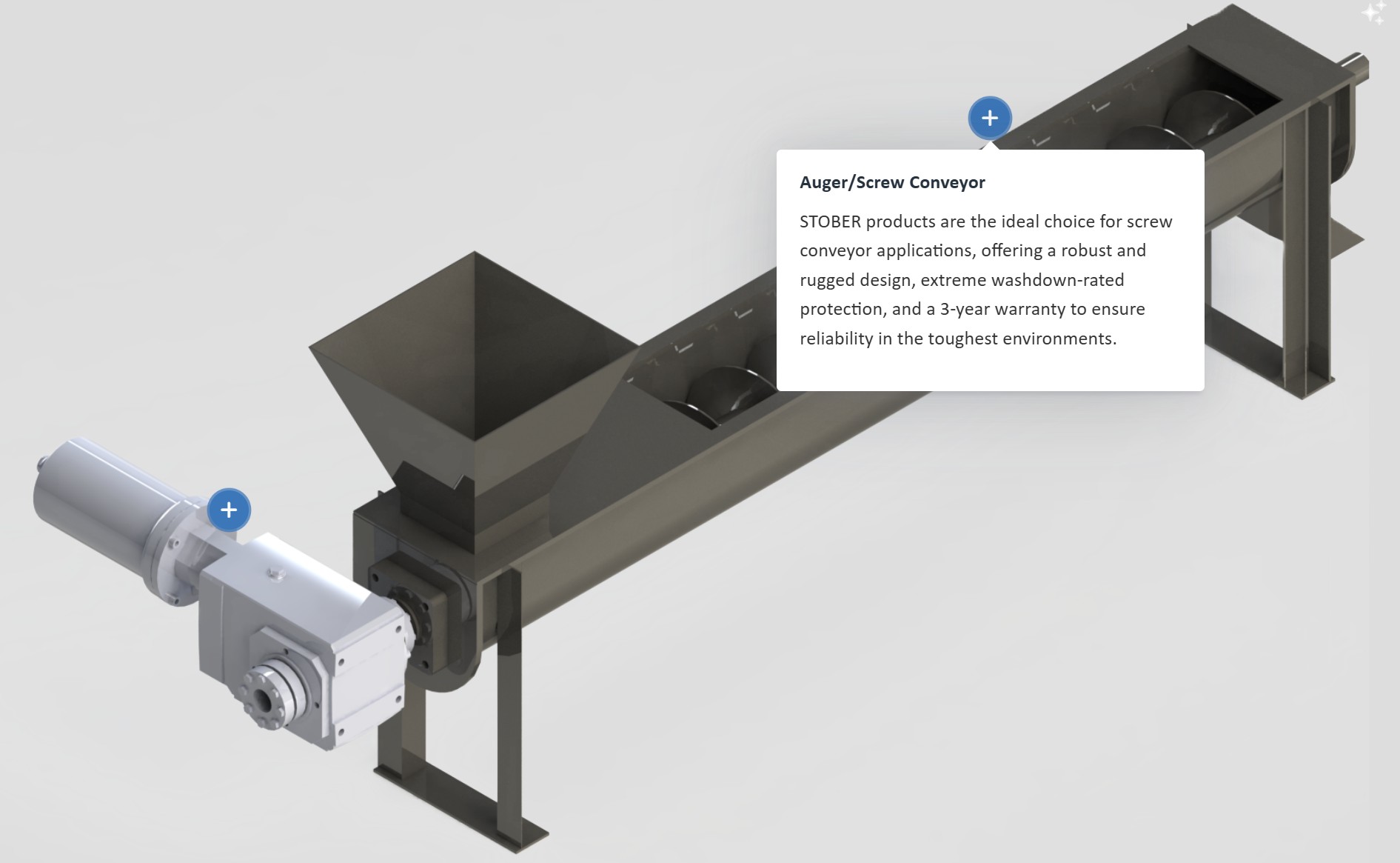

Screw conveyors are a staple in material handling — quietly moving everything from powders and pellets to grains and granules in countless industries. But behind that reliable movement is a powerful drive system that must endure constant torque, handle abrasive conditions, and operate with minimal downtime. That’s where STOBER comes in.

If you’re designing or upgrading a screw conveyor system, STOBER’s inline gearbox solutions with mechanical ratios on the output deliver a level of precision and durability that traditional gear drives struggle to match.

Why screw conveyor applications demand the right gearbox

Screw conveyors are work horses in many different industrial applications, relying on consistent rotary motion to move materials efficiently. The usage of screw conveyors can impact system efficiency, maintenance, and long-term reliability. In a series of blogs, we will take a look at different usage options, beginning with an inline gearbox with mechanical ratio on the output.

In this common setup, an inline gearbox drives a chain & sprocket or belt & pulley to operate the screw conveyor. The gearbox must not only transfer power from the motor to the screw shaft but do so reliably over long operating hours — often in dusty, dirty, or corrosive environments. This design typically places a bearing between the screw and bolt, separating the STOBER components from the thrust load produced from the screw itself.

The inline option is commonly used when an inline gearbox is already in place and the customer refuses to change. It’s also common when direct mounting isn’t possible due to total torque produced by customer’s existing screw conveyor package.

While this solution is compact and ensures separation during loading, some common challenges of this setup include:

- High shock loads and torque requirements

- Precise speed control to match material flow rates

- Maintenance access in tight plant layouts

- Long service life with minimal intervention

An improperly sized or low-quality gearbox can lead to misalignment, inefficiency, and costly breakdowns. That’s why engineers turn to STOBER.

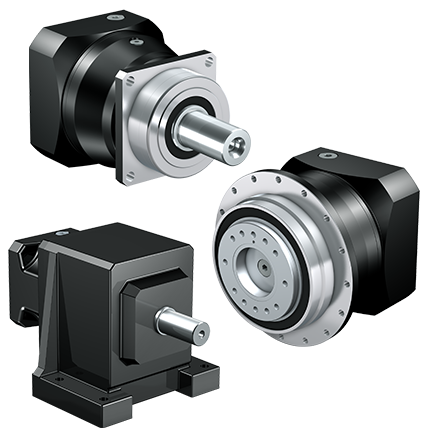

STOBER’s inline gearbox with mechanical output ratio: A smart fit for screw conveyors

At the heart of our solution is the STOBER C-series helical inline servo gearbox paired with a mechanical ratio on the output based on the horsepower and ratio desired. This delivers rock-solid performance where it matters most, and is a proven solution when direct mounting isn’t an option.

For customers who are open to or considering redesigning, a better long-term solution would be a direct-mount K-series reducer, assuming there is room in the backside screw trough.

Key benefits:

- Inline configuration: Keeps the motor and screw shaft in line for a compact footprint — ideal for space-constrained installations.

- Mechanical output ratio: Allows precise speed and torque control without sacrificing efficiency. Excellent for matching conveyor requirements to motor speed.

- High torque capacity: STOBER gear units are engineered to handle high continuous loads and start-stop cycles — ideal for bulk material applications.

- Sealed for life: With lifetime lubrication and IP-rated sealing, maintenance is minimal — even in harsh environments.

- Mounting flexibility: Whether you’re retrofitting an existing screw conveyor or building new, STOBER offers versatile mounting options that simplify integration.

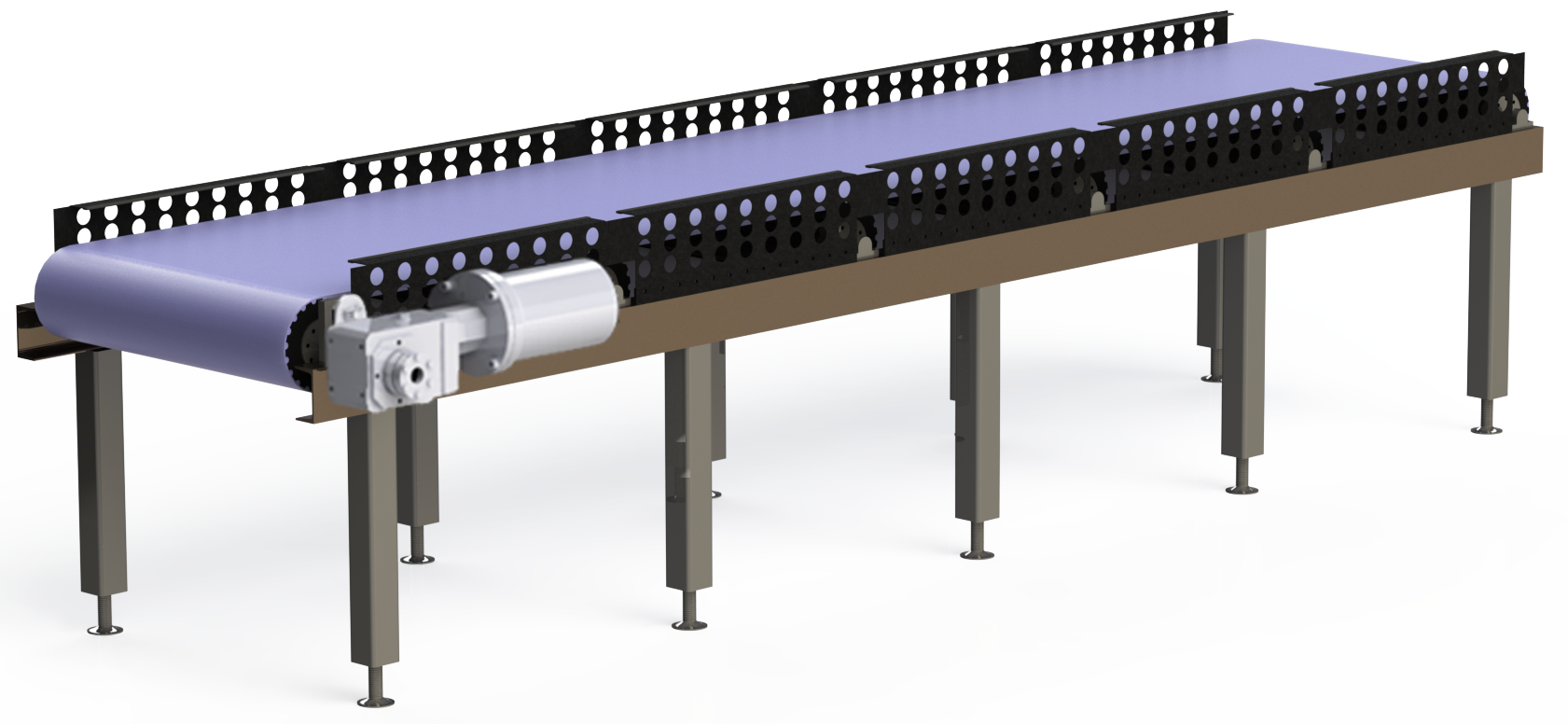

Applications in the field

STOBER inline gearboxes have been successfully implemented in screw conveyor systems across industries such as:

- Food & beverage – conveying flour, sugar, grains

- Pharmaceutical – powders and fine materials

- Plastics – pellet transfer and extrusion feed systems

- Agriculture – feed delivery and grain movement

- Mining & aggregates – sand, cement, and other heavy materials

Our gearboxes are engineered to meet the unique torque and speed demands of each application while reducing maintenance and extending operational uptime.

Engineering support that sets us apart

At STOBER, we don’t just ship gearboxes — we support customers through every step of the design process. Whether you need help selecting the right mechanical output ratio or want guidance on adapting your motor to our gear unit, our team is here to help.

We also offer:

- Rapid delivery times and responsive support

- Application-specific CAD files

- Custom shaft and mounting configurations

Ready to optimize your screw conveyor system?

If you’re designing or upgrading a screw conveyor and need a gearbox solution that delivers torque, reliability, and precision, STOBER has solutions that are up to the task.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025