As the components responsible for controlling speed, torque, and direction in motors, gearboxes are some of the mosit important elements in a modern industrial facility. They ensure the proper and precise functionality of all kinds of equipment from powered conveyor belts to advanced robotic assembly arms. Given how crucial they are, it’s important to know when your equipment needs maintenance to prevent costly breakdowns and extensive industrial gearbox repairs. Here are eight of the most common industrial gearbox warning symptoms that may indicate gearbox repair is needed.

1. Unusual noises

If a gearbox begins making grinding, whining, or rattling noises, that’s a clear sign that something is wrong. Scraping or grinding sounds may indicate worn-out or damaged gears, while any whining or humming noises could be the result of a bearing failure or insufficient lubrication. If there’s rattling, chances are there may be some loose components inside the gearbox.

2. Excessive vibrations

A gearbox that begins to vibrate more than expected means the unit is off-balance, which can lead to instability throughout the machinery. This may be caused by misaligned components as well as worn bearings or gears. There’s also a chance the issue may be elsewhere in the equipment, so it’s a good idea to look beyond the gearbox when this occurs.

3. Oil leaks

Seals that are old or damaged can cause oil to leak out of the gearbox. This can lead to the gearbox losing much-needed lubrication as well as the possibility of contaminants entering the unit. In both cases, the lifespan of the gearbox can be negatively affected. Regular checks are necessary to spot any leaks as soon as possible and prevent industrial gearbox failure.

4. Overheating

Excessive heat can have a negative impact on the performance and longevity of a gearbox, which is what makes checking the temperature of these components so important. Overheating typically is caused by insufficient lubrication or overloading the equipment beyond its specified capacity. If you notice these issues cropping up frequently, make sure the machinery is properly ventilated and pay attention to the environmental conditions surrounding it.

5. Decreased performance

A faulty gearbox that delivers reduced output or slower speeds than normal requires attention as soon as possible. There could be a host of issues at play, from improper use of lubricants to worn gears to faulty bearings. Addressing these gearbox problems as soon as they are found is key to restoring proper performance and productivity.

6. Gear slipping or sticking

When gears start to slip inside the gearbox, the culprit is most often worn teeth. Replacing these gears with new parts should alleviate this issue. If the gears are sticking, the problem is probably a lack of lubrication or a faulty synchronizer.

7. Unstable oil pressure

If the oil pressure is too low, it can have an adverse effect on lubrication levels and lead to premature gearbox failure. In most cases, this is the result of a damaged oil pump or a blockage in the lines.

8. Frequent shutdowns or stops

A gearbox that fails to engage or stops altogether can cause shutdowns throughout your operations. The most common causes of unexpected shutdowns in gearboxes are seized gears or excessive strain.

The importance of timely gearbox maintenance

Protecting your facility’s gearboxes is crucial for keeping your production level high and preventing costly shutdowns. If you happen to notice any of the warning signs listed above, it’s important to reach out and contact a professional to provide industrial gearbox repair service and keep your facility running as smoothly as possible.

When repair isn’t enough — signs you may need replacement

Sometimes repair won’t solve the underlying gearbox issue. Recognizing when to replace instead of repair helps avoid repeated failures and long-term inefficiencies.

Frequent failures

Repeated breakdowns are strong gearbox malfunction indicators. If the same failure recurs despite repairs, internal damage may be beyond correction. Continuous reassembly with replacement parts becomes less viable and can degrade system reliability.

Severe wear and damage

Extensive gear tooth wear, missing teeth, or cracked housings signal irreversible damage. In these cases, replacement is the safest and most cost-effective path forward. Gearbox failure that compromises shaft balance or bearing seats often requires full rebuilds. At a certain point, investment in a new unit provides greater returns in uptime and dependability.

Obsolete gearboxes

For legacy systems where parts are unavailable, replacement ensures continued serviceability. Upgrading outdated models improves reliability and integrates better with modern diagnostics tools. It also allows access to newer technologies like sealed-for-life designs or maintenance-free bearings.

Changing operational demands

If production speeds or loads exceed the gearbox’s original design, upgrading to a higher-capacity system reduces the risk of signs of gearbox overload and performance degradation. Replacement gearboxes can be tailored for thermal management, tighter gear tolerances, and enhanced torque ratings to meet future production goals.

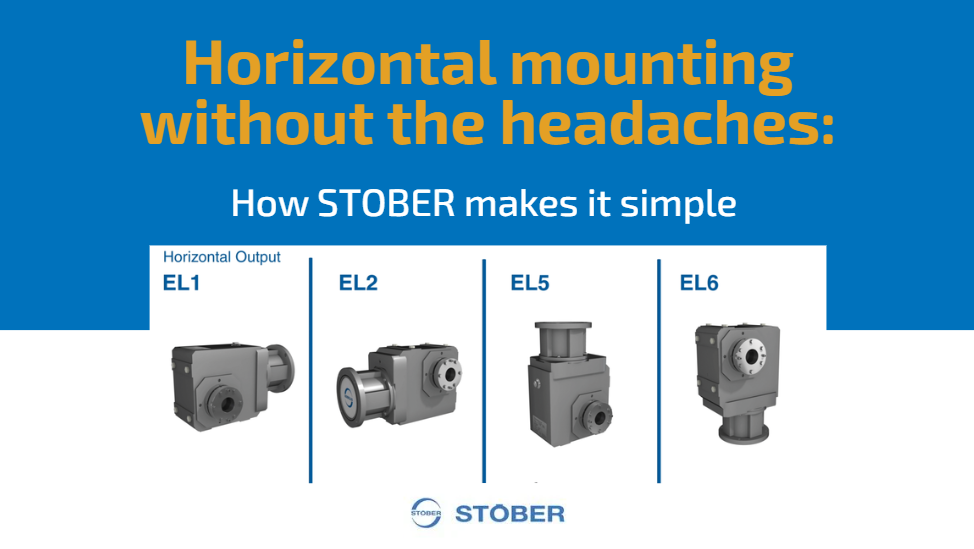

How STOBER supports long-term gearbox health

STOBER Drives, Inc. is committed to keeping your operation running with dependable solutions, responsive service, and proven durability.

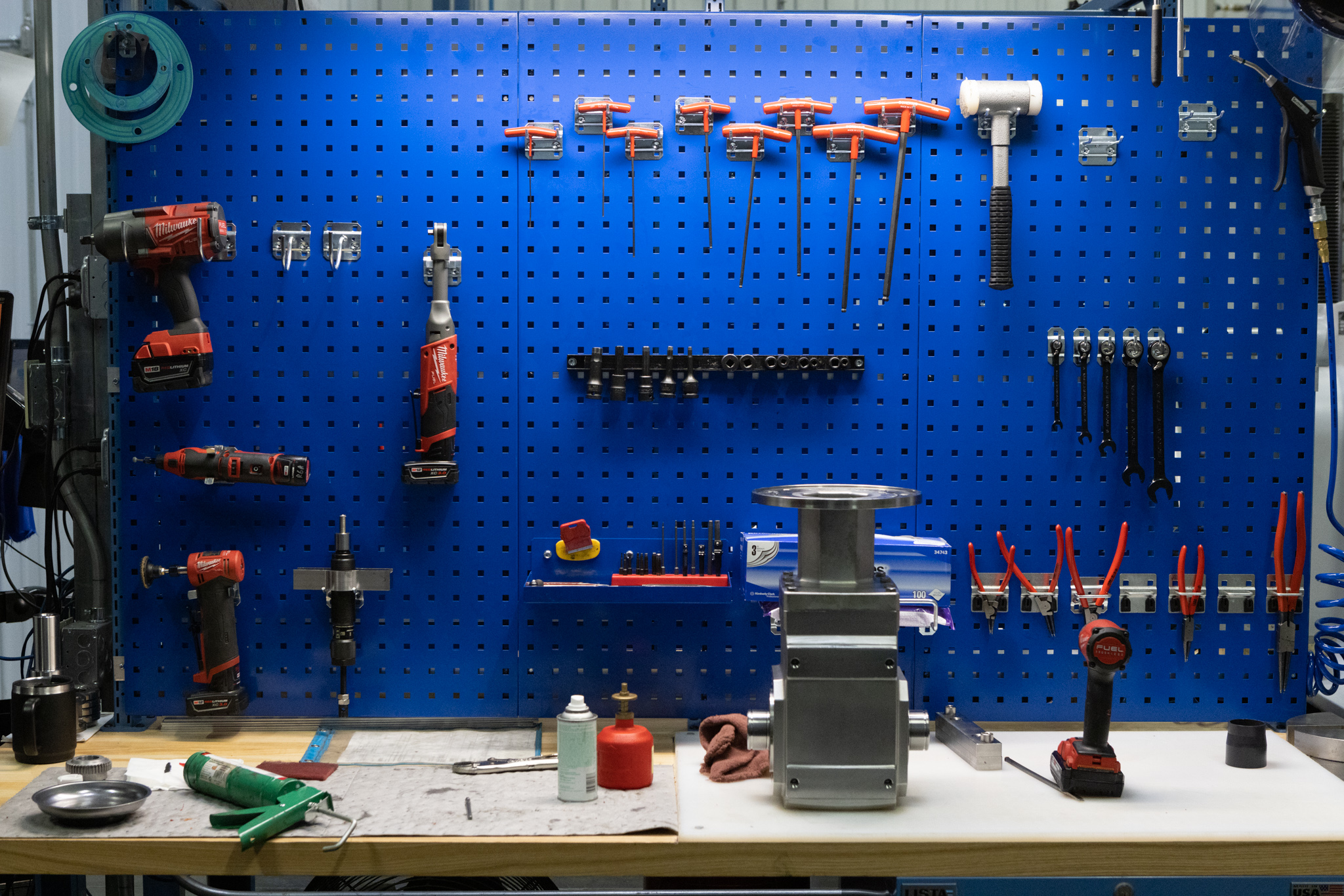

Modular design for efficient service

STOBER gearboxes are built with modular designs, making inspection, retrofitting, and part replacement fast and simple. This reduces downtime and enhances maintenance efficiency. Gearbox mounting options, shaft configurations, and adapter components are all designed for flexibility and interchangeability.

Fast lead times

When failure occurs, STOBER offers one-day build and ship capabilities from its Kentucky facility. Quick delivery helps teams respond to gearbox failure without extended delays. That responsiveness helps you avoid idle machines and reduce reliance on temporary workarounds.

Expert engineering and support

From initial sizing to in-depth gearbox troubleshooting, STOBER’s engineering team is ready to assist. Support is available 24/7, ensuring help is there when you need it most. Whether it’s addressing gearbox misalignment issues or providing drawings for replacement parts, STOBER’s team delivers prompt, accurate answers.

Specialized solutions for tough environments

STOBER’s cLEAN System, featuring IP69K-rated stainless steel geared motors, is ideal for washdown-heavy industries like food and beverage. These systems are designed to resist water ingress, harsh cleaning chemicals, and extreme conditions, preventing early wear and extending service life. The design helps prevent difficulty shifting gears due to corrosion or contamination.

Comprehensive service ecosystem

From preventive maintenance to emergency repair, STOBER provides the tools, expertise, and reliability that today’s industries demand. When you need solutions for any gearbox problem — from gearbox lubrication failure to gearbox misalignment issues — STOBER is your partner for long-term success.

If you’re wondering how to tell if gearbox is failing, or want help developing a predictive maintenance program, STOBER is ready to support you with gear unit and servo motor solutions every step of the way.

Learn more about service options from STOBER by clicking the link below or contact us at (888) 786-2371 or email sales@stober.com.

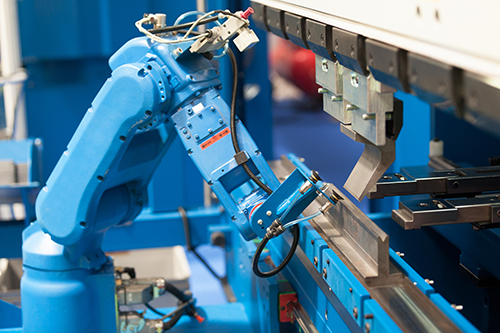

Selecting gearboxes for robotic & industrial automation systems

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices