One of the largest poultry processing facilities in the U.S. was struggling with recurring failures within a critical area of its production line. A key conveyor system experienced frequent motor failures caused by severe washdown conditions, resulting in costly downtime, increased maintenance demands, and disruptions to production flow. The customer needed a solution engineered for durability, efficiency, and long-term performance.

Industrial motor reliability challenges in poultry processing

The customer’s existing competitor motors were failing due to water ingress in a demanding chiller outfeed conveyor application. These failures led to:

- Rising maintenance labor

- Unplanned downtime

- Reduced throughput

- Escalating replacement costs

These recurring breakdowns impacted production flow and required repeated maintenance interventions. The customer needed equipment that could thrive in harsh, high‑moisture environments without compromising uptime. With no signs of improvement using traditional motor options, the facility sought equipment engineered for extreme environments.

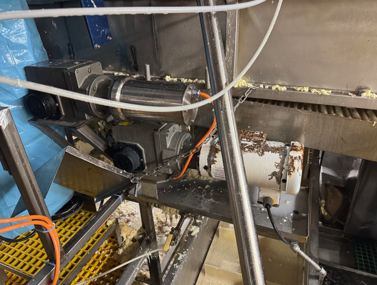

The STOBER solution: A reliable drive system for high‑washdown environments

To address the recurring downtime and reliability issues, the facility upgraded the application by installing two STOBER cLEAN motors designed specifically for demanding, high‑washdown food processing environments. These motors deliver exceptional durability, efficiency, and torque performance while eliminating the water‑ingress problems previously experienced with competitor units. The system also utilized existing STOBER food‑duty gearbox technology already proven on the line, creating a fully integrated, highly robust drive solution. Backed by STOBER’s industry‑leading 3‑year warranty, the new setup provided the long‑term reliability and hygienic design the customer needed to stabilize production and reduce maintenance burdens.

Operational improvements after upgrading to STOBER

Since installing STOBER technology, the poultry processor has seen substantial performance improvements, improved operational reliability, and reduced maintenance burden. The chiller outfeed conveyor now runs consistently, resulting in:

- Increased production uptime

- Lower maintenance frequency and labor requirements

- Improved energy efficiency (motor efficiency increased from 86.5% to 91%)

- More consistent conveyor line performance

The increased motor efficiency also contributes directly to energy savings and greater operational stability.

Cost Savings & ROI for the Facility

The switch to STOBER is projected to generate $72,000 in savings over a 3‑year period, driven by:

- Energy improvements

- Fewer repairs, lower maintenance costs

- Reduced downtime

- Longer product life compared to competitor motors

The overall return on investment (ROI) for the project is only 67 days!

Why food processors choose STOBER for high‑washdown applications

Food processors choose STOBER for high‑washdown applications because these environments demand equipment that can withstand aggressive sanitation procedures while still delivering exceptional efficiency and uptime. STOBER cLEAN motors provide the hygienic, fully sealed design required for rigorous washdown conditions, along with long‑term durability, improved energy performance, and a reduced total cost of ownership.

Beyond superior product performance, STOBER is known for its unwavering commitment to quality, ensuring that every motor and gearbox is engineered with precision and built to last in demanding food production environments. Customers also rely on STOBER’s dependable delivery, which keeps projects moving and minimizes production delays. Just as importantly, STOBER’s responsive and knowledgeable service team provides ongoing support, giving food processors confidence that they have a trusted partner ready to assist whenever challenges arise.

Ready to see more real‑world results?

Explore additional case studies and customer success stories to learn how STOBER helps manufacturers boost reliability, efficiency, and production uptime.

Selecting gearboxes for robotic & industrial automation systems

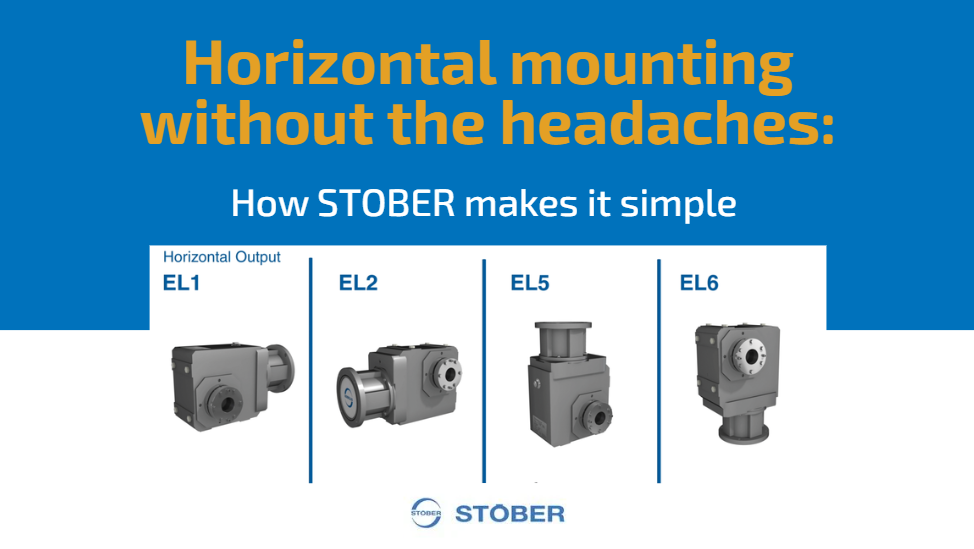

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs