The gearbox is the heart of an operation. When it runs smoothly, productivity stays high, downtime is minimized, and costs remain under control. But just like any piece of industrial equipment, gearboxes don’t last forever. Knowing when to repair versus when to replace can save your facility both time and money.

STOBER’s OEM Renewal Program extends the life of gearboxes, geared motors, and geared machines, resulting in a huge cost savings. STOBER products are synonymous with reliability and longevity with a mean time to failure of more than 9.1 years. At STOBER, we’ve seen gearboxes last decades with proper care — but eventually, replacement is the smarter move. Here are five key warning signs that it’s time to start planning for a new gearbox:

1. Excessive noise or vibration

Gearboxes are designed to run quietly and efficiently. If you notice unusual grinding, clunking, or vibration, it may be a sign of internal wear. Bearings, gears, or shafts could be reaching the end of their lifecycle. While minor issues can sometimes be repaired, recurring noise is often an indicator of deeper problems that signal replacement.

2. Overheating during normal operation

Excess heat can shorten the lifespan of lubricants and cause thermal expansion, leading to misalignment and accelerated wear. If your gearbox is running hotter than usual — even under normal loads — it may be operating inefficiently or near failure. Modern solutions, like STOBER’s lubed-for-life units, are designed to minimize heat buildup and ensure consistent performance.

3. Frequent leaks or lubrication issues

Lubrication problems are one of the most common reasons for gearbox failure. Persistent oil leaks, contaminated lubricant, or the need for constant top-offs suggest the seals or housing are compromised. At this stage, repair costs can add up quickly. Lubed-for-life gearboxes eliminate these issues altogether, removing lubrication maintenance from your checklist.

4. Declining efficiency and output

If your system isn’t delivering the torque or speed it once did, your gearbox may be losing efficiency due to wear and tear. This not only impacts performance but also drives up energy costs. An inefficient gearbox can drain your bottom line without you realizing it. Replacing it with a high-efficiency design helps restore productivity while lowering operating expenses.

5. Rising maintenance costs and downtime

When you find yourself scheduling more service calls, stocking more spare parts, or dealing with recurring breakdowns, it’s often more cost-effective to replace the gearbox entirely. Frequent downtime cuts into production schedules and strains your maintenance team. A new gearbox, especially one designed for durability and long service life, reduces unplanned interruptions.

Why choose STOBER for replacement?

Not all gearboxes are created equal. STOBER gear drives are built to last longer, run cooler, and operate with zero maintenance. With lubed-for-life designs, robust construction, and precision engineering, our gearboxes boast a mean time to failure of more than 9.1 years and give you peace of mind that your investment will pay off for years to come.

Whether you’re replacing a failing unit or upgrading for better performance, STOBER provides the reliability and efficiency your operation depends on.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

Ideal gearbox selection: Practical sizing checklist to save money

Ideal gearbox selection: Practical sizing checklist to save money  STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

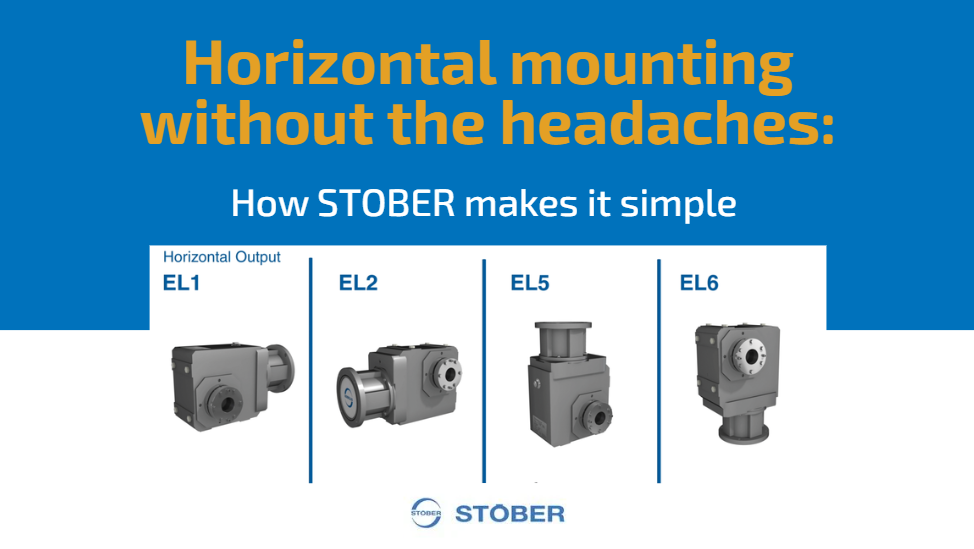

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple