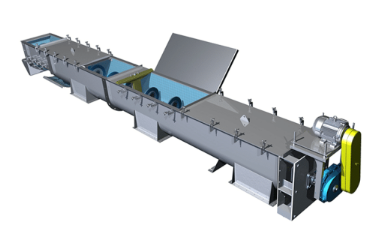

From agricultural grain handling to heavy-duty industrial processing, Screw conveyors efficiently move a variety of materials with minimal effort. However, the effectiveness of any screw conveyor depends on the drive system powering it. STOBER’s solutions for scoop-mount direct drives help elevate performance, efficiency, and reliability.

What is a screw conveyor?

A screw conveyor is a mechanical device that uses a rotating helical screw blade—called a “flighting”—to move granular or semi-solid materials through a tube or trough. They’re used in a wide range of industries for tasks such as:

- Moving grains, cereals, and animal feed in agriculture

- Transporting powders and pellets in plastics processing

- Handling sludge or biomass in wastewater treatment

- Feeding or metering ingredients in food manufacturing

Because these conveyors are often exposed to harsh conditions and continuous operation, reliability and drive efficiency are key.

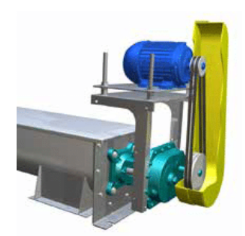

Why use a scoop mount direct drive?

Traditional screw conveyors often use belt-driven or shaft-mounted motors with external bearings and couplings. While these systems work, they can introduce alignment issues, require more maintenance, and occupy more space.

A scoop mount direct drive is a more compact and integrated solution. In this configuration:

- The drivetrain uses a motor connected to a belt drive or chain and sprocket paired with the input shaft of a direct-drive shaft-mounted gearbox

- This approach powers the screw conveyor while the gearbox manages the thrust produced

- There are no external couplings or bearings needed

- Power is transmitted more efficiently, with fewer components to maintain or fail

The result? A streamlined, compact design that offers higher reliability, reduced maintenance, and greater efficiency.

STOBER Drives: The ideal partner for screw conveyors

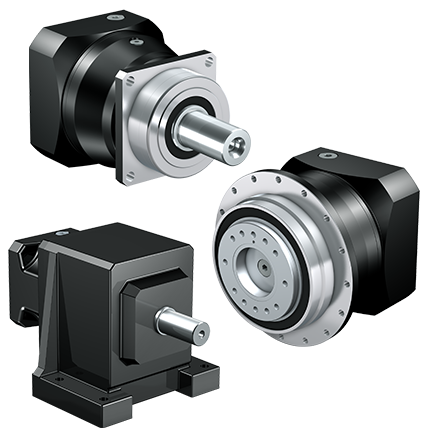

STOBER is known for its high-performance gear drives and servo systems, and the K-series gearbox is engineered to tackle challenging screw conveyor applications.

Key benefits of STOBER K-series:

1. Compact, robust design

STOBER’s gear units are designed for harsh environments, offering IP-rated protection, rugged construction, and compact footprints—perfect for tight spaces or retrofit projects.

2. No alignment needed

With a direct-mount setup, STOBER drives eliminate the need for alignment between the motor and screw. This not only simplifies installation but also reduces downtime due to misalignment-related failures.

3. Lubrication-free motor connection

The motor connection is completely sealed and requires no external lubrication—ideal for industries with hygiene or contamination concerns like food, pharma, or chemicals.

4. Maintenance-friendly

By removing couplings, belts, and external bearings from the equation, STOBER’s system greatly reduces wear parts, leading to less maintenance and longer uptime.

5. Energy efficiency

Their high-efficiency gear motors, including options with IE4 efficiency class, help facilities meet sustainability goals and reduce energy costs.

Applications in the field

Here are some real-world examples where STOBER scoop mount drives shine:

Food production: With clean-in-place requirements and FDA-approved materials, STOBER systems offer hygienic solutions for screw conveyors in food processing lines.

Grain elevators: In agricultural setups, where uptime during harvest season is critical, STOBER offers peace of mind with durability and minimal maintenance.

Wastewater facilities: Harsh, wet, and often corrosive environments demand robust systems—STOBER’s sealed and IP-rated drives are up to the challenge.

Ready to optimize your screw conveyor system?

Whether you’re designing a new bulk material handling system or retrofitting an existing conveyor, choosing the right drive solution can significantly impact your operational efficiency. STOBER’s direct-mount K-series reducer provides a reliable, low-maintenance, and space-saving alternative to traditional drive configurations—perfect for the rigorous demands of screw conveyor applications.

STOBER offers a wide range of gear units and mounting options to meet specific application needs. If you’re looking to increase uptime, reduce maintenance, and streamline your conveyor systems, STOBER might be the partner you’re looking for.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

Happy retirement, Terri Fisher!

Happy retirement, Terri Fisher!  STOBER solutions for screw conveyor applications: Inline gearbox

STOBER solutions for screw conveyor applications: Inline gearbox  How industrial gearbox technology is evolving

How industrial gearbox technology is evolving