Having the right equipment is important for any industrial process. Without the right tools in place, processes may be ineffective and inefficient—if they work at all. Unfortunately, there can be a lot of confusion between industries about which tools and components are right for the job because each sector has its own needs and, in many cases, its own terminology.

Take, for example, the difference between a gear reducer vs. a gearbox. Although these terms typically refer to two distinct components, sometimes users and even manufacturers may use them interchangeably, creating confusion. This can lead to serious delays in upgrades or retrofits that can take a bite out of productivity. Anyone working within a high-performance industrial environment needs to know the difference between a gearbox and a gear reducer, and when each one should be used.

Part of what makes the question so confusing is that although all gear reducers are gearboxes, not all gearboxes are gear reducers. However, understanding the basics behind each type of component should make it much easier for operators to distinguish between the two.

What is a gearbox?

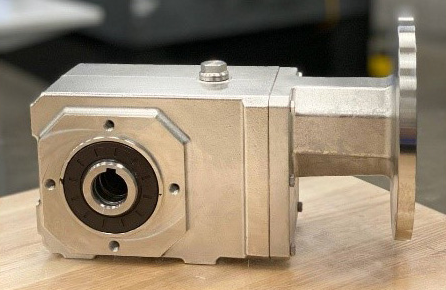

In the simplest of terms, a gearbox is exactly what it sounds like. It’s a collection of gears inside a housing that serves the function of transmitting mechanical power between two elements of a machine. Rather than simply transferring power 1:1, however, a gearbox’s primary job is to change its nature. It can accomplish this by increasing it, decreasing it, changing the amount of torque, redirecting it, or a combination of these. It can be designed as a speed reducer, to increase speed, or provide more precise torque control.

There are several different types of gearboxes, including planetary, helical, bevel, worm and parallel shift. These differ based on the size and configuration of the gears inside and the adjustments to power they provide inside a machine. This variability means gearboxes serve many types of functions inside machine tools, conveyors, robotic automation systems, vehicle transmissions and more.

What is a gear reducer?

Within the broader category of gearboxes is a subset known as gear reducers. These are designed specifically to reduce speed and multiply torque within a system. In many cases, gear reducers are used to match the high-speed output of a motor with the lower-speed operation required by the equipment for proper functionality. One of the most important purposes they serve is to ensure manageable torque and RPM to protect downstream equipment from excessive wear and tear. For example, using a 10:1 gear reducer brings the output of a 1,750-RPM motor down to 175 RPM.

Gear reducers also feature fewer variations than other types of gearboxes, which is understandable considering their specific applications. Most gear reducers feature either planetary or helical gearing and may be configured as right-angle or inline.

Key differences between gearboxes and gear reducers

TGearboxes and gear reducers stand apart from each other in a few very important ways:

- Functionality: Gearboxes can be used to modify speed up or down, transmit torque or alter the direction of power. On the other hand, gear reducers serve only to reduce output speed and increase torque.

- Applications: A gearbox may be found in a wide range of equipment across multiple industries. However, gear reducers typically are concentrated into equipment used for automation, material handling and manufacturing systems. This is because these industries frequently need to reduce speeds from motors to something more manageable.

- Configurations: Gear reducers, due to their narrower range of functions, tend to be relatively simple compared to other types of gearboxes. Components that serve other functions may include reducers as well as synchronizers or other gearing arrangements. ion.

How to select the right component for your application

Being able to know which type of component is the best fit for your application is essential for gearbox system optimization. When choosing a gearbox or gear reducer, it’s important to keep a few things in mind:

- Desired output speed and torque.

- Input motor specs including RPM, horsepower and mounting style.

- Load characteristics and duty cycle.

- Space constraints and orientation.

- Environmental conditions.

- Industry-specific requirements.

Working with an experienced engineering team like the professionals at STOBER means you can take the guesswork out of this process. With the right expertise at your side, you can ensure you have the proper sizing, configuration and long-term reliability for your needs. This means you won’t have to worry about oversizing, underperformance or premature failure when it comes to your gearboxes.

Why understanding the difference matters

Knowing when you need a gearbox vs. a reducer in your industrial machinery is critical for making informed decisions about your equipment when it’s time to upgrade or replace components. Having clarity in the terminology you use internally means you can communicate more effectively with your vendors and prevent confusion.

As a leading manufacturer of robust gearboxes, STOBER can be your one-stop shop for expertise in choosing the right solutions as well as the components you need. When it comes to optimized motion solutions, we can provide you with high-quality reducers to prevent downtime as well as other gearboxes to fit your precise requirements. Our experience also means you can be sure you’ll have the proper alignment so your gearboxes will deliver the power and performance you need.

To learn more about our complete range of solutions and how they can boost your facility’s productivity, reach out and speak with one of our knowledgeable representatives today.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

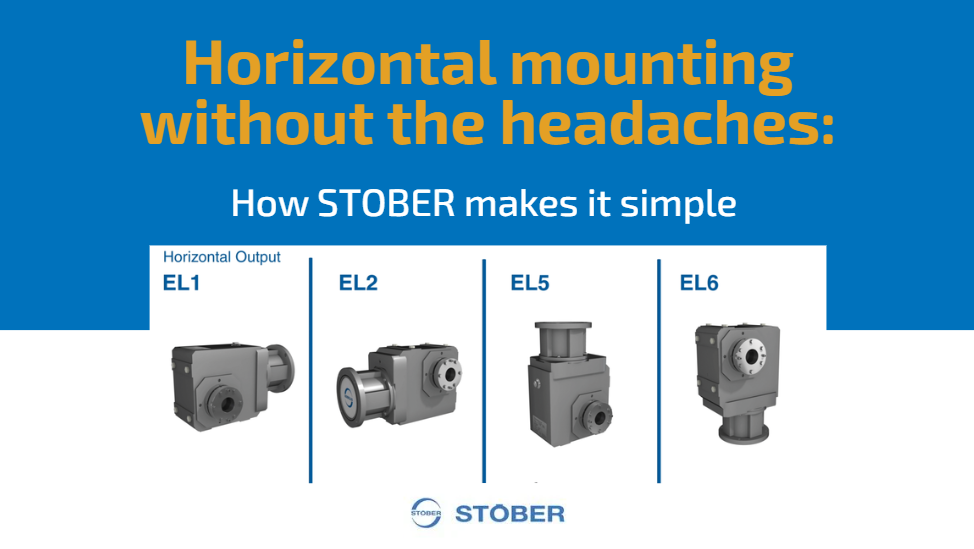

Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory