Synchronous Servo Motors

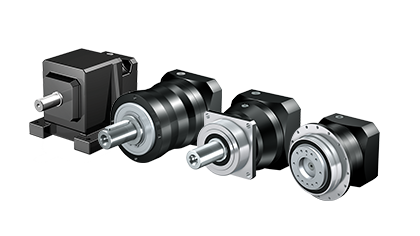

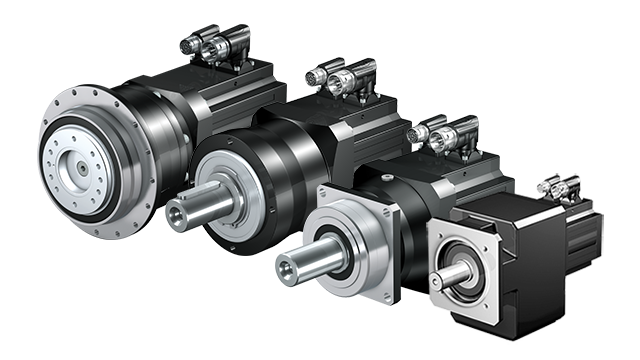

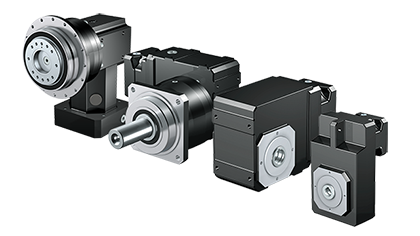

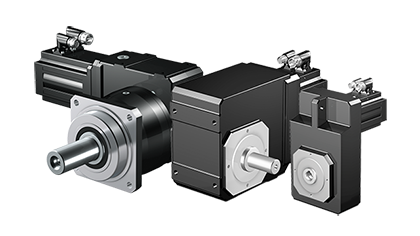

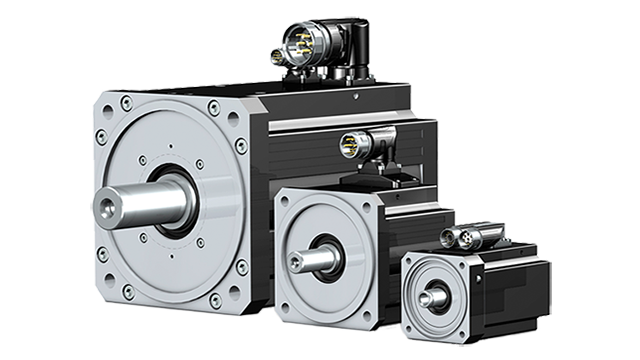

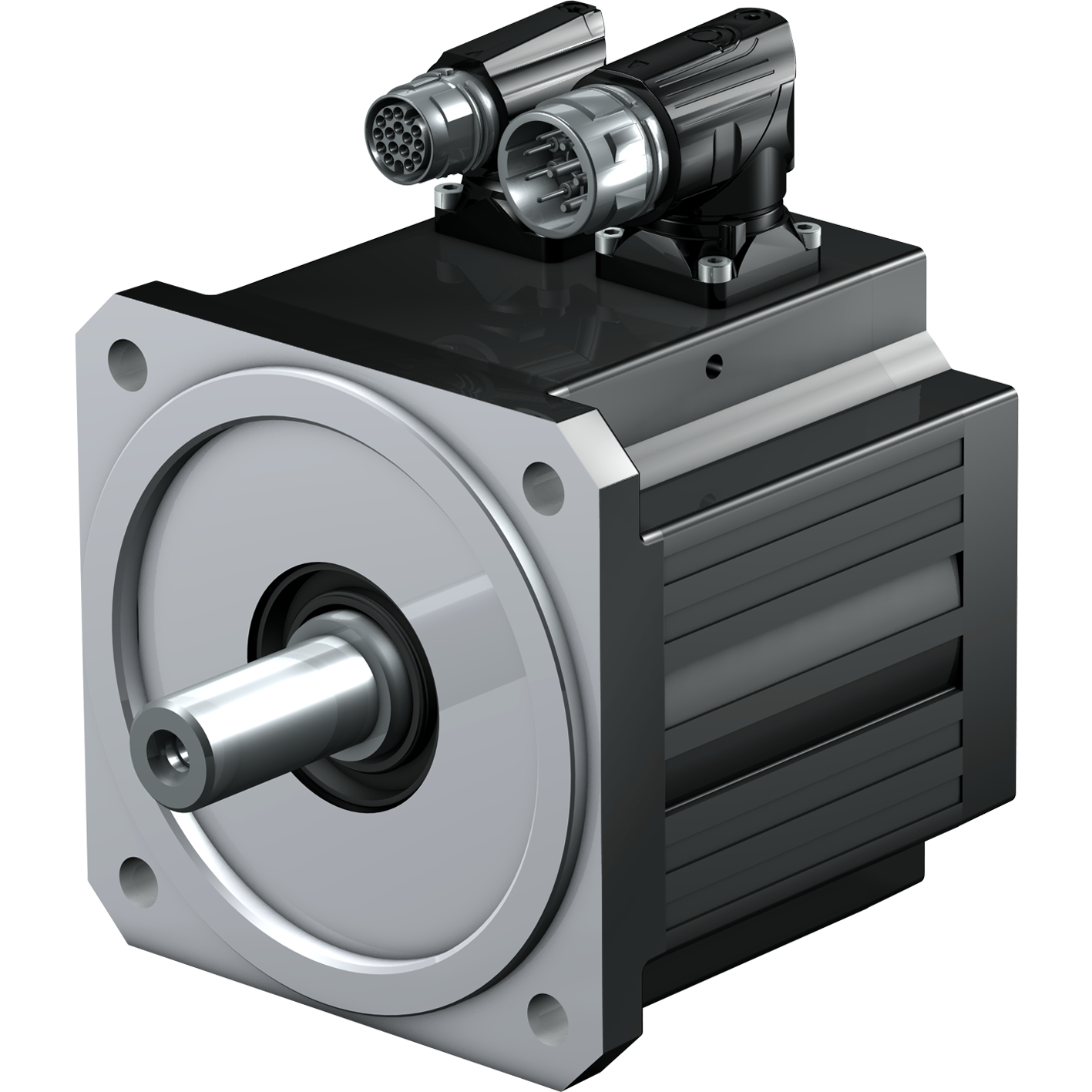

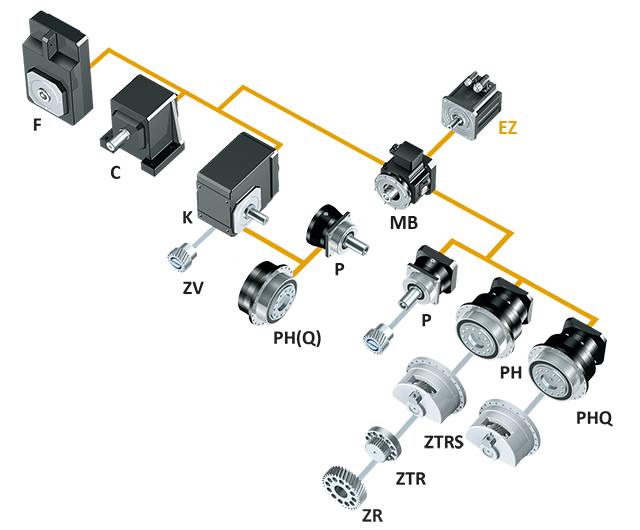

With the EZ synchronous servo motor, STOBER is offering brushless, permanent magnet and electronically commutated motors with different power profiles. The stator and rotor components have an optimized design in relation to energy for extremely low torque ripple and a high-power density in various forms.

Our synchronous servo motors deliver exceptional performance no matter what the application. Customers across the aerospace, automotive, material handling and other industries value them for their compact design, dynamic capabilities and versatility. These compact servo motors feature a shaft for easy connections.

Perhaps best of all, STOBER’s ability to design customized solutions means we have the skill to develop the ideal motor for your needs even if our stock units don’t quite fit. We’re committed to finding new ways to solve your problems, and we’re ready to meet the challenge no matter what you may be facing.

The EZ series utilizes a shaft for connecting.

It is extremely compact and dynamic, providing measurably better performance.

EZ Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Stall torque: .95 – 94

- Nominal torque: .89 – 77.2 Nm

- Nominal Speed: Up to 6,000 RPM

EZ Series: FEATURES

- STOBER geared motor are fully supported with the drive manufacturers listed below. They are compatible with EnDat, Hiperface DSL, and Resolver.*

- Beckhoff

- Bosch

- B&R

- Control Techniques

- Kollmorgen

- Rockwell

- Siemens

* Note: Not all options are available for every drive.

- Brakes:

- Holding brake – ideal for vertical applications or maintaining position

- IP Ratings:

- 65 – standard

- 56

- 66

- Encoders:

- Hiperface DSL (Rockwell)

- EnDat

- Single-turn

- Multi-turn

- Optical

- Inductive

- 2.1

- 2.2

- Resolver

- Fan:

- Increase torque and cool system without upsizing to larger motor

What is a synchronous servo motor and how does it differ from other motor types?

A synchronous servo motor serves to maintain a constant speed relative to the input frequency, which makes it ideal for high-precision applications across multiple industries. Compared to asynchronous motors, these tend to be more efficient and responsive.

What are the benefits of using a brushless, permanent magnet design?

Brushless motors typically have lower maintenance requirements compared to other designs, which in turn means extended lifespans. This is one of the main reasons why STOBER selected to use this design in our high-performance servo motor lineup. In addition, having permanent magnets means these motors can deliver high torque density, lower heat generation and improved energy efficiency. Their smaller size also makes them ideal for compact installations.

What does “low torque ripple” mean and why does it matter?

Torque ripple refers to any fluctuations in torque during rotation, which can disrupt smooth operation of the motor if it is severe enough. STOBER’s designs feature optimized rotor and stator design, which cuts down on torque ripple and ensures better accuracy and smoother motion. This is especially beneficial in high-precision industries like semiconductor manufacturing or automated inspection systems.

Can STOBER customize synchronous servo motors for unique applications?

Absolutely — any time the off-the-shelf components don’t provide the perfect fit, we can provide custom motor solutions that will. Some examples of typical modifications we can make include shaft variations, thermal protection, mounting designs and integrated feedback. We work closely with customers in demanding sectors including aerospace, food processing and packaging automation, meaning we have the experience and expertise to help you customize your motors to meet your exact specifications.

What industries use STOBER’s synchronous servo motors?

Some of the many industries that use STOBER synchronous AC servo motors and why include:

- Aerospace: These provide a compact motor footprint and reliable torque.

- Automotive: Automakers value their dynamic performance under variable load conditions.

- Food and Beverage: These motors are washdown-compatible and come in IP-rated options.

- Material Handling: The responsive acceleration and deceleration of these motors make them perfect for conveyors and robotic arms.

- General Automation: Our servo motors offer precision motion control and efficiency for automated systems.

How does STOBER’s configurator help select the right motor?

The STOBER Configurator is a tool designed to help you simplify the process of choosing the right option from our inventory of motors, gearboxes and mounting configurations. Just enter the torque, speed and dimensions you need to meet and this tools narrows down your choices from our available options. This is especially useful for engineers during the design and procurement phases.

What feedback options are available for STOBER synchronous servo motors?

One of the most important features of STOBER’s synchronous servo motors for automation is the fact that they support various encoder types including absolute, incremental and resolver feedback. These feedback devices help enable precise speed control, positioning and torque control in closed-loop synchronous motor systems. Your selection will depend on the application’s accuracy and communication protocol requirements such as SSI, BiSS or EnDAT. Our experts are here to help you determine which feedback options make the most sense for your motor and your application.

How compact are STOBER’s synchronous servo motors compared to traditional designs?

STOBER’s EZ series is engineered with high power density, allowing it to deliver powerful performance in a relatively small footprint. Their compact size means these servo motors can enable space-saving machine layouts, lighter assemblies and greater design flexibility. Many of our customers find this especially useful in robotic arms, gantry systems and confined enclosures.

Are STOBER synchronous servo motors suitable for harsh or washdown environments?

STOBER’s lineup of synchronous servo motors includes IP-rated options as well as stainless steel and coated models. Along with options that can withstand aggressive cleaning agents and moisture, these motors are ideally suited for washdown and outdoor use. These are most commonly used in food processing, beverage bottling and pharmaceutical packaging applications where hygiene and corrosion resistance are critical.

How does STOBER support integration of servo motors into existing systems?

Our options are compatible with a wide range of motion controllers and servo drives. Beyond that, they feature flexible shaft, flange and mounting configurations to simplify integration. On top of that, STOBER’s application engineers can assist you with performance matching, CAD models and custom options to make the process even easier.

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Catalog Synchronous servo geared motors EZ | 15 | 442437 | 2025 05 | EN | 25.03 MB |

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Spare parts list Asynchronous motor basic design with brake | 00 | 443522 | 2025 07 | EN | 2.10 MB |

| Commissioning instruction EZ motors on B&R drive controllers | 01 | 443184 | 2023 04 | EN | 1.34 MB |

| Data Sheet EZ302 | 1 | 442831 | 2021 09 | EN | 387.03 KB |

| Data Sheet EZ303 | 1 | 442832 | 2021 09 | EN | 387.91 KB |

| Data Sheet EZ401 | 1 | 442833 | 2021 09 | EN | 566.16 KB |

| Data Sheet EZ402 | 1 | 442834 | 2021 09 | EN | 561.14 KB |

| Data Sheet EZ404 | 1 | 442835 | 2021 09 | EN | 560.45 KB |

| Data Sheet EZ501 | 1 | 442836 | 2021 09 | EN | 564.90 KB |

| Data Sheet EZ502 | 1 | 442837 | 2021 09 | EN | 560.37 KB |

| Data Sheet EZ503 | 1 | 442838 | 2021 09 | EN | 560.03 KB |

| Data Sheet EZ505 | 1 | 442839 | 2021 09 | EN | 558.53 KB |

| Data Sheet EZ702 | 1 | 442841 | 2021 09 | EN | 560.81 KB |

| Data Sheet EZ701 | 1 | 442840 | 2021 09 | EN | 560.03 KB |

| Data Sheet EZ703 | 1 | 442842 | 2021 09 | EN | 558.85 KB |

| Data Sheet EZ705 | 1 | 442843 | 2021 09 | EN | 558.41 KB |

| Data Sheet EZ802 | 1 | 442844 | 2021 09 | EN | 557.15 KB |

| Data Sheet EZ803 | 1 | 442845 | 2021 09 | EN | 547.29 KB |

| Data Sheet EZ805 | 1 | 442846 | 2021 09 | EN | 547.36 KB |

| Data Sheet EZ301 | 1 | 444283 | 2021 09 | EN | 373.89 KB |

STOBER’s Motors: The Range You Need

STOBER Configurator