Technology never really stands still, and new advancements are being made all the time. Even if they only represent incremental improvements, these changes bring even more value to industrial equipment and make it even more capable of meeting the ever-increasing demand of global markets. Industrial gearboxes are no exception to this rule, and recent developments have brought them to new heights.

Engineers and OEMs need to keep themselves informed of these new gearbox technologies if they want to keep up with the increasingly elevated performance expectations throughout the manufacturing, packaging and robotics sectors. With trends such as automation, miniaturization, energy-efficiency and Industry 4.0 exerting their influence over the marketplace, it’s no wonder industrial gearboxes continue to evolve and change. What follows is a brief overview of some of the latest gearbox technology to make its mark on the industry today.

Precision engineering and servo gearbox integration

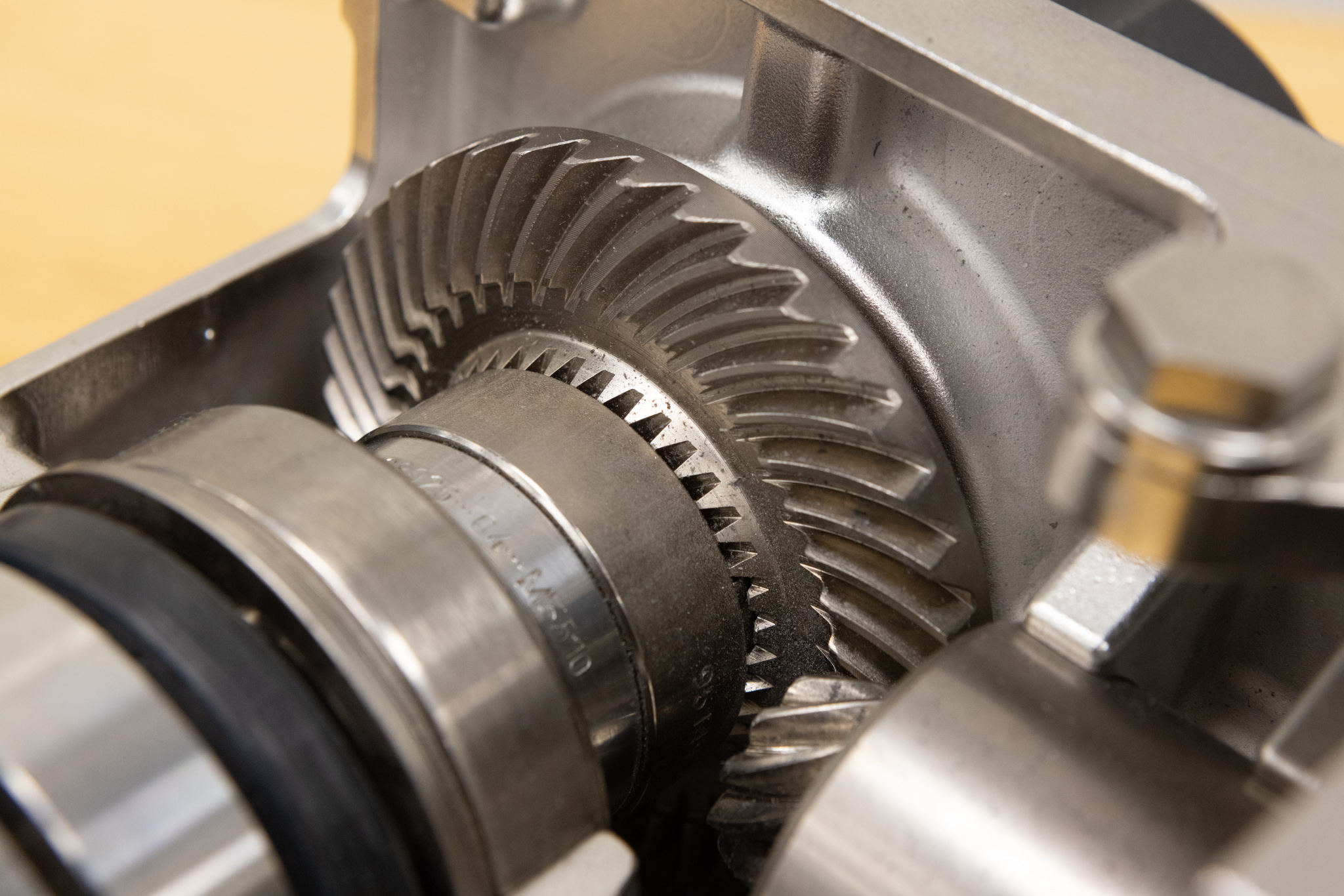

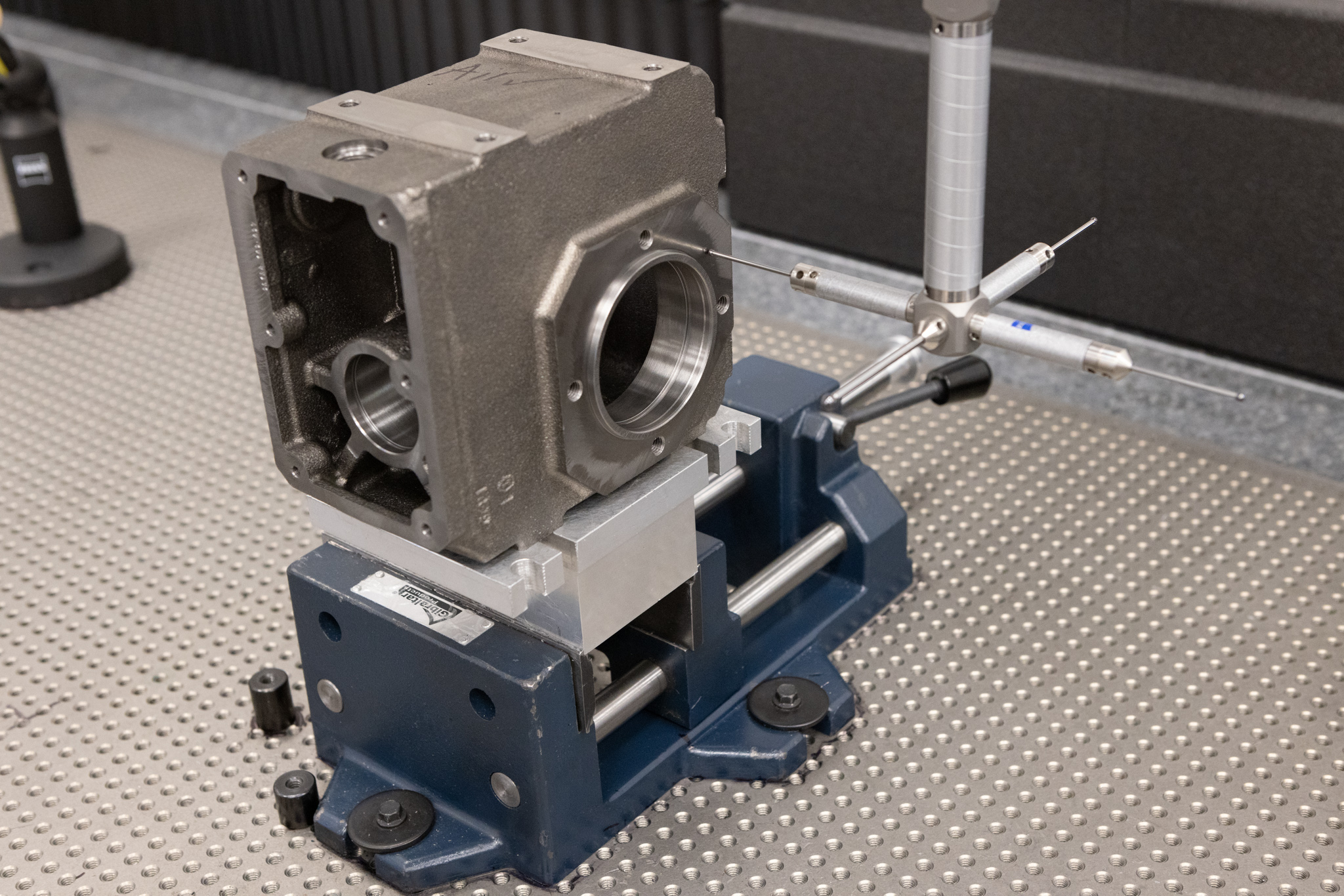

As the demands placed on them become more intense, there’s a greater need for industrial gearboxes that deliver higher performance and more precise control. Some of the key developments in this regard include optimized gear tooth geometry, reduced backlash and higher torsional stiffness. At the same time, integrating gearboxes with servo systems also serves to improve motion profiles, synchronization and responsiveness in automation.

STOBER leads the way in the industry with our range of high-precision planetary and right-angle servo gearboxes that incorporates the latest designs. In addition, the modularity of our offerings makes them easy to integrate with most major servo brands for exceptional performance.

Advanced materials, coatings, and IP protection

Industrial equipment has to be able to stand up to some harsh conditions, and industrial gearboxes are being fortified to survive and thrive thanks to some advanced materials. With case-hardened steel, heat-treated components, and corrosion-resistant finishes, modern gearboxes are being built to specifications that weren’t possible in years past. This helps ensure a longer lifespan for machinery and higher productivity. Their use in sanitary environments also means compatibility with food-safe lubricants and non-porous surfaces are essential, as well.

Our IP-rated gearboxes include fully stainless steel models made specifically for use in harsh washdown conditions. STOBER is known for building the world’s toughest and most advanced industrial gearboxes, and the state-of-the-art protective coatings and sealing systems we employ help reduce maintenance needs and extend the service life of your equipment.

Smart gearbox technology and digital monitoring integration

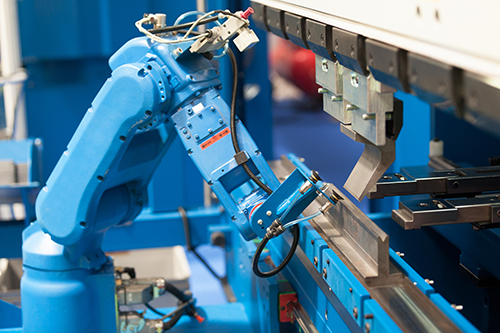

Virtually every aspect of the modern manufacturing environment has been connected to smart technology in one form or another. It’s a core element of Industry 4.0 that equipment be linked to each other as well as sensors that can detect specific environmental conditions as well as provide real-time information concerning asset health.

Gearboxes equipped with sensors can detect excessive vibration or temperature along with checking for oil quality and load conditions. This gives technicians a wealth of information they can use to detect issues before they cause failures and optimize their maintenance schedules. With detailed information about the condition of their gearboxes, operators can keep machinery online for as long as possible and avoid unplanned downtime that can hurt productivity.

STOBER’s gearboxes support most Industrial Internet of Things (IIoT) frameworks. In addition, they also include SCADA/PLC integrations to support digital monitoring. This can be especially helpful in high-throughput operations, where digital feedback loops can enhance efficiency.

Accelerated lead times and custom engineering support

Gearboxes are often designed and engineered for very specific functions, meaning it’s important to work with a provider who has the ability to turn around designs as quickly and accurately as possible. Being able to bring products to market on an accelerated schedule is a major competitive advantage for most companies, and this makes custom engineering support so valuable.

As a leader in industrial gearbox innovation, STOBER is here to provide our customers with the fast, responsive services they need to compete. Our collaborative engineering team works closely with customers to ensure the gearbox solutions we provide will align with all the application’s specific requirements. We’re also on the cutting edge of the industry when it comes to our quick-turn production capabilities, which ensure our customers receive their new components in a fraction of the time it would take other gearbox companies to deliver. In addition, our 24/7 support and configurator tool give peace of mind that our solutions will be as effective and dependable as they can be.

No matter the application, STOBER’s lineup of gearbox products include the innovative features and forward-thinking designs needed to keep up with the speed of today’s markets. If you want to learn more about what makes STOBER the leader in the industry, reach out and get in touch with one of our representatives today to start a conversation about your needs. Be sure you’ll have the proper alignment so your gearboxes will deliver the power and performance you need.

To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

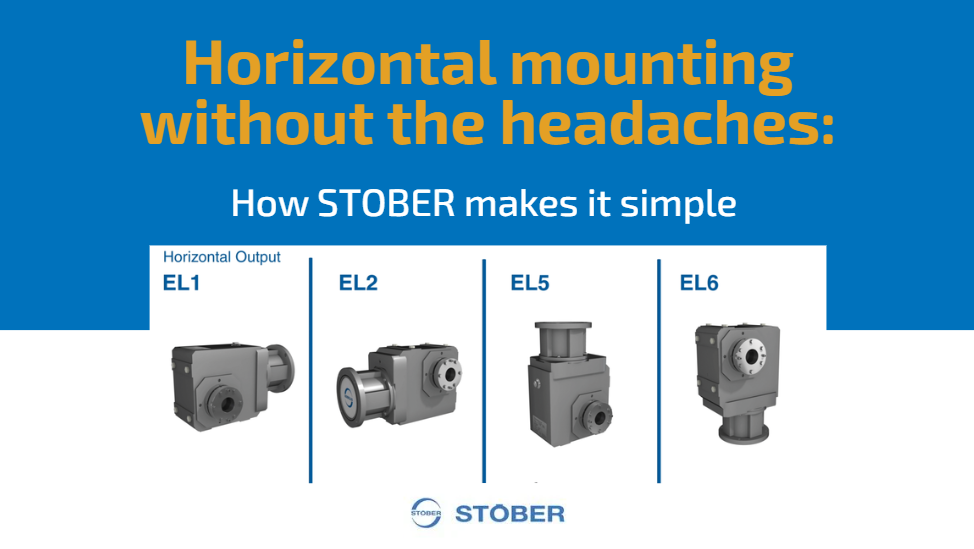

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs