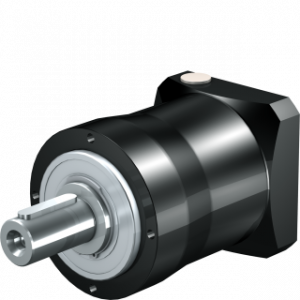

Learn how a planetary gearbox works, its components, and why this compact, high-torque design delivers exceptional performance and reliability across industrial applications.

A planetary gearbox is a compact, efficient mechanical system used to transmit torque and control speed. It consists of three main components: the sun gear, planet gears, and ring gear, all held together by a carrier. This unique configuration enables precise motion control and high torque density, making planetary gearboxes essential in industries like automotive, robotics, and industrial machinery.

Understanding how a planetary gearbox works begins with its core principle: power transmission through multiple gear engagements. This design evenly distributes load and reduces wear, resulting in superior durability and efficiency compared to other gearbox types. Industries requiring precision, such as robotics and automotive, benefit greatly from these systems. Explore our products for the best planetary gear set solutions for your needs.

Components of a planetary gearbox

The performance of a planetary gearbox relies on its expertly designed components:

- Sun Gear: The central gear that drives the system, providing input power.

- Planet Gears: Surrounding the sun gear, these gears orbit around it and engage with the ring gear to transfer torque.

- Ring Gear: Encasing the planet gears, it facilitates torque distribution to the output shaft.

- Carrier: Holds the planet gears in place and ensures smooth motion transfer to the output.

Each part of the planetary gear set—sun gear, planet gears, ring gear, and the planet carrier—works together as a planetary carrier within a highly efficient planetary gear train. This interconnected gear train system enables precise load distribution and consistent torque transfer across all contact points.

How does a planetary gearbox work?

The planetary gear system achieves high torque and low speed through its innovative design. Power flows from the input shaft to the sun gear, causing the planet gears to orbit and engage with the stationary ring gear. This simultaneous interaction creates multiple points of contact, distributing loads efficiently and minimizing energy loss.

This gear ratio optimization makes planetary gearboxes ideal for applications requiring durability and heavy-duty performance, such as industrial machinery, wind turbines, and automotive systems. In simple terms, this system demonstrates how a planetary gearbox works: the sun gear serves as the input, the planet gears rotate within the ring gear, and the carrier delivers the output. This arrangement allows for high torque transmission in a compact, balanced configuration that maximizes load sharing in gear systems.

Planetary gearbox efficiency & performance factors

Planetary gearboxes are valued for their exceptional efficiency—often achieving performance levels of 95% or higher. This high efficiency results from multiple gear engagements that share the load, reducing friction and slippage.

Torque density is another defining factor. Even in a compact gear design, planetary gearboxes can handle significantly higher torque loads compared to spur or worm gear designs. Because power is distributed across several gears simultaneously, heat generation is minimized, extending lubricant and component lifespan.

When comparing planetary gearboxes to other types, worm gearboxes lose more energy due to friction, while spur gearboxes are less compact and lack comparable torque density. In contrast, planetary systems maintain superior torque output and longevity.

Efficiency in planetary gearboxes impacts more than performance—it influences energy costs, machine uptime, and overall system reliability. Engineers can also pursue gear efficiency improvement by optimizing lubrication, minimizing backlash, and ensuring balanced load paths across the planetary gear train.

Learn more about our planetary gearboxes for the automation industry.

Types of planetary gearboxes

Planetary gearboxes are versatile, with several types designed for specific needs:

- Single-Stage Gearboxes: Suitable for moderate torque and speed adjustments, often used in compact applications.

- Multi-Stage Gearboxes: Provide higher torque and greater speed reductions, ideal for demanding industrial environments.

- Compact Designs: Lightweight and space-efficient, these are perfect for robotics and electric vehicles where size and weight are critical.

Each type offers unique advantages, allowing users to select the best planetary gearbox for their application.

Planetary gearbox maintenance & lifespan

To maintain peak efficiency and extend the lifespan of a planetary gearbox, regular maintenance is essential. Recommended practices include:

- Performing routine oil changes using OEM-specified lubricants.

- Conducting oil analysis to detect contamination or early wear.

- Inspecting seals and bearings for leaks or vibration irregularities.

- Monitoring operating temperature to prevent overheating under heavy load conditions.

Under proper care, planetary gearboxes can last more than 20 years in industrial use. Poor maintenance, however, can reduce lifespan significantly due to wear on seals, bearings, and gear teeth.

STOBER planetary gearboxes incorporate precision machining, advanced sealing, and efficient lubrication systems designed to extend service life and reduce downtime.

For more insights on keeping systems running efficiently, read why maintenance of gearboxes is critical for industrial performance. Ultimately, preventive maintenance not only lowers total cost of ownership but also improves reliability and operational continuity across production environments.

Advantages of planetary gearboxes

Planetary gearboxes offer several key benefits:

- High Torque Density: Compact size delivers powerful performance.

- Compact Design: Fits into tight spaces without compromising efficiency.

- Load Distribution: Shares forces across multiple gears, reducing wear and enhancing durability.

- Versatility: Adapts to various industries, from automotive to industrial machinery.

These advantages make planetary gearboxes a preferred choice for precision and reliability.

Applications of planetary gearboxes

Planetary gearboxes are indispensable in many industries:

- Automotive: Ensures smooth, reliable operation in automatic transmissions.

- Robotics: Provides compact and precise motion control for advanced robotics.

- Industrial Machinery: Handles heavy loads in conveyors, mixers, and cranes.

- Wind Turbines: Facilitates efficient energy transfer in renewable energy systems.

Explored our industries served and applications for planetary gearboxes to learn more.

Expanded applications of planetary gearboxes

Beyond traditional uses, planetary gearboxes power innovation in several cutting-edge industries:

- Aerospace: Used in actuation systems, satellite controls, and drones where reliability and torque precision are essential.

- Medical Technology: Powering surgical robots, imaging systems, and precision instruments.

- Packaging & Material Handling: Ensuring consistent torque delivery in conveyors, palletizers, and labeling systems.

- Renewable Energy: Supporting solar tracking mechanisms and hydroelectric drives for energy efficiency.

- Machine Tools: Enabling high accuracy in CNC milling, cutting, and printing applications.

From microscale robotics to large-scale energy systems, the planetary gear system adapts effortlessly to deliver stability, precision, and endurance.

Choosing the right planetary gearbox

Selecting the right planetary gearbox involves evaluating:

- Torque and speed requirements: Ensure the gearbox matches the application’s specifications.

- Size and environment: Choose a design that fits within space constraints and withstands environmental conditions.

- Durability and materials: Opt for high-quality materials to ensure long-term performance.

At STOBER, we offer expert guidance to help you balance initial investment with long-term reliability for optimized performance.

Key specifications to consider when buying a planetary gearbox

Engineers and procurement professionals should assess several critical specifications before selecting a planetary gearbox:

- Gear Ratio Range: Determines torque and speed trade-offs based on application.

- Backlash Levels: Low backlash is crucial for robotics, CNC, and precision automation.

- Torque Ratings: Evaluate continuous and peak torque to ensure safe load handling.

- Load Capacities: Review radial and axial load tolerance for durability under pressure.

- Noise Levels: Important for sensitive environments such as medical or packaging facilities.

- Mounting Configurations: Choose between inline or right-angle planetary designs for layout flexibility.

Environmental factors like temperature, duty cycle, and contamination also influence performance and longevity. Avoid selecting gearboxes purely on price—neglecting backlash or future scalability can lead to inefficiency and costly retrofits.

STOBER’s modular planetary gearbox systems provide tailored torque, mounting, and size options to meet the most demanding performance criteria. Explore our inline servo gearboxes for high-precision industrial motion control.

The future of efficiency: planetary gearboxes

Planetary gearboxes blend efficiency, durability, and compactness to excel in various applications. Their advanced design is essential for industries like robotics, automotive, and heavy machinery. As technology advances, planetary gearboxes will continue to drive innovation and operational excellence.

Future trends in planetary gearbox design include material science advancements, hybrid drive integration, and AI-supported predictive maintenance—further improving reliability and lifecycle performance.

STOBER is a trusted provider of cutting-edge planetary gearboxes, offering customized solutions tailored to meet modern industry demands. Whether you need precision motion control or heavy-duty torque transmission, we deliver the reliability and performance you need.

When it comes to servo inline gearboxes, STOBER’s products are unrivaled in precision and options. STOBER’s planetary products feature unparalleled precision, power, and flexibility. Plus, you can choose from several bearing options to handle radial or axial loads, optimizing your machine design. Both the P and PH gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter. These units are assembled in our Maysville, Ky. facility, shipped in one day, and come with a 5-year warranty.

Ready to optimize your motion system? Contact STOBER today to explore our full line of planetary gearboxes, servo gear systems, and customized motion solutions.

Learn more about planetary options from STOBER by clicking the link below or contact us at (888) 786-2371 or email sales@www.stober.com.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025