Geared motors for washdown applications

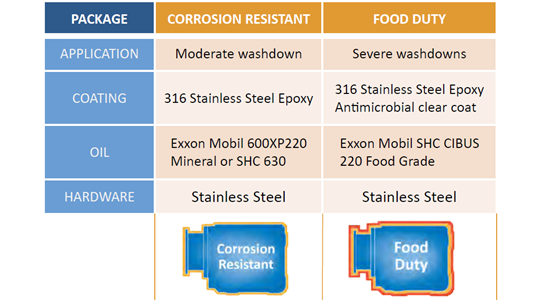

With food duty or corrosion-resistant options, STOBER is proud to offer sanitary geared motors for washdown applications in a variety of manufacturing environments and industries.

Water ingress is one of the leading causes of equipment failure in industrial washdown environments, but it’s not an issue with STOBER’s food-duty geared motors. The ingress protection packages from STOBER feature stainless steel hardware, special lubrication, and application-specific coatings. In addition, an option for water ingress protection up to IP66 for geared motors is available.

With STOBER’s wide range of stainless-steel geared motors, food- duty or corrosion-resistant specs are available on six different geared motor series, including inline or right-angle options. If an inline flange mount option is needed, we can provide our PH series with washdown paint and lubrication. STOBER’s geared motors and input adapters share the same flanges, so there’s always a perfect fit to the gearbox, which is key in preventing premature failure.

When you choose STOBER corrosion-resistant geared motors, you also reap the benefits that come with them, including a 2-year warranty, 24/7/365 support, and multiple third-party integration options for single and dual-cable solutions, including Rockwell DSL.

STOBER‘s washdown servo motors, including the cLEAN system, feature all of these advantages and much more. With the largest breadth of product and the most compact washdown geared motors on the market, STOBER is ready to configure your next solution.

Frequently Asked Questions

What makes a geared motor suitable for washdown applications?

Our systems are ideal for frequent cleaning cycles found in food and beverage, packaging, and processing lines. This is due to their sealed motor housing, electropolished housings, food-grade lubrication, and IP66/IP69K sealing systems. These features eliminate oil leaks, rust, and water ingress that cause failures in typical geared motors.

How do STOBER’s food-duty geared motors meet hygiene and safety standards?

Our food processing equipment motors are designed for food-grade compliance and long-term reliability in washdown conditions thanks to their food-duty coating, antimicrobial clear coat, and CIBUS 220 synthetic lubricant. Not only do these features reduce contamination risks, but they also reduce downtime and maintenance needs.

Can STOBER geared motors be configured for specific washdown requirements?

We offer a range of modular configurations, including inline, right-angle, or offset designs. Other options include coatings, mounting styles, and motor adapters. This means our maintenance-free geared motors can fit into just about any environmental conditions while also being compatible with a wide range of motor types.

Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025  The Christmas miracle: How STOBER delivered when it mattered most

The Christmas miracle: How STOBER delivered when it mattered most