As 2025 comes to a close, we’re looking back at the insights that mattered most to you. From maintenance tips to success stories, these blogs sparked conversations, solved challenges, and helped drive innovation across the industry. Here are the top STOBER blogs of the year—your favorites, all in one place!

5. cLEAN Drive: Easy to install, easy to use

STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

3. cLEAN up your act with STOBER’s cLEAN System

What could contamination in your plant cost? Could oil leaks ruin your production? Could bacteria growing on your equipment compromise your product’s integrity?

4. STOBER announces new ZS rack

While rack and pinion products are not new for STOBER, the new ZS Rack that launched this week elevates STOBER’s rack and pinion offerings. The ZS Rack is made to STOBER specifications and provides the best solutions for customers.

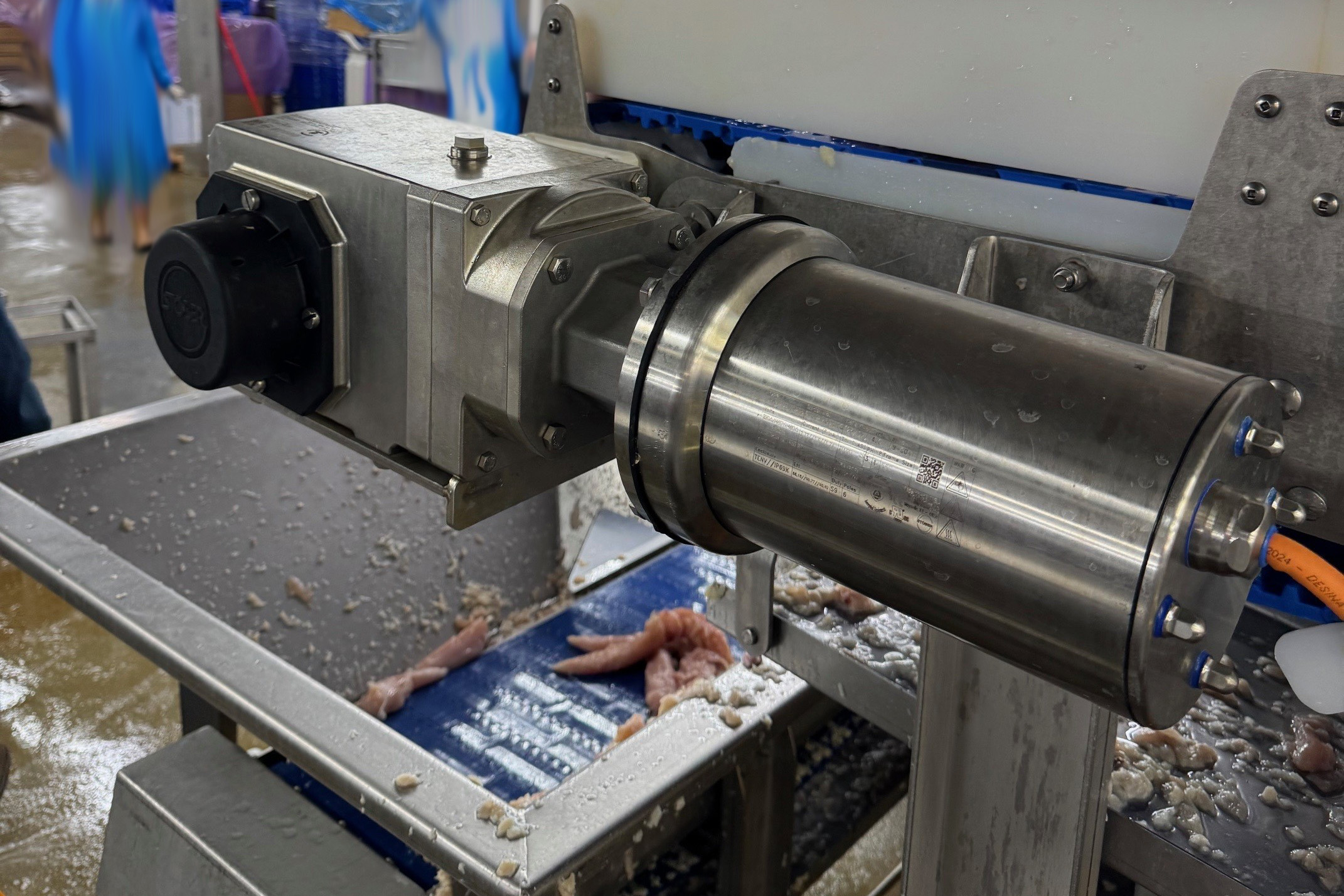

2. STOBER food-duty gearboxes and geared motors use antimicrobial coating

STOBER’s food-duty products thrive in harsh washdown and severely wet applications thanks to their featured antimicrobial coating. STOBER’s food-duty package includes stainless steel hardware and plastic covers, multilayered 316 stainless steel epoxy coating, antimicrobial clear top coat, and Exxon Mobil SHC CIBUS 220 food grade oil.

1. Customer success: Boosting uptime with STOBER food-duty solutions

A leading poultry processor in the mid-Atlantic was facing repeated failures and costly downtime on a critical section of its production line. Uptime was being halted by gearboxes on their conveyor systems that couldn’t withstand the demands of washdown conditions, high torque requirements, and continuous operation. Frequent breakdowns led to production delays, increased maintenance costs, and pressure on plant performance.

Thank you for making 2025 an incredible year! These top blogs reflect the conversations and challenges that matter most to you. As we head into 2026, we’re committed to delivering even more insights, tips, and success stories to help you achieve your goals.

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

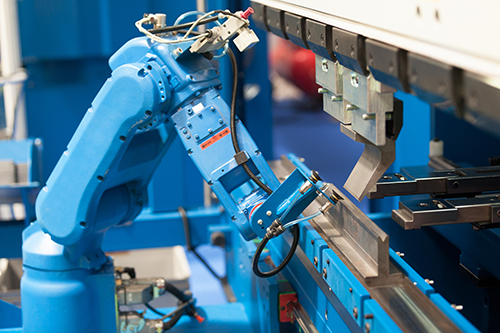

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

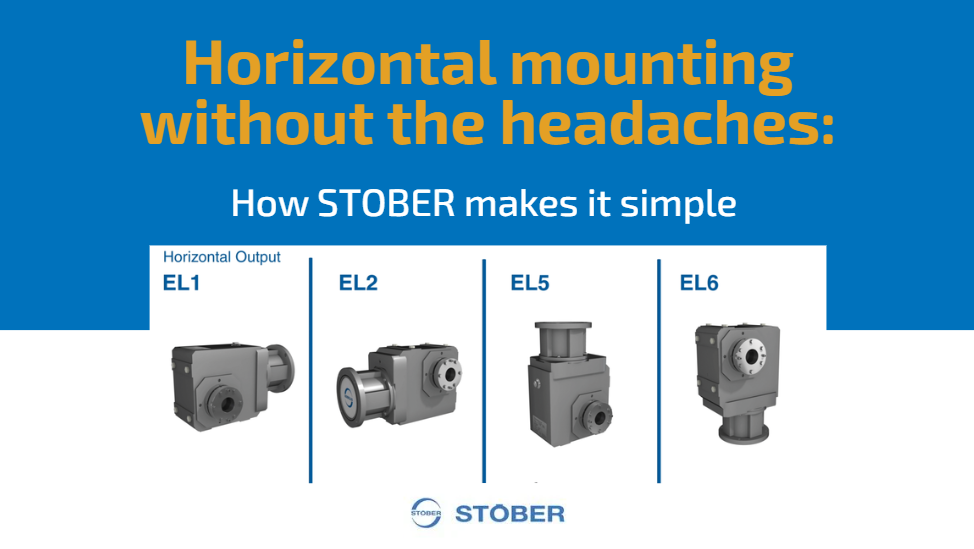

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs