When choosing a servo motor, making the right selection isn’t just about matching specs on a data sheet—it’s about finding the perfect fit for your application, environment, and performance goals. Whether you’re engineering an automated production line, designing precision robotics, or upgrading existing equipment, the wrong motor can mean reduced efficiency, increased downtime, and higher operating costs.

At STOBER Drives, we help customers navigate these decisions every day. Here are four critical factors to consider when selecting a high-performance servo motor:

1. Understand your duty cycle

The duty cycle defines how long and how often your motor runs under load. This affects both the thermal and mechanical load the motor must handle. Servo motors operating under continuous loads will require different cooling and sizing strategies compared to those with intermittent use.

Key considerations:

- Continuous Duty (S1): Requires motors designed for sustained operation without overheating.

- Intermittent Duty (S5-S8): May allow for smaller or more efficient motor selection, but must account for peak loads and dwell time.

STOBER tip: Use our Servo Motor Configurator to simulate duty cycles and get motor recommendations based on thermal modeling and application data.

2. Assess your environment

Where and how the motor will be used can dramatically influence performance and longevity. Harsh environments require special attention to motor sealing, material selection, and ingress protection (IP) ratings.

Environmental factors include:

- Dust, moisture, or washdown conditions

- High or low ambient temperatures

- Food-grade or cleanroom applications

STOBER advantage: Our stainless steel servo motors and cLEAN System solutions are ideal for hygienic and washdown environments—especially in food, beverage, and pharmaceutical applications.

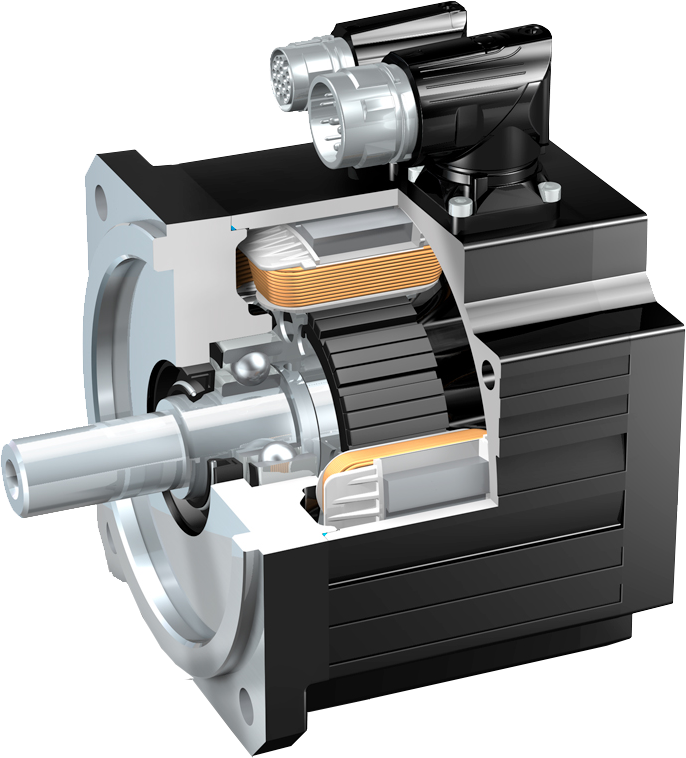

3. Calculate required torque

Torque is the force that turns your load—and if it’s undersized or overestimated, you risk inefficiency or mechanical failure. Evaluate both continuous torque and peak torque requirements based on your application’s load characteristics.

Common torque considerations:

- Acceleration/deceleration requirements

- Load inertia

- Holding or braking torque needs

STOBER engineering support: We provide tools and expert guidance to accurately calculate torque profiles and select the ideal gearmotor and drive combination.

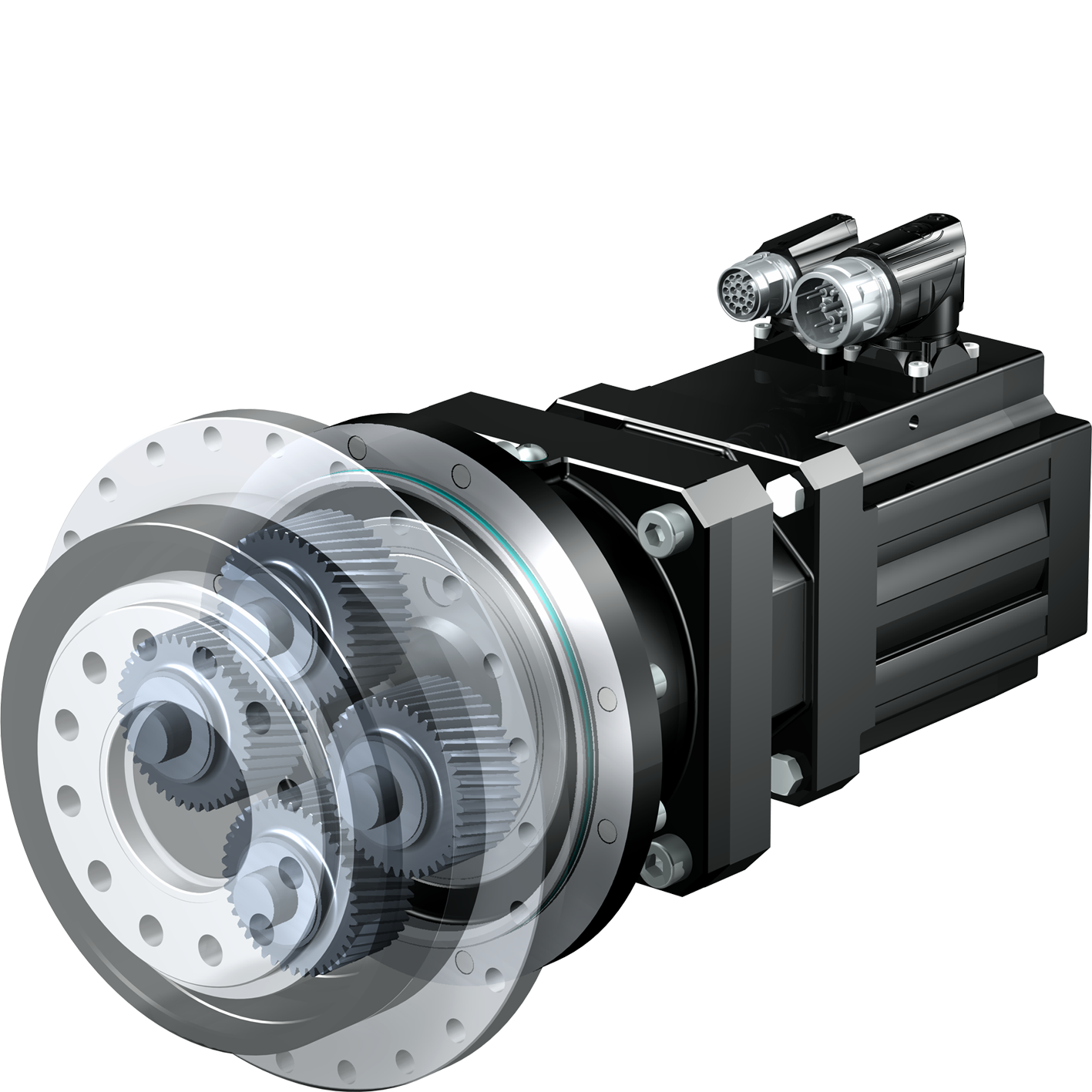

4. Match the right speed

Servo motors are designed for dynamic performance, but matching motor speed to your machine’s needs is crucial. Speed and torque often trade off, so choosing the right combination—possibly with a gear reducer—can optimize system performance.

Think about:

- Target operating speed range

- Required acceleration times

- Mechanical limitations of the driven system

STOBER gear solutions: Our planetary and helical gear units seamlessly integrate with STOBER servo motors, offering compact solutions for high-torque, low-speed applications.

Selecting the right servo motor is a strategic engineering decision—and STOBER makes it easier. With our wide range of modular drive components, expert support, and industry-specific solutions, you can confidently match the motor to your performance, environmental, and operational needs.

Need help sizing your motor?

Try the STOBER Configurator or get in touch with our team for personalized recommendations. To discover the right solutions for your needs, explore products now or contact us at (888) 786-2371 or email sales@stober.com.

What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025