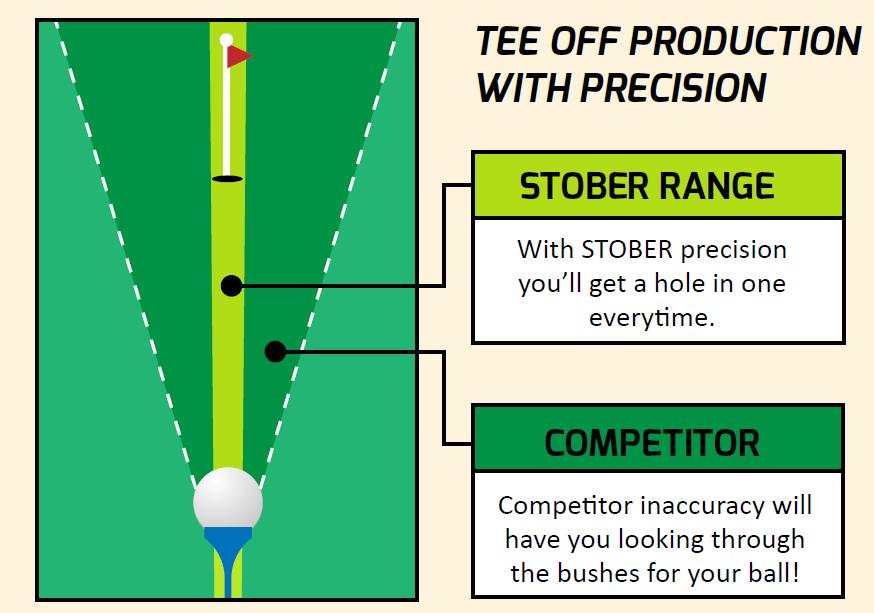

In golf, the smallest adjustment can make the biggest difference — a fraction of a degree in your swing path can be the difference between landing on the green or in the rough. The same is true in high-performance machinery. Even the slightest backlash in a gearbox can throw your process off target, affecting accuracy, speed, and consistency.

At STOBER, we believe precision should be as dependable as a well-practiced swing — and thanks to our reduced backlash gear units assembled in Maysville, Ky., you can count on hitting the sweet spot every time.

The hidden power of precision

True performance isn’t just about specs on paper — it’s about how every component in your system works together to deliver consistent, repeatable results. Reduced backlash gear units are a perfect example:

- Minimal clearance, maximum accuracy – By reducing the gap between gear teeth, we ensure your motion stays true from start to finish.

- Smooth, controlled motion – Less vibration means better product quality and less wear on your machine.

- Higher torque capacity – Handle demanding loads without sacrificing precision.

When your equipment moves exactly as intended, cycle after cycle, you unlock the hidden potential in your production line — higher throughput, fewer rejects, and greater confidence in every run.

Built for demanding applications

From high-speed label printing to complex multi-axis machining, reduced backlash gear units keep your process on track. Industries that benefit include:

- Converting & printing – Perfect label placement and print registration at high speeds.

- Machine tools – Accurate milling, drilling, and grinding without drift.

- Metal forming – Consistent stamping, bending, and pressing operations.

And because STOBER gear units have no thermal deviation, you won’t need to adjust parameters to compensate for heat expansion — a common issue with competitor products. Reduced backlash options provide smoothness of motion through precise gearing and offer up to 20 percent higher torque capacity–they’re the most precise solution on the market! Capable of backlash as low as 1 arc min, reduced backlash option is the ultimate precision solution.

Assembled in the USA, delivered fast

Precision is powerful — but only if you can get it when you need it. STOBER reduced backlash gear units and geared motors are proudly assembled in Maysville, Kentucky. That means:

- Rapid turnaround – Custom builds shipped in days, not months.

- Local expertise – Our team understands your application and can configure the perfect solution.

- Consistent quality – Every unit is built to the same exacting standards, no matter the configuration.

Whether you need a gearbox, rack & pinion, or geared motor configuration, we can deliver it quickly — without compromising on precision.

The STOBER advantage

When you choose STOBER, you’re getting more than a gearbox — you’re getting:

- Unmatched precision – Accuracy down to 1 arcmin.

- Proven reliability – Built to perform in the toughest environments.

- Fast delivery – Keep your projects moving without long waits.

Ready to drive your precision further? Start building your reduced backlash gearbox or geared motor today with our online configurator, or contact our team for expert guidance at (888) 786-2371 or email sales@stober.com. Still researching? Watch the YouTube video at the link below to learn more:

Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory  Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025  The Christmas miracle: How STOBER delivered when it mattered most

The Christmas miracle: How STOBER delivered when it mattered most