Prevent premature gearbox failure with one simple trick—eliminating water or chemical ingress in your gearbox! Read more to learn how.

To protect against internal moisture buildup, many NEMA wash–down motors have weep holes in the mounting face. But when a motor is in a wash–down environment, those weep holes become a liability.

Common causes of gearbox water ingress

Understanding what causes water ingress is the best way to prevent failures in washdown environments. Gearbox water ingress typically occurs through predictable pathways that develop during operation and sanitation cycles; the most common entry point is the weep holes found on many NEMA washdown motors. While intended for condensation release, these openings often undermine waterproof industrial motors by allowing moisture to flow directly toward the gearbox. When these lack a waterproof motor housing or sealed motor adapter, intrusion becomes even more likely.

Other vulnerable areas include shaft seals, breather vents and gasketed joints. While these components protect the drive system during operation, they can become weak points during washdowns. High-pressure spray in washdown applications can overwhelm small imperfections, forcing water through seals and gaps. Without gearbox contamination prevention, moisture intrusion becomes an issue that impacts lubrication and internal wear.

Temperature fluctuations between hot sanitation cycles and cooler production shifts can also produce internal condensation. Plus, chemical exposure from acids, alkalis and detergents accelerates seal deterioration, making it harder for any gearbox seal to maintain long-term integrity. Improper installation, including misalignment or torque imbalance, creates additional gaps that compromise a sealed gearbox design.

If left unaddressed, these ingress pathways contribute to corrosion, downtime and mechanical failure. In harsh washdown environments, corrosion prevention must be part of the design strategy to avoid costly repairs and protect productivity.

The gearbox can retain liquids when water and other cleaning chemicals enter through the weep holes. Over time, this will rust the internal components and affect the lubrication within the gearbox, which results in premature failure.

If the motor and gearbox are not suited for the environment or sanitation regimen, water can also enter through the output seals or the seal between the motor and the gearbox. In addition to the weep holes, breathers or vents can also allow for ingress.

Ingress can cause your company to lose thousands of dollars in downtime and productivity loss, so it’s important to take necessary precautions to prevent it. Here are some ways to do so:

- Use a gearbox that is IP69K Certified, which proves it can handle harsh washdowns. Confirm output seals and the seal between the motor and the gearbox are

isdesigned to withstand water or chemical intrusion.

- Assure the gearbox is completely sealed and does not have breathers or vents.

- Use a motor without exposed weep holes or plug the weep holes with different materials recommended by your local distributor.

These simple steps can prevent water ingress, save your company money, protect your gearbox warranty, and ensure the reliability of your gearbox.

Engineering solutions for water ingress prevention

Long-term water ingress prevention is dependent on engineering choices embedded in the gearbox itself. A crucial factor is the ingress protection rating, defined by internationally recognized ingress protection standards. Higher ratings such as IP66 and IP67 offer robust moisture resistance, but the gold standard in washdown environments is the IP69K gearbox, capable of withstanding high-pressure, high-temperature spray directed from multiple angles. These ratings are verified through ingress protection testing, confirming reliable performance in real operating conditions.

Material selection also influences durability. Corrosion resistant gearbox designs made from stainless steel with an electropolished surface reduce crevices where moisture can accumulate. Smooth passive surfaces enhance the performance of hygienic gearbox design, as well as the function of waterproof gearboxes used in food processing, packaging and chemical applications.

Structural configuration matters, too. A washdown rated gearbox often features a non-vented housing that prevents pressure-driven moisture intrusion during temperature changes. Precision-machined interfaces between motor and gearbox reduce intrusion points, while multi-lip or labyrinth seals boost resilience under harsh spray conditions and complement water resistant drive systems designed for daily sanitation cycles.

Together, these solutions deliver strong defense against ingress and support the performance expected from modern waterproof industrial motors and their integrated drive systems. For additional insight into washdown engineering, see how STOBER offers washdown options for geared motors.

Maintenance & inspection best practices for lasting water ingress prevention

Sustained water ingress prevention requires a structured approach to inspections and maintenance. During routine checks, technicians should look out for early signs of wear, such as oil discoloration, rust at shaft interfaces or residue buildup that may indicate moisture intrusion. Taking these steps also supports effective industrial seal maintenance, helping extend the life of every gearbox seal in the system.

Tools such as vibration analysis and infrared thermography also help identify anomalies caused by internal moisture or bearing degradation. Because contamination affects lubrication quality and internal temperature, monitoring viscosity and color changes plays a powerful part in ongoing corrosion prevention.

Seals, gaskets and plugs should be replaced at defined intervals rather than only when leaks appear; proactive replacement benefits the longevity of food-grade gearbox assemblies and minimizes the likelihood of ingress during sanitation cycles. Thorough documentation further aligns with reliability, warranty compliance and long-term drive performance across washdown environment protection plans.

With heightened sanitation performance, the STOBER cLEAN System is ideal for the food industry. Learn more about our solutions.

Choosing the right gearbox for harsh washdown environments

Selecting the right equipment is highly effective for minimizing gearbox water ingress in demanding environments. A standard unit often cannot withstand pressure and heat variations or chemical exposure during sanitation; in contrast, washdown rated gearbox designs are engineered with stainless steel housings, electropolished finishes and high-integrity seals that support hygienic processes and long-term durability.

Key features to prioritize? IP-rated enclosures, sealed motor interfaces and smooth surfaces suitable for direct contact with sanitizers. These all enhance reliability in environments requiring hygienic gearbox design and support performance in facilities with aggressive washdown schedules. Additional considerations are the use of food- grade gearbox lubricants and configurations that reduce exposure at shaft and adapter interfaces.

Selecting the correct drive package also helps support water resistant drive systems used across food production, packaging and chemical operations. To evaluate configurations and sealing technologies, engineers can explore the STOBER Configurator.

Consultation with application specialists can identify the right combination of materials and sealing strategies to support washdown durability, chemical resistance and long-term corrosion prevention.

STOBER has experience and expertise with eliminating premature gearbox failure. STOBER gearboxes are IP69K certified, last an average of 9.1 years in a harsh 24/7 environment, and come with a three-year warranty. Our highly-trained team would be glad to examine your environment and recommend a solution that will last.

Want to learn more about eliminating water ingress? Download our free guide below!

Selecting gearboxes for robotic & industrial automation systems

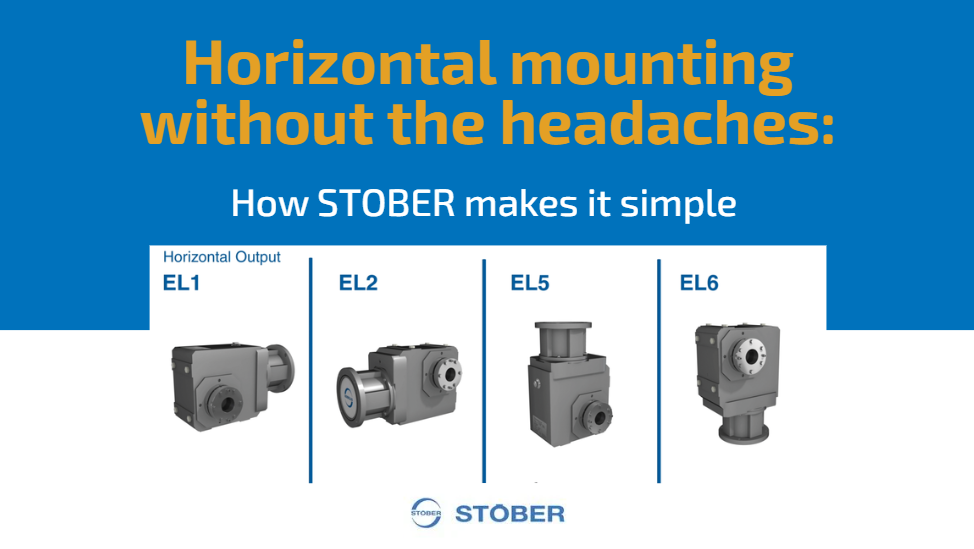

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices