MATERIAL HANDLING INDUSTRY

“Increase in demand means material handling equipment is needed now more than ever. How long is your lead time to get gearboxes and motors?”

Applications and Solutions in the Material Handling Industry

Application-specific material handling can be done through a variety of products, including drive conveyors, rack and pinion, ball screws, and dynamic safety brake options for vertical loads.

COMMON CHALLENGES AND PROBLEMS

1. Maintenance requirements

2. Harsh environments causing premature failure

3. Small envelope space for components

4. Pinch points causing safety hazards

Applications and Solutions in the Material Handling Industry

Application-specific material handling can be done through a variety of products, including drive conveyors, rack and pinion, ball screws, and dynamic safety brake options for vertical loads.

COMMON CHALLENGES AND PROBLEMS

1. Maintenance requirements

2. Harsh environments causing premature failure

3. Small envelope space for components

4. Pinch points causing safety hazards

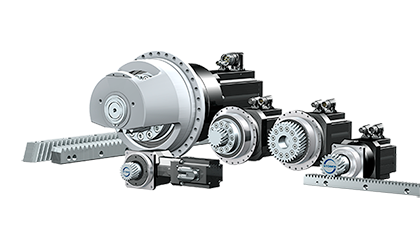

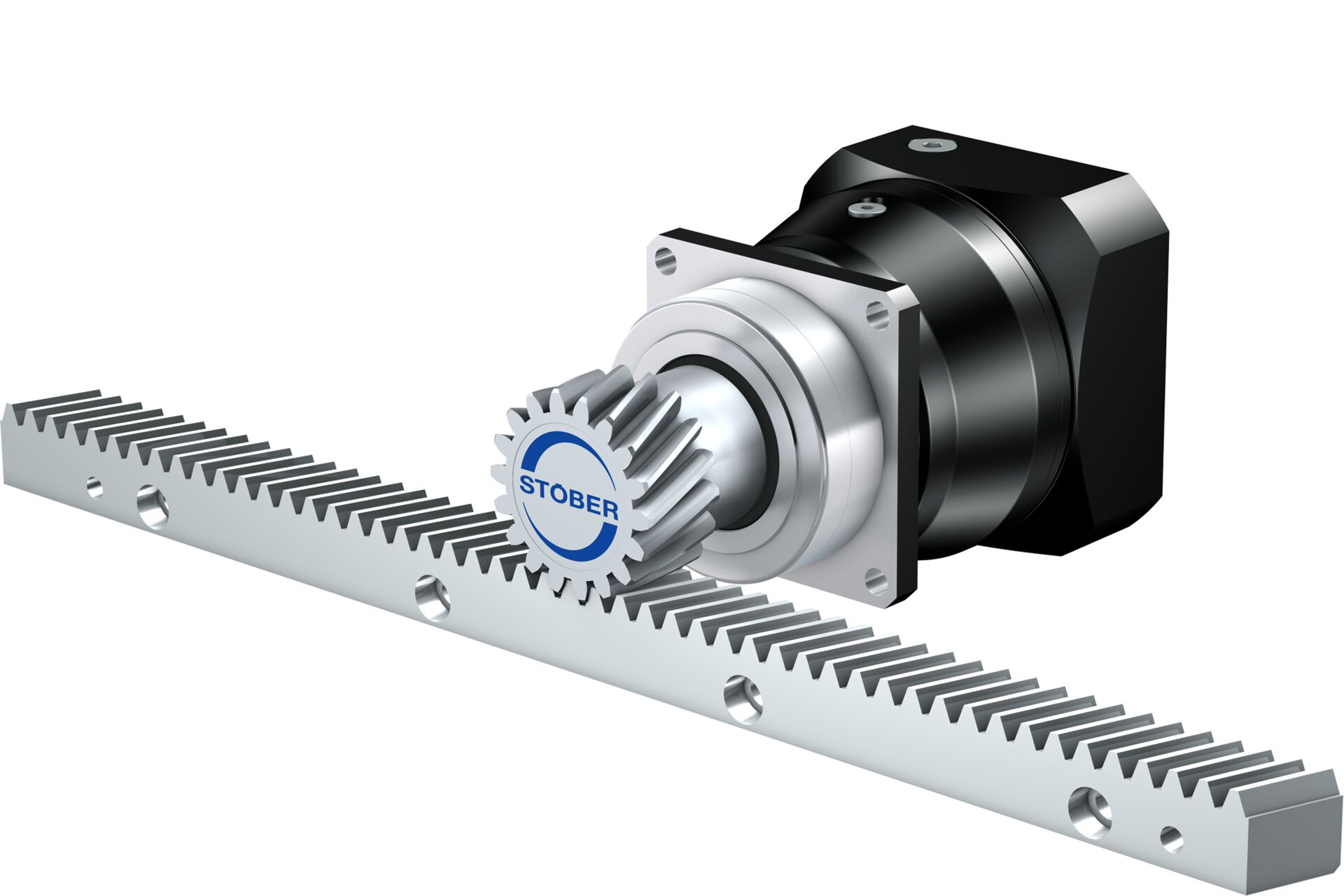

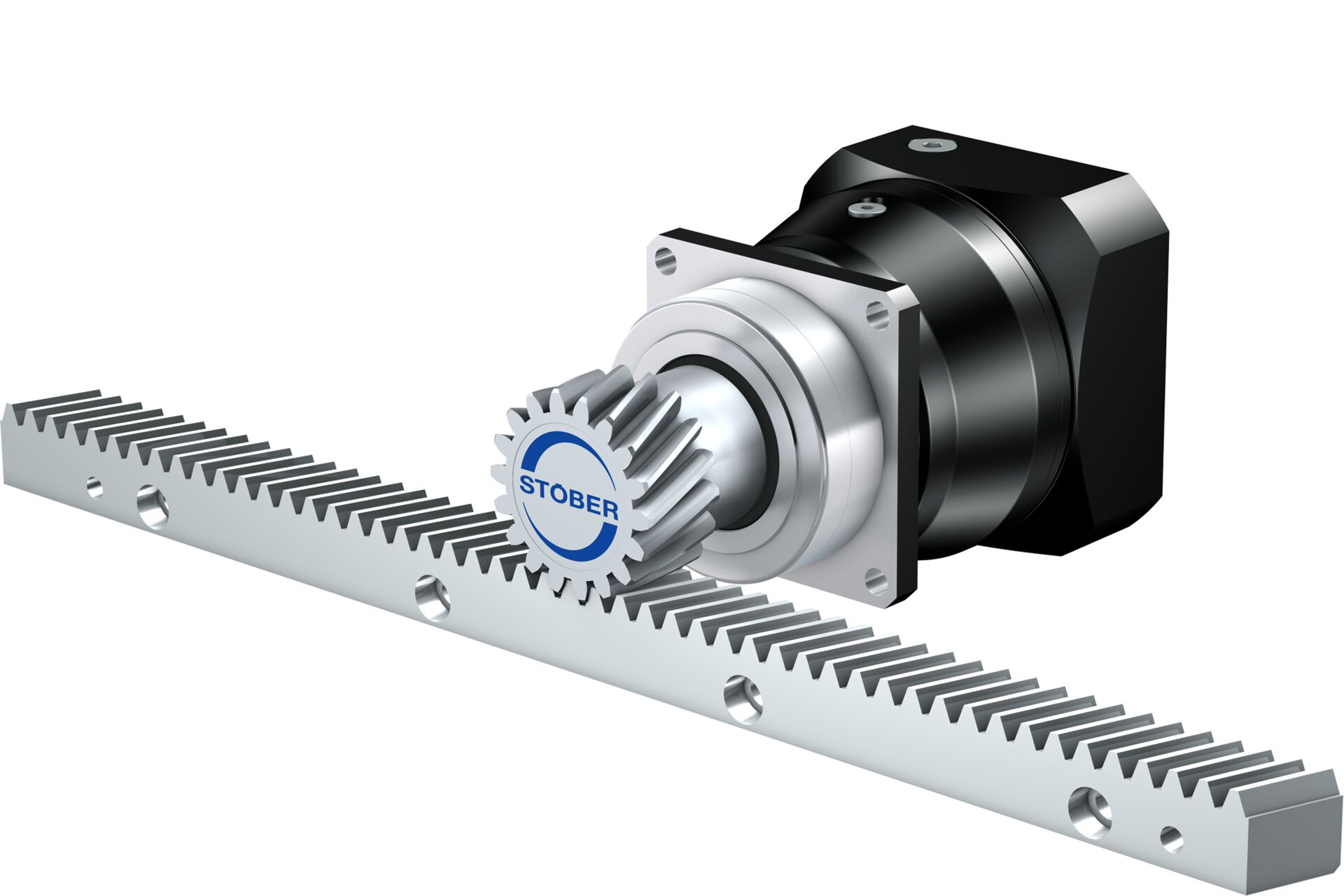

An innovative system for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs – all adapted to the different demands on load capacity and precision.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility for your pick-and-place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

An innovative system concept for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-assemble solutions including pinions, gear racks and planetary gearboxes in various designs – all adapted to the different

CONFIGURE NOW

demands for load capacity and precision.

-

ZV – High flexibility for your pick & place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

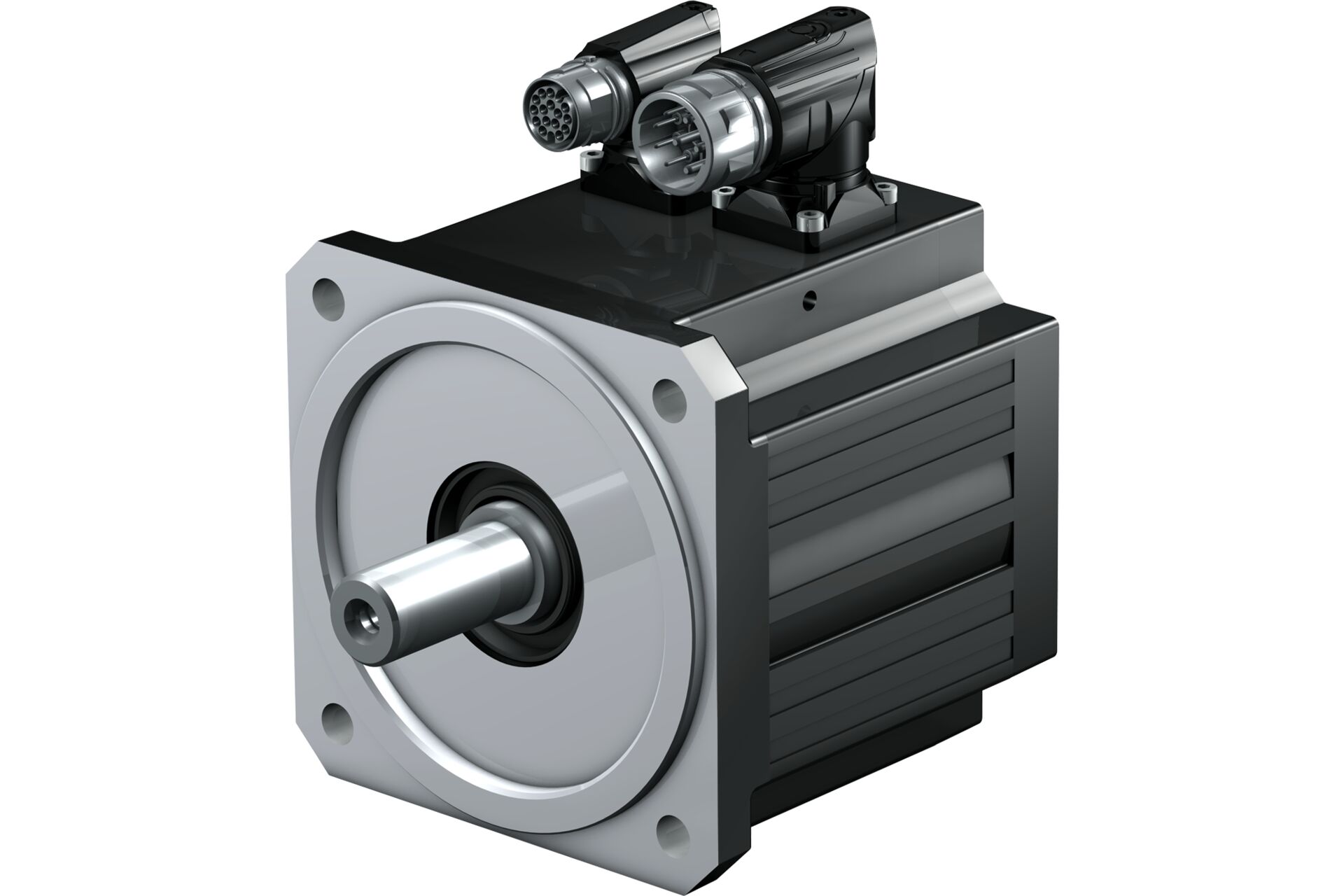

Synchronous servo motors with a high power density

For the highest positioning accuracy and dynamics, choose the extremely compact and resilient STOBER EZ series synchronous servo motors.

- Super-compact

- Maximum torque

- High dynamics

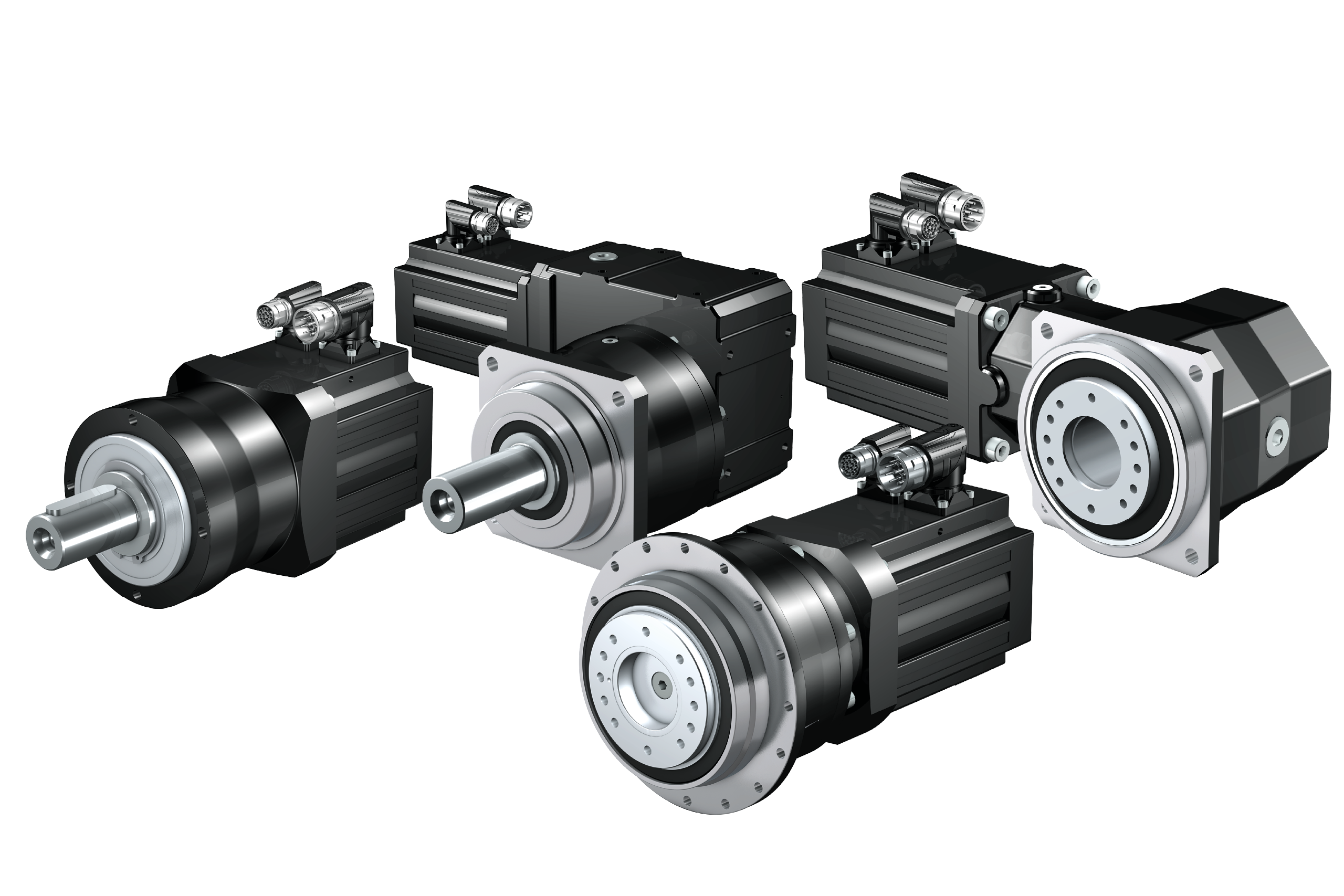

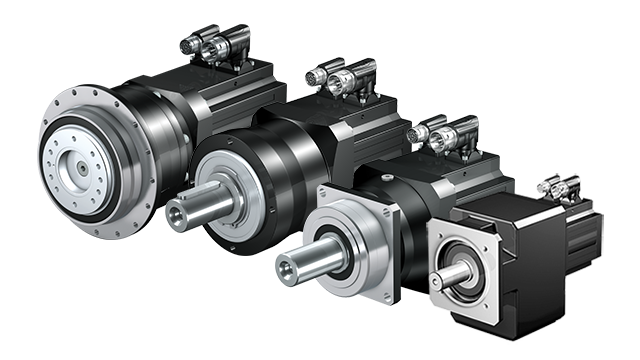

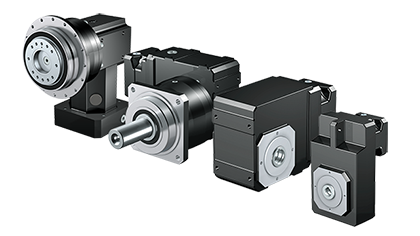

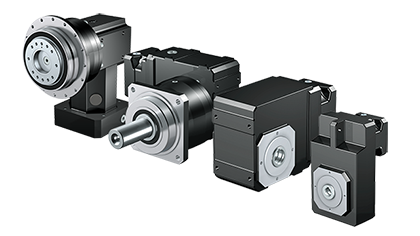

The most compact planetary geared motors on the market

The new STOBER planetary gearboxes are the most compact on the market in terms of versatility. The excellent housing and gearing quality ensures high acceleration torques as well as the highest running accuracy and precision at the same time.

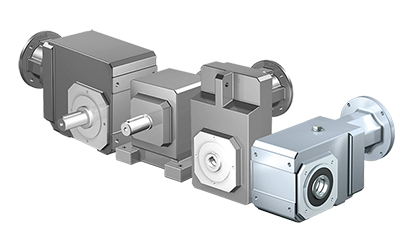

CONFIGURE NOWGear units for every mounting position

Our servo right angle gearboxes are unrivaled in their options. High-performance, extremely precise, reliable and outstanding in their particularly wide range of adaptations.

CONFIGURE NOW

CONFIGURE NOW

STOBER’s NEMA gearboxes require no maintenance. IP69K Certified, USDA Accepted Equipment, and 3 year warranty all mean our products can withstand the harshest washdowns.

Learn more

Learn more

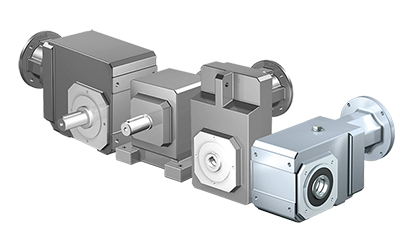

Gear units for every mounting position

Our servo right angle gearboxes are unrivaled in their options. High-performance, extremely precise, reliable and outstanding in their particularly wide range of adaptations.

CONFIGURE NOW

CONFIGURE NOW

STOBER’s NEMA gearboxes require no maintenance. IP69K Certified, USDA Accepted Equipment, and 3 year warranty all mean our products can withstand the harshest washdowns.

Learn more

Learn more