AUTOMOTIVE MANUFACTURING INDUSTRY

“69% of machine designers state that shorter product development schedules is the top machine design challenge.” – The Aberdeen Group

STOBER’s rack and pinion systems for the automotive industry are engineered quickly for a custom fit and fast delivery.

Applications and Solutions in the Automotive Manufacturing Industry

Are you driven by shorter product development cycles and faster cycle times? Need quick delivery and response? STOBER has 24/7 customer service and can build and ship your gearbox in one day.

STOBER offers several options for automotive manufacturing. Our hollow bore motors can fit in tight configurations. Safety solutions are also available, such as a dynamic safety brake or an adapter to power off operation.

Our application engineers are happy to get you a drawing and answer any questions you have. Don’t waste time waiting for your gearbox to arrive in weeks from another supplier. Get started configuring your STOBER solution now at configurator.stober.com.

COMMON CHALLENGES AND PROBLEMS

1. High need for safety

2. Tight envelopes

3. Long lead times on components

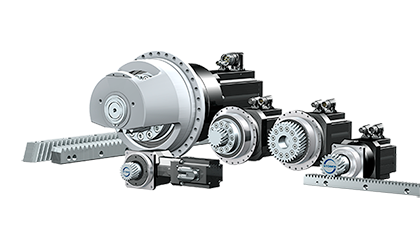

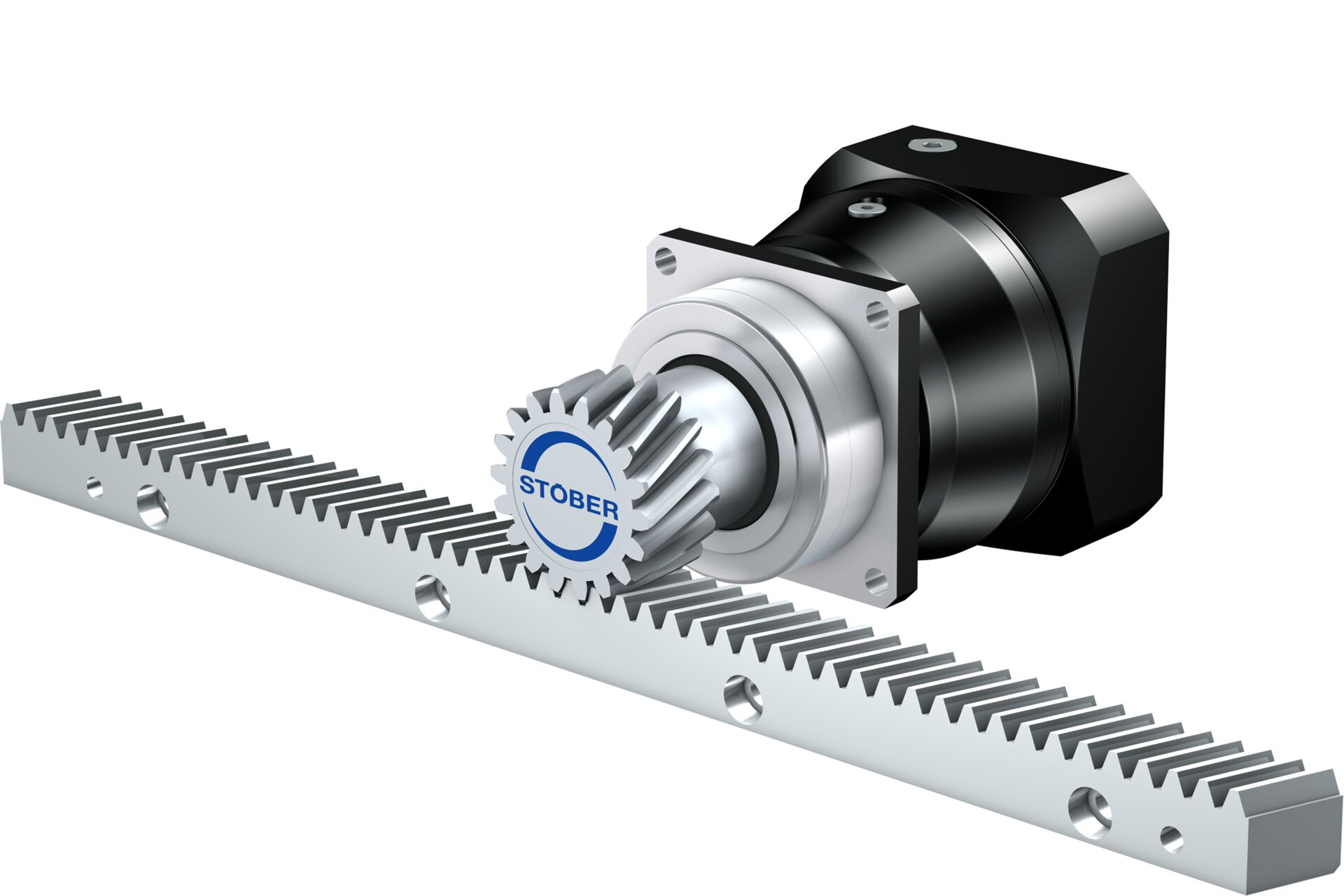

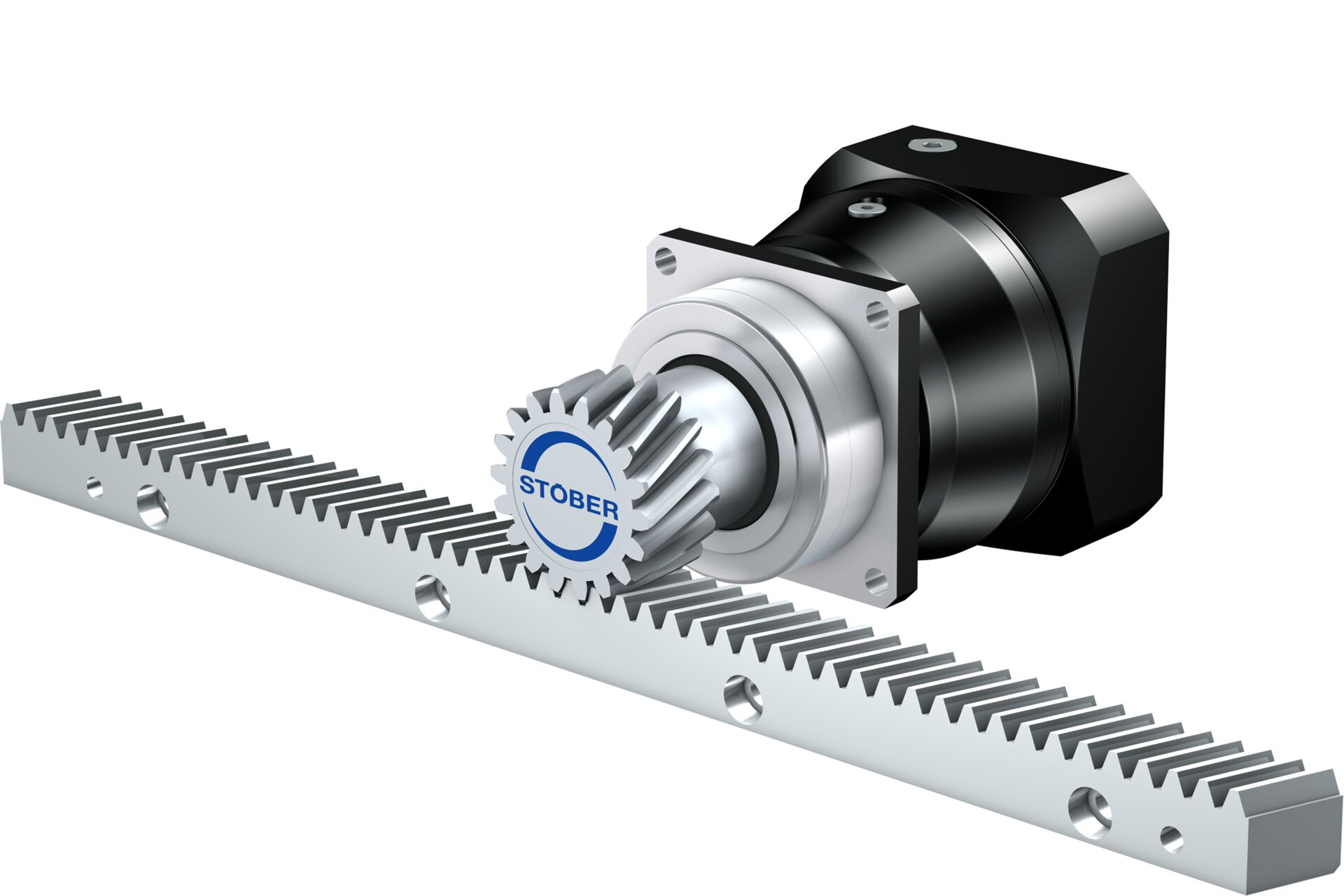

An innovative system for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs – all adapted to the different demands on load capacity and precision.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility for your pick-and-place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

An innovative system for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs – all adapted to the different demands on load capacity and precision.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility for your pick-and-place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

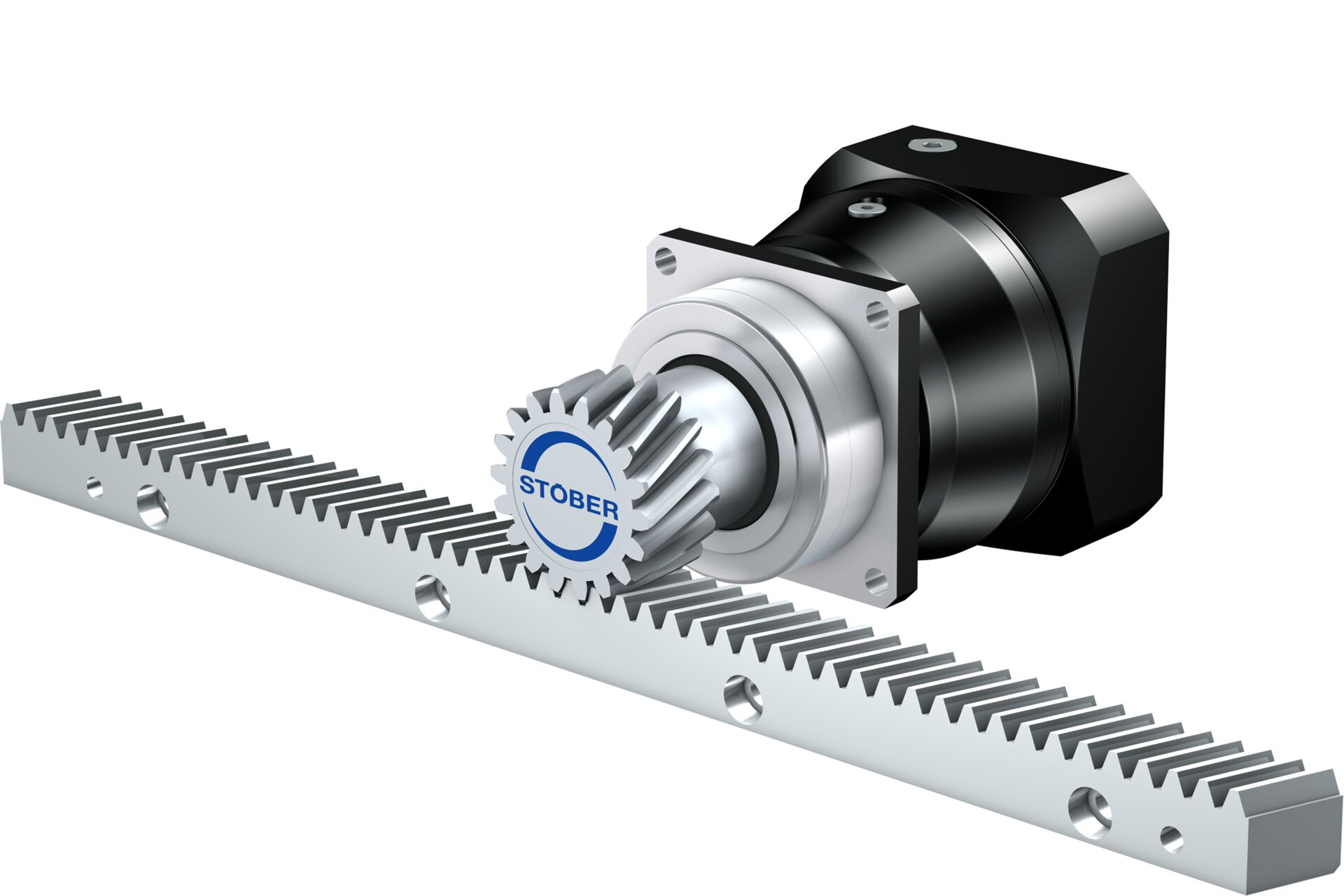

An innovative system for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs – all adapted to the different demands on load capacity and precision.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility for your pick-and-place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

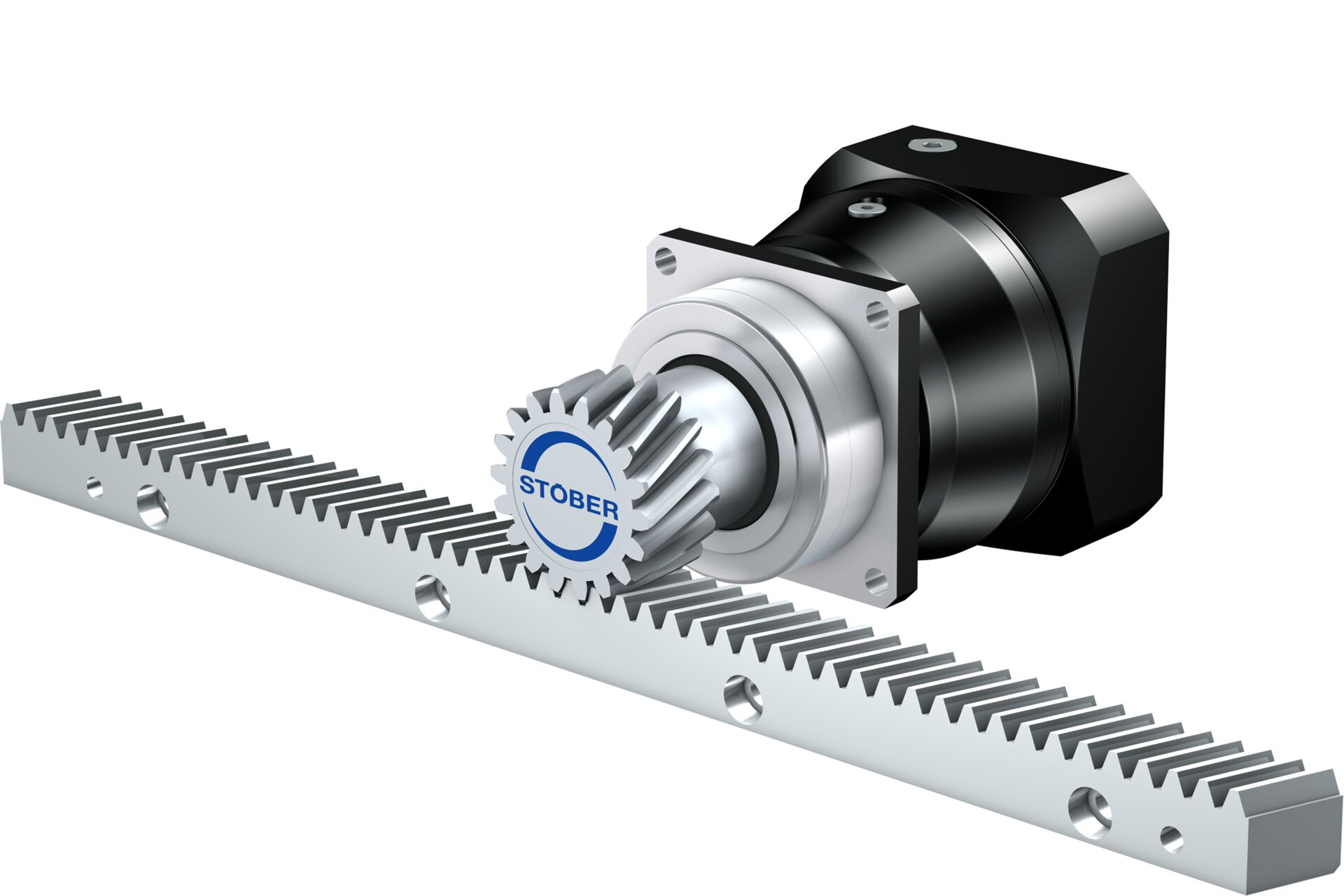

An innovative system for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs – all adapted to the different demands on load capacity and precision.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility for your pick-and-place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

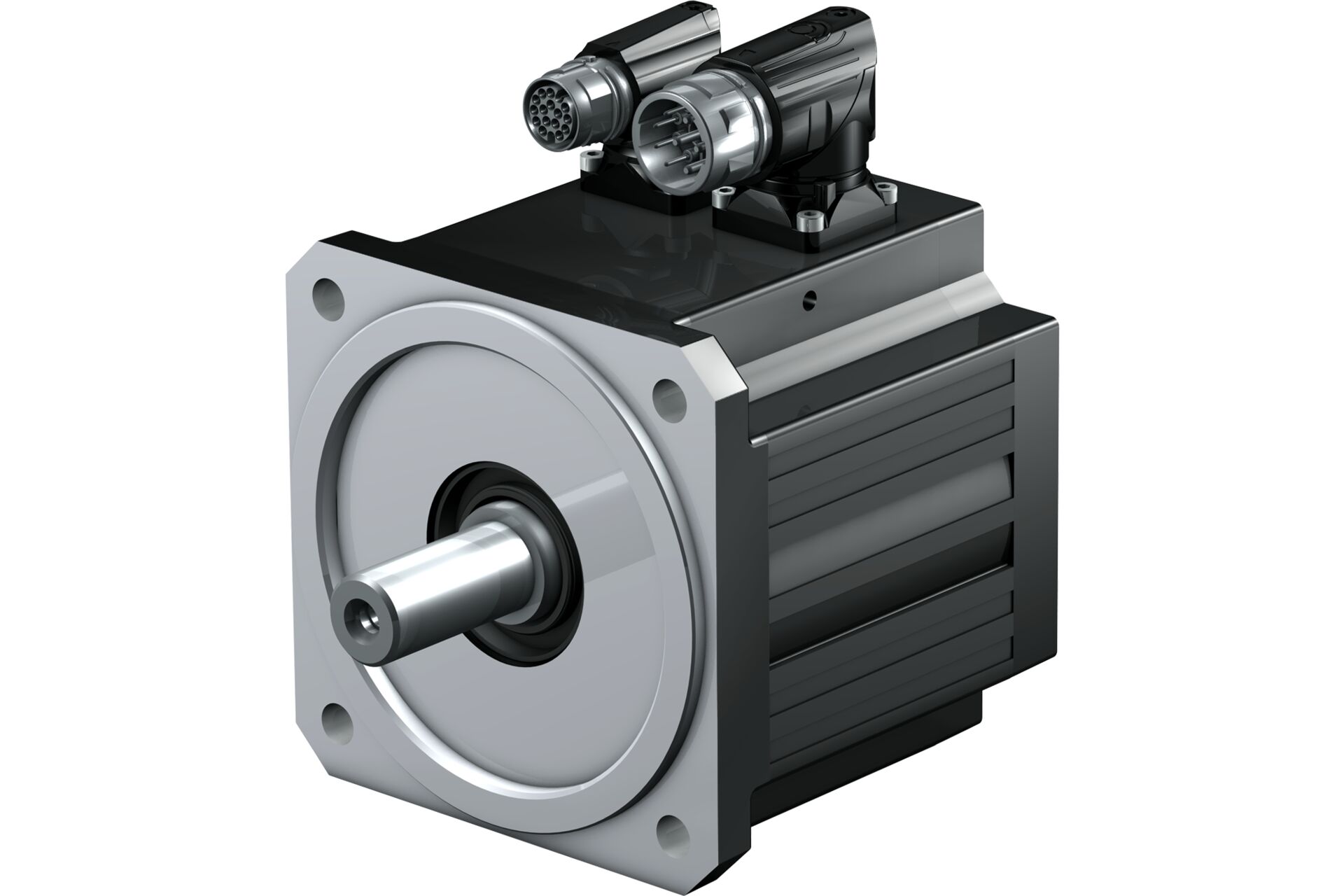

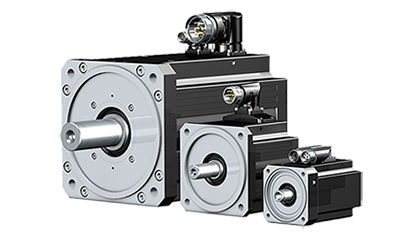

Synchronous servo motors with a high power density

For highest positioning accuracy and dynamics, choose the extremely compact and resilient STOBER synchronous servo motors of the EZ series.

- Super-compact

- Maximum torque

- High dynamics

An innovative system concept for rack and pinion gearboxes

With its rack and pinion systems, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

ZTR – High performance

- For sophisticated drive concepts

- Small pinion diameters

- High linear stiffness

An innovative system concept for rack and pinion gearboxes

With its rack and pinion systems, STOBER offers ready-to-install solutions consisting of pinions, gear racks and planetary gearboxes in various designs.

CONFIGURE NOW

CONFIGURE NOW

ZV – High flexibility

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

ZTR – High performance

- For sophisticated drive concepts

- Small pinion diameters

- High linear stiffness

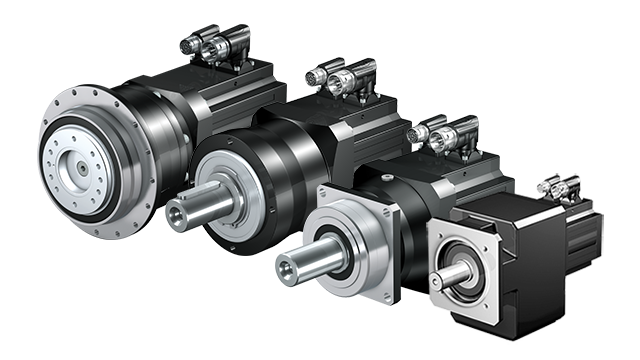

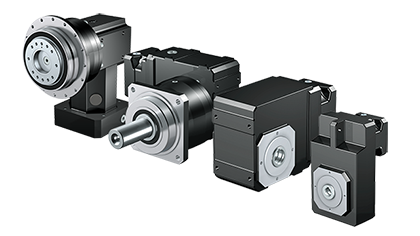

The most compact planetary geared motors on the market

The new STOBER planetary gearboxes are the most compact on the market in terms of versatility. Due to the lower mass moment of inertia by leaving out a motor adapter, you can also utilize the full dynamics of the drive.

CONFIGURE NOW

CONFIGURE NOW

The excellent housing and gearing quality ensures high acceleration torques and also the highest running accuracy and precision.

You will be convinced of the extraordinary variety of combinations and options from which you can find the right solution for your application.

Learn moreThe most compact planetary geared motors on the market

The new STOBER planetary gearboxes are the most compact on the market in terms of versatility. Due to the lower mass moment of inertia by leaving out a motor adapter, you can also utilize the full dynamics of the drive.

CONFIGURE NOW

CONFIGURE NOW

The excellent housing and gearing quality ensures high acceleration torques and also the highest running accuracy and precision.

You will be convinced of the extraordinary variety of combinations and options from which you can find the right solution for your application.

Learn more