STOBER knows gearbox oil may seem like a small detail, but it makes a huge difference in the life of a gearbox. That’s why we evaluate our lubrication thoroughly—our Exxon Mobil lubrication has undergone substantial testing and analysis to ensure your application requirements are met. Our oil plugs use neodymium magnets, which remove any contaminants.

Here are the top five things to think about when considering gearbox oil selection criteria:

- What type of oil do I need for my application?

Choosing the best oil for industrial gearboxes means understanding the equipment’s role and operating environment. Synthetic oils generally have a wider operating temperature and oxidation rate, but mineral oils are suitable for most applications. Synthetic oil can be formulated for specific applications such as food and beverage. Synthetic lubrication can have an increased life expectancy over mineral oil. Make sure to also consider the oil’s viscosity, operating temperature, oxidation rates, and application requirements during selection.

- What tests are done on the oil?

As the gearbox operates and the oil expands, pressure builds inside the unit. The user must ventilate the gearbox if the unit is unable to compensate for thermal expansion.

Most oil companies will perform a Flender Test to determine if antifoaming additives are needed. Compatibility with bearings and seals should be tested as oil can harden the seal material and cause leaks between the seal and gearbox shaft.

- What is the oil’s composition?

An oil’s composition should always account for application considerations. Certain applications may need extreme pressure additives, oxidation stabilizers, corrosion protection, or friction and wear reducing characteristics to avoid premature failure.

- Who controls the oil composition?

Oil manufacturers should be responsible for the composition of oil by inserting additives to a base oil. Be sure to ask if the gearbox manufacturer makes any changes to the oil and if it is rated for the intended application specs.

- How is the oil filtered?

Some contaminants have the potential to remain after parts are machined and washed. Metal shavings can float in the oil and reach the seals, which can cause seal damage and cause potential leaks. Some companies use magnetic oil plugs to extract these contaminants from the oil.

The Cost of Choosing the Wrong Oil

All lubricants ultimately serve the same basic purpose, but choosing the wrong oil for a gearbox can have disastrous consequences in the long term. Without oil specifically formulated for the exact situation, gearboxes can experience accelerated wear and excessive heat generation. These conditions can lead to equipment breaking down more frequently, consuming too much energy or requiring excessive maintenance to keep it in working order. Certain oils may not be compatible with the materials used in gaskets and oil seals, which means they may deteriorate prematurely.

Such oil-related equipment failures don’t happen immediately, either. The damages caused by incompatible oils can take a long time to manifest themselves in a visible way. By the time the problem is identified, it may be too late to do anything about it. Our rigorous gearbox oil compatibility testing and checks help manufacturers eliminate guesswork and prevent these costly failures.

Industry-Specific Gearbox Oil Needs

The right oil for a gearbox depends a lot on the specific requirements of the industry in which it will be used. For example:

- Food and beverage manufacturers need food-grade gearbox oils that resist washdowns and prevent contamination on the production line

- Packaging and automation operations are focused on precision, low noise levels and oils that support consistent high-speed operation

- Heavy industry players in mining, material handling and other sectors need oils with high load capacities, extreme pressure resistance and long oxidation life

- Cleanroom and medical environments require oils formulated for low off-gassing, cleanliness and compliance with their strict regulatory standards

STOBER’s Exxon Mobil formulations have been tested across these and other industries to ensure compliance and reliability in diverse applications.

Oil Longevity and Change Intervals

In most gearboxes, regular oil changes are necessary to prevent oxidation, additive depletion or contamination buildup. Gear oil life expectancy can differ based on the operating temperature, load conditions and presence of any contaminants. However, frequent gearbox oil service intervals can increase labor costs, downtime and disposal needs. This is what makes STOBER’s innovative “no oil change required” designs so valuable for manufacturers. With advanced sealing, magnetic plugs for filtration and validated oil testing, we help cut down on the total cost of ownership while also saving operators time over the lifecycle of the gearbox.

Oil is one of the most vital parts of a gearbox, yet many manufacturers treat it as an afterthought. Leaking gearboxes are a maintenance nightmare – especially in food or beverage applications.

When you use STOBER products, you can rest assured that your industrial gearbox oil is fully evaluated to match your application and product needs. Plus, no oil changes are required on STOBER products, saving you time and money.

Check out our free download to see why oil differences matter.

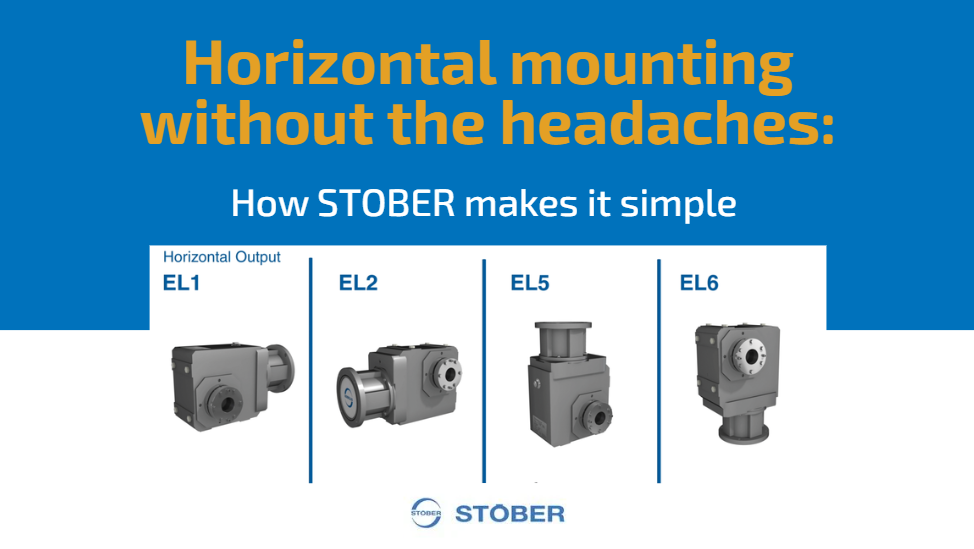

Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices  How to find information about an old STOBER unit or item in inventory

How to find information about an old STOBER unit or item in inventory