Designing high-performance machines while competing with low-cost alternatives can be a complicated process. Engineering resources can be spread thin, which can extend design time, and minimizing machine envelope while maintaining performance can be a real challenge. But STOBER’s experience and product knowledge can solve all of these problems and more!

Whether for carbon fiber tape laying, mills, plasma cutting, grinding, bending & forming, or other forms of deformations, STOBER offers solutions for many applications that have major benefits. These options include:

- Planetary Solutions

- 5-year warranty

- Accurate positioning at very high speeds

- No maintenance

- Lowest backlash rating available

- Geared Motor/Motor Solutions

- 2-year warranty

- Compact: save more space with no motor adapter

- One supplier for easier sizing and communication

- Extreme torque density

- Better dynamic performance

- Rack and Pinion Solutions

- 2-year warranty

- Options for high force or high speed

- Sizing calculations done by STOBER experts

- Support selecting best ration and pinion tooth count to maximize throughput

STOBER solutions also feature plug ‘n play connectivity with B&R, Beckhoff, Bosch, Kollmorgen, Rockwell, and Siemens drives. To take it a step further, STOBER offers many additional advantages such as longer life, fast delivery, 24/7-365 support, global application support, and minimal lost motion.

Want to learn more? Click the link below to download the STOBER Machine Tool Insight brochure!

Selecting gearboxes for robotic & industrial automation systems

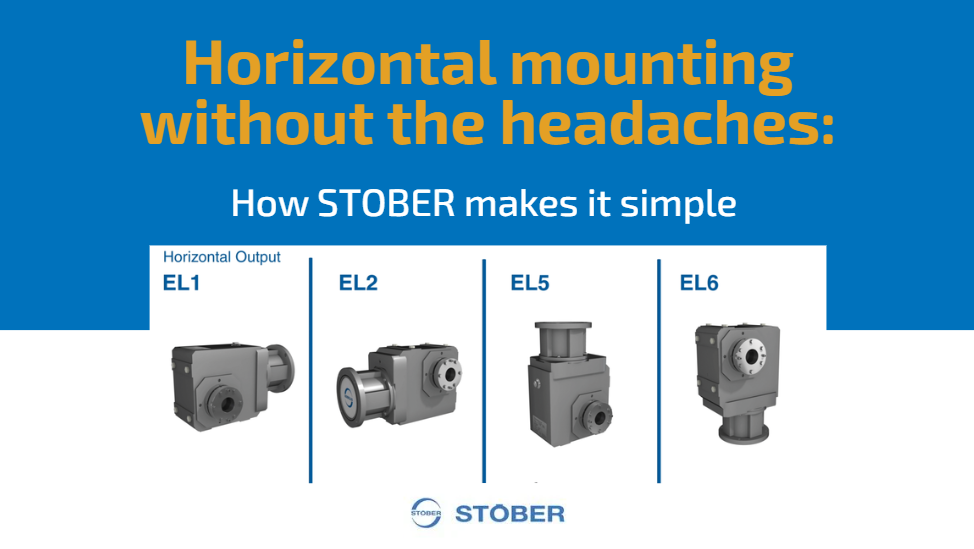

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices