When sizing for applications that require precision, many engineers only consider backlash. However, backlash is only one piece of the puzzle. There are many other elements to keep in mind.

Total lost motion is crucial when sizing applications requiring dynamic and precise movement. Lost motion encompasses backlash, play between components, strength of the transmission, and material deformities.

Here are 2 key areas to examine when sizing for precise applications:

1. Backlash – The more backlash a gearbox has, the less precise it will be in the application.

2. Torsional stiffness – The higher the torsional stiffness, the easier it is to have a repeatable movement.

With STOBER’s Generation 3 Planetary series, you can eliminate backlash and lost motion. This new gearbox series features wider gear teeth, so there’s more surface area contact. It offers smoothness of motion and up to a 50% increase in stiffness. There is also an option for reduced backlash, allowing you to take advantage of the most precise unit on the market. Every unit is tested for friction, noise, ratio, and runout on our state-of-the-art end of line tester.

Want to learn more? Check out our Power Tips episode!

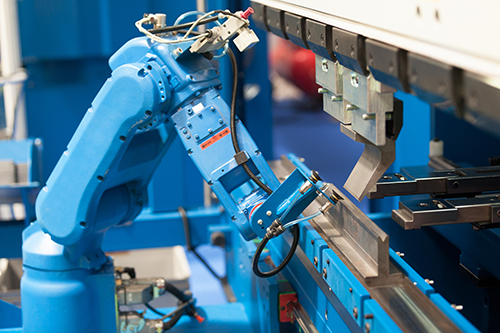

Selecting gearboxes for robotic & industrial automation systems

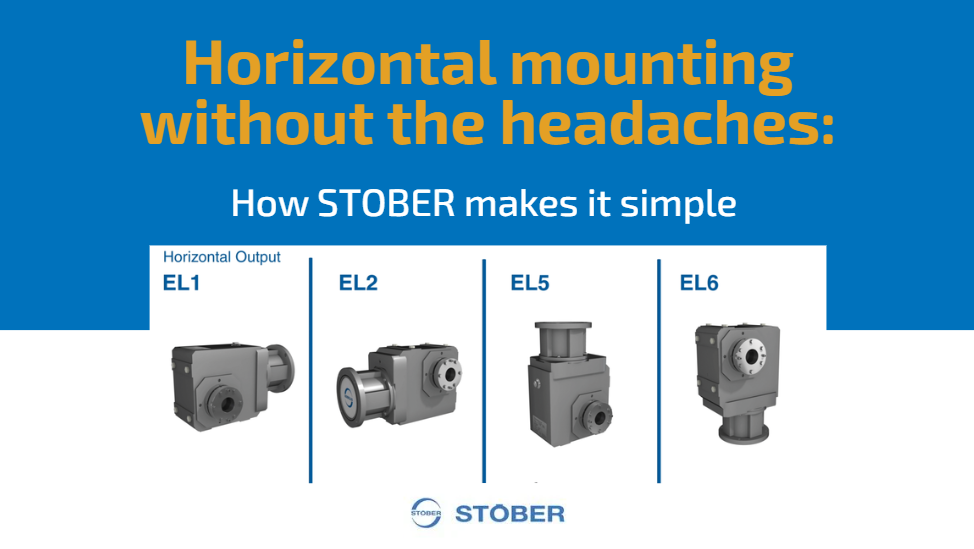

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs  Gearbox noise reduction: Causes, fixes & best practices

Gearbox noise reduction: Causes, fixes & best practices