FOOD INDUSTRY

“The annual downtime for food and beverage production is more than 10 weeks per year.” – Harting

Eliminate Unplanned Downtime

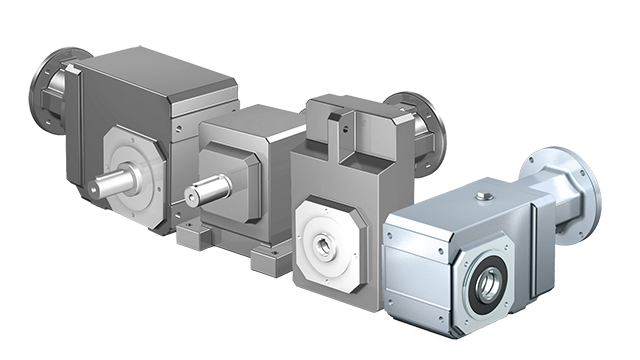

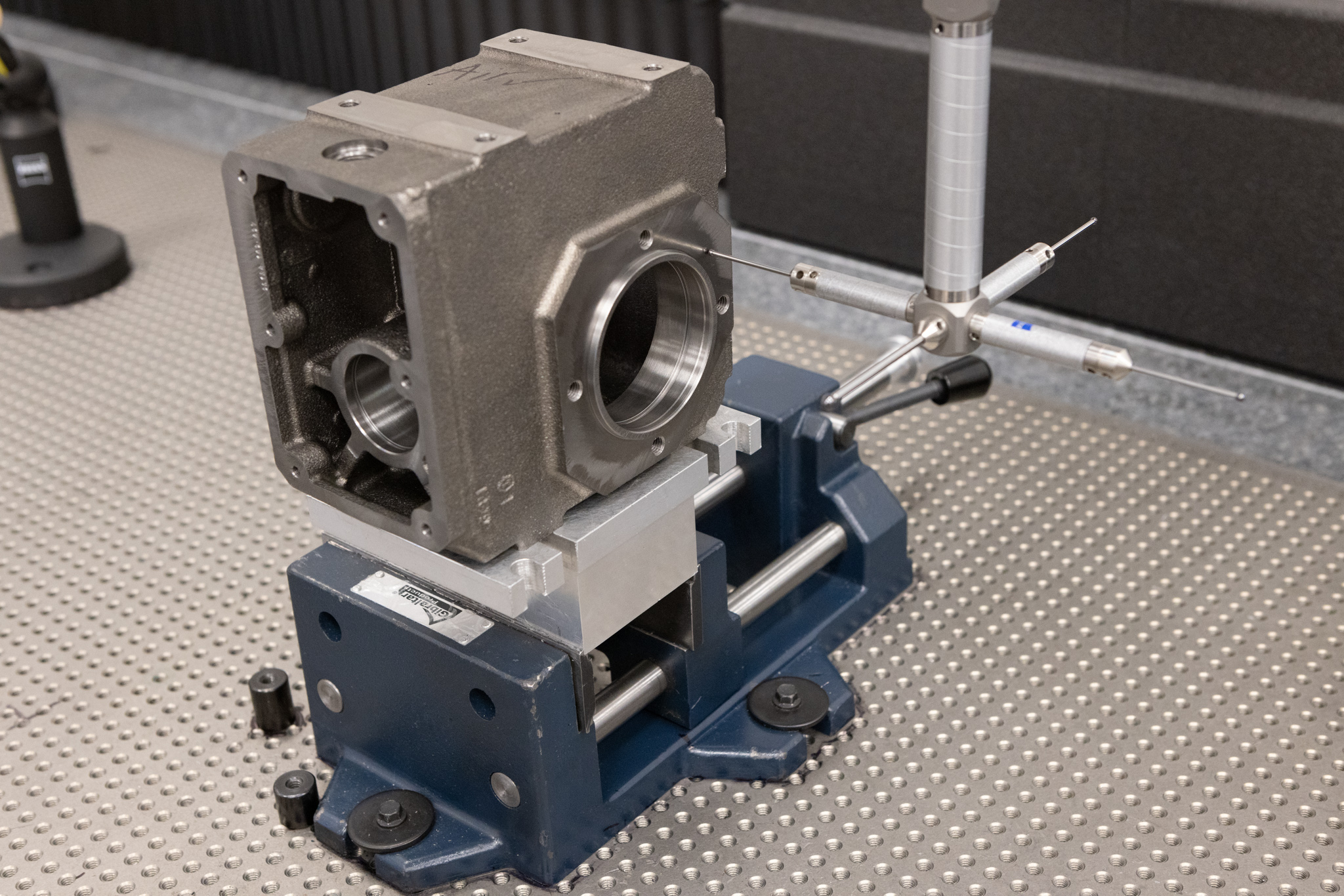

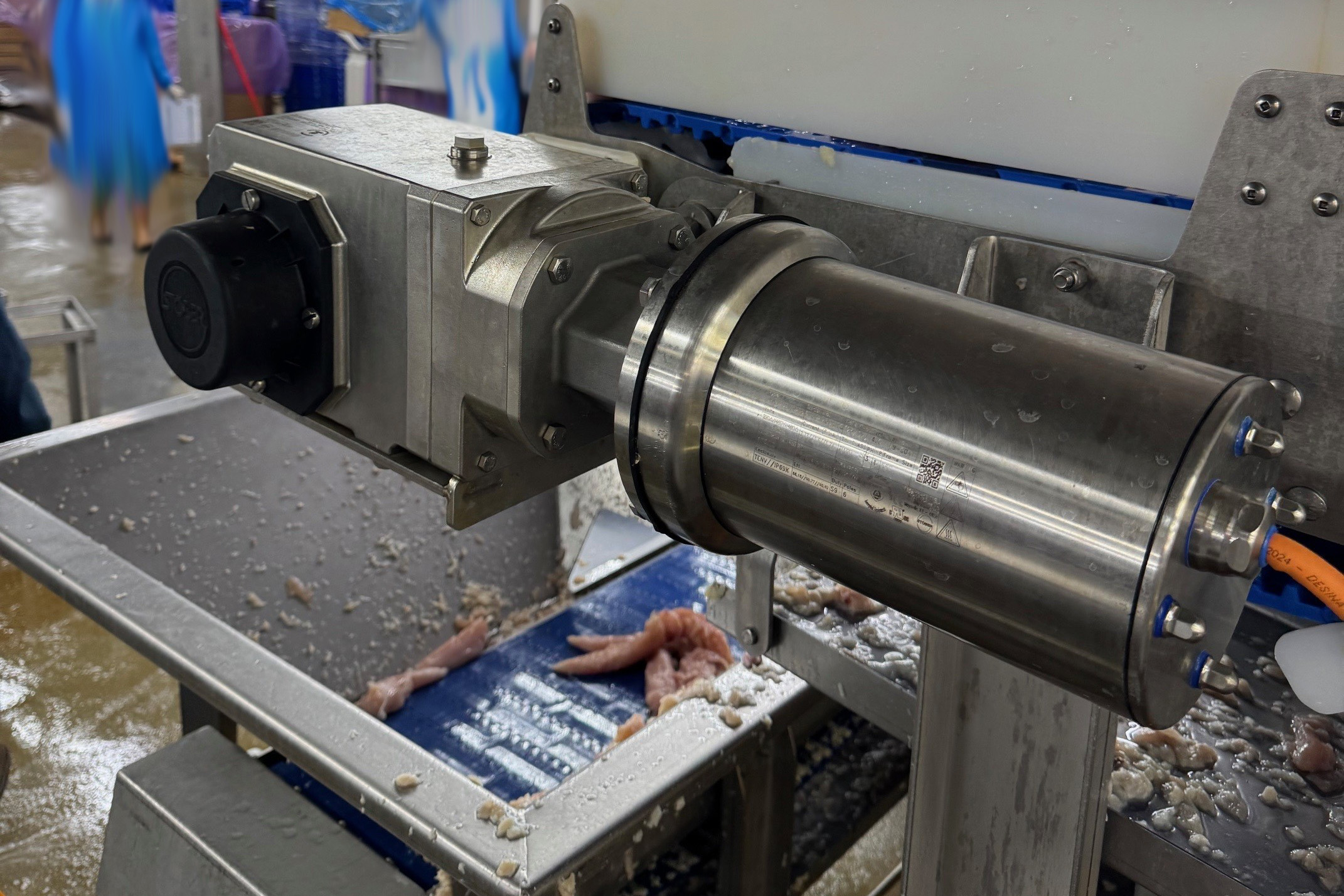

When it comes to the harsh environment of food production and food industry gearboxes, look no further than STOBER solutions that pass the test of rigid washdowns, abrasive chemicals, and continuous operation, preventing premature failure and saving thousands of dollars in downtime. The top gearbox of choice for 16 of the top 20 food manufacturers in the U.S., STOBER’s stainless steel, food-duty gearboxes and new cLEAN System can handle the most stringent cleaning regiments, including harsh washdowns.

STOBER provides unsurpassed solutions for processed and ready-to-eat foods and offers products able to withstand the toughest cleaning regiments, including IP69K. Our industry-leading warranty gives you the peace of mind that the next routine washdown won’t cause major downtime.

Experts in the food industry since 1997, STOBER’s dedicated team provides support for the life of the product–from sizing to installation and beyond. The average mean time to failure for STOBER gearboxes in 24/7 harsh washdown environments is 9.1 years. STOBER products are backed by a 3-year warranty, ship in one day, and allow you to say goodbye to headaches caused by premature failures, contamination risks, and costly downtime.

What Sets Us Apart:

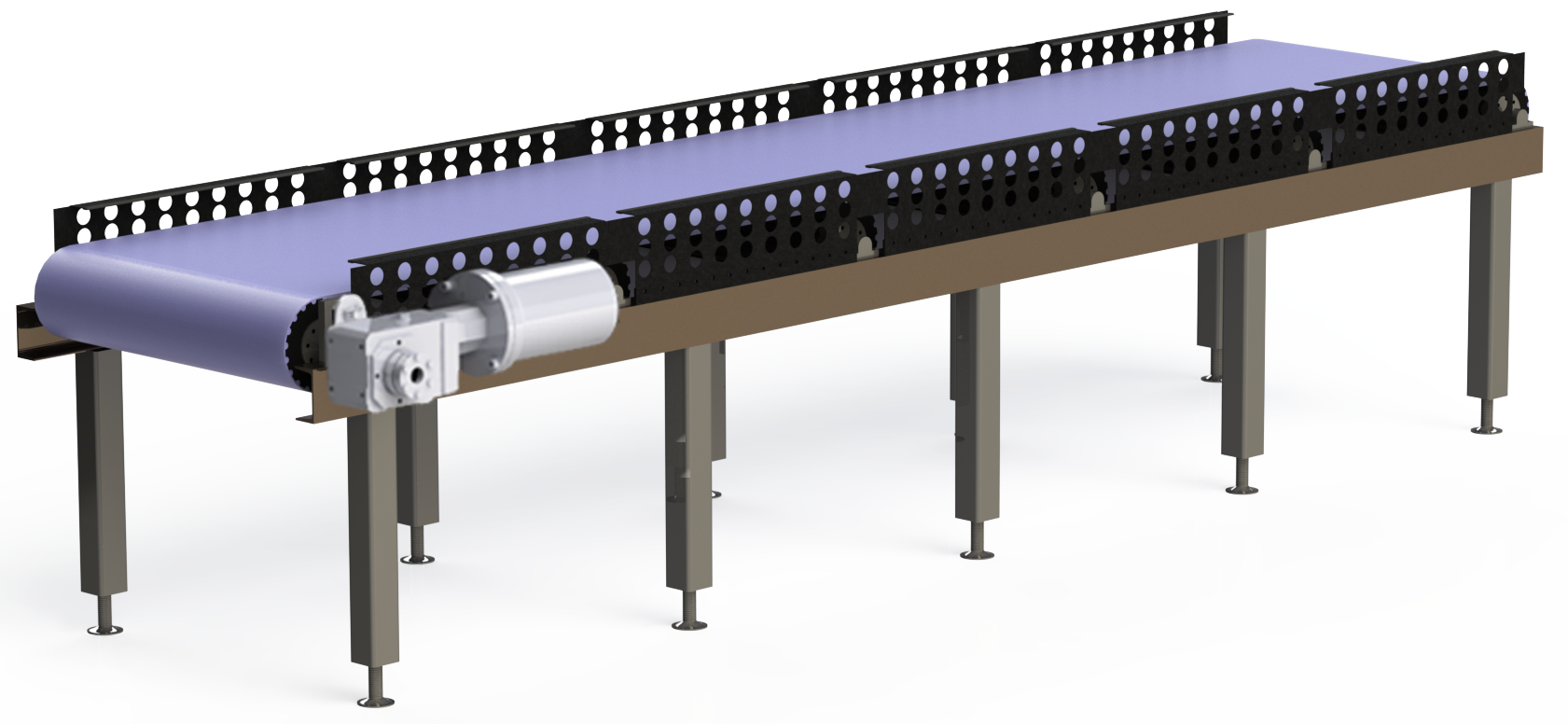

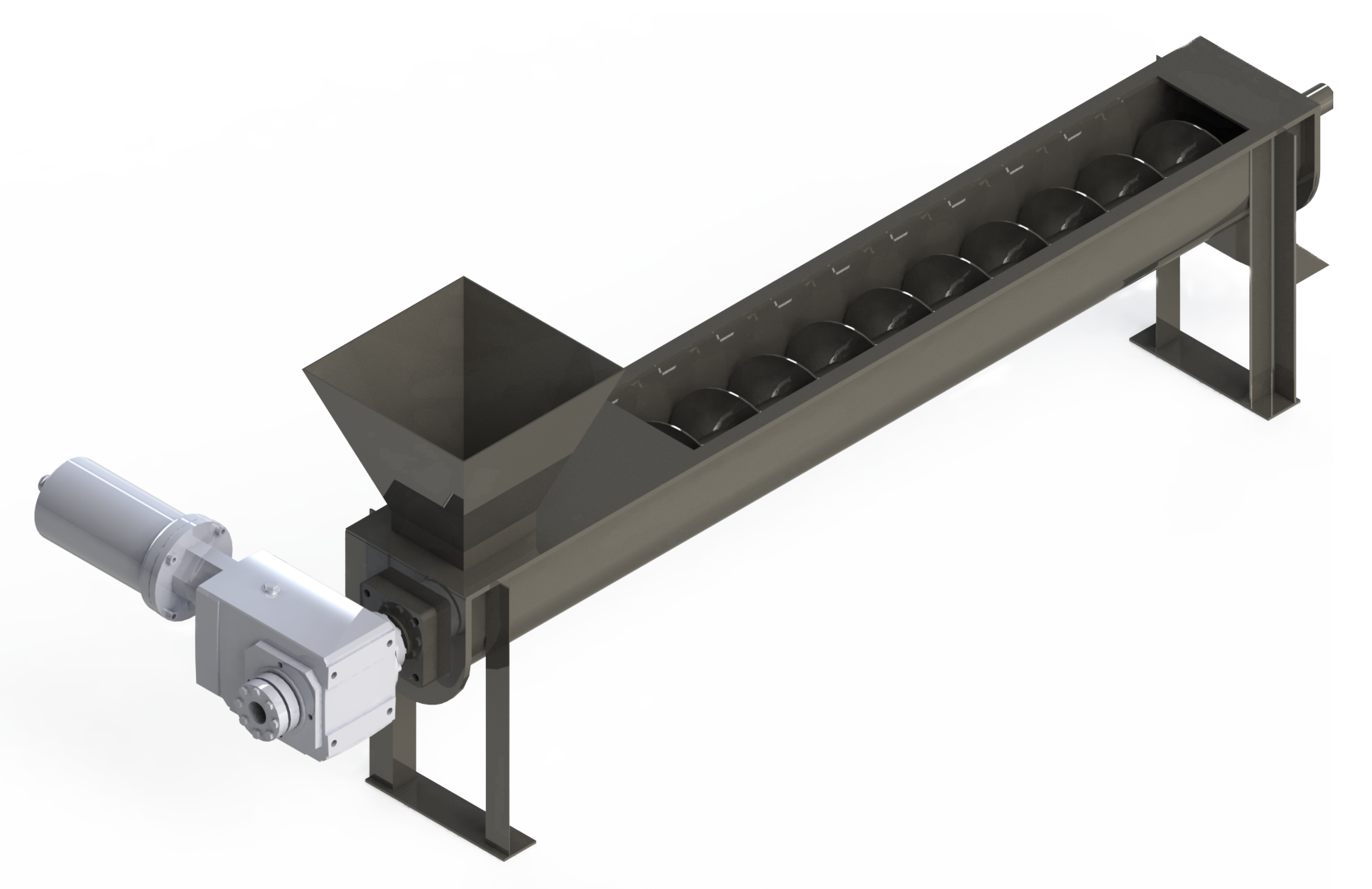

STOBER Applications in the Food Industry

STOBER’s Stainless Steel cLEAN System

cLEAN System has zero weep holes, meaning water cannot get into the motor. This eliminates premature failure due to water ingress.

STOBER doesn’t just talk about being the World’s Toughest System – the claim is backed by the industry-leading warranty customers expect from STOBER. Gearbox, motor, drive, and cable are all covered with a three-year warranty.

Most NEMA motors are 85.3% efficiency. The cLEAN Motor is over 93% efficient, savings thousands of dollars in energy expenditures.

FOOD INDUSTRY PRODUCTS

Reliability You Can Count On

STOBER is the world’s leading expert in solutions for the food processing industry. Food production is a harsh environment. STOBER’s solutions pass the test of rigid washdowns and continuous operation, preventing premature failure and saving thousands of dollars in downtime. STOBER provides fast delivery, unparalleled support, and years of cost-savings.

Customer Testimonials

NEWS FROM STOBER

Gearbox noise reduction: Causes, fixes & best practices

Reduce gearbox noise by fixing root causes like gear mesh issues, poor lubrication, misalignment, and vibration so drives run smoother, quieter, and longer….

How to find information about an old STOBER unit or

Looking for details on an old STOBER unit or inventory item? Use the STOBER Product ID Tool to instantly access installation guides, technical specs, and…

Year in review: Top blog posts of 2025

Discover STOBER’s most-read blogs of 2025—from maintenance tips to success stories. Catch up on the insights that shaped the year before 2026 begins!…