PACKAGING INDUSTRY

Engineered for Extreme Washdown, Rapid Cycle Packaging Lines & 24/7 Operation

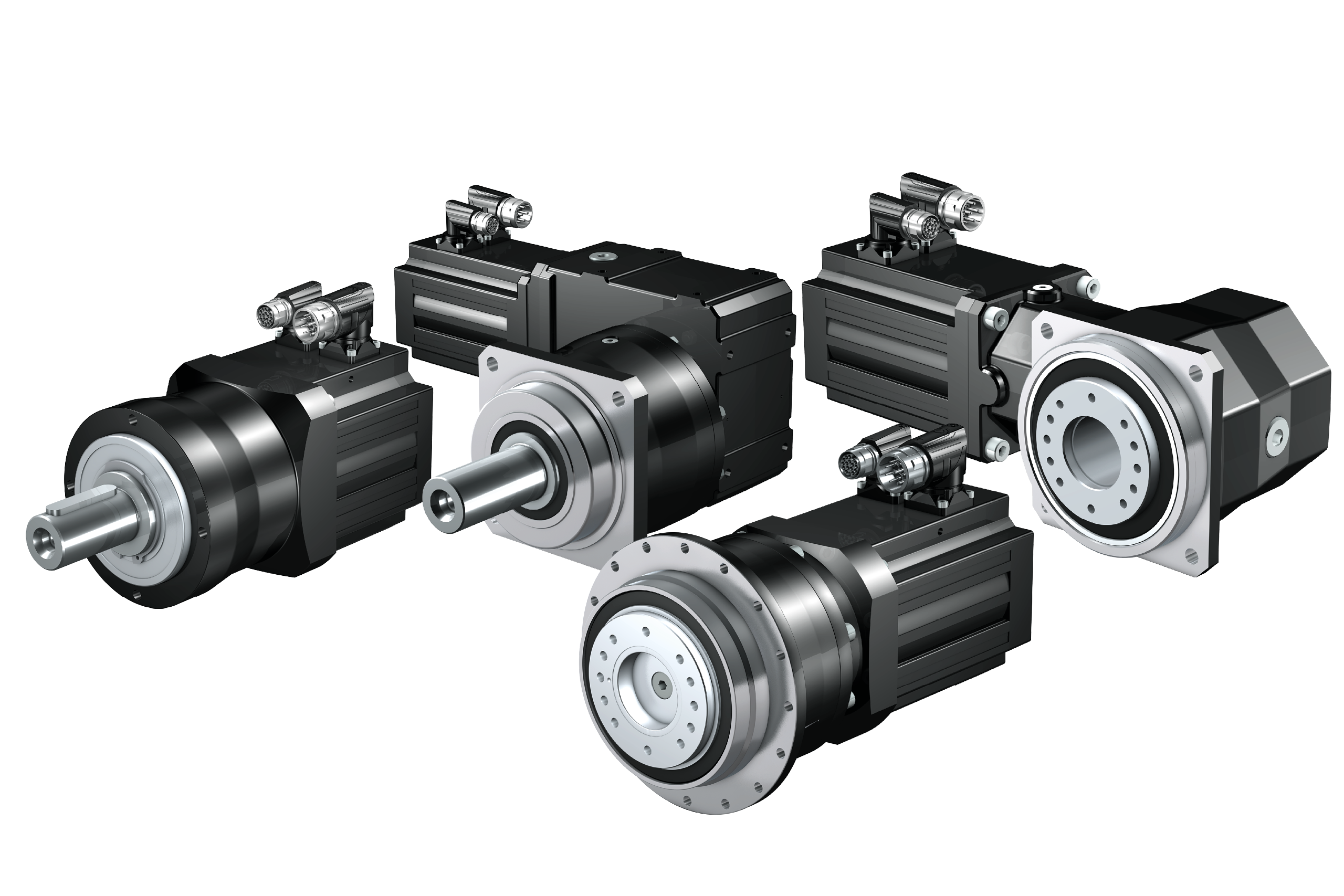

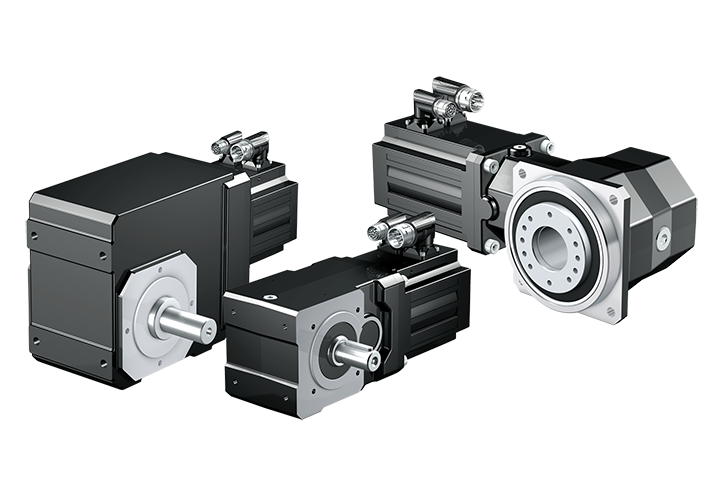

Precision gearboxes and servo geared motors for high-performance packaging systems

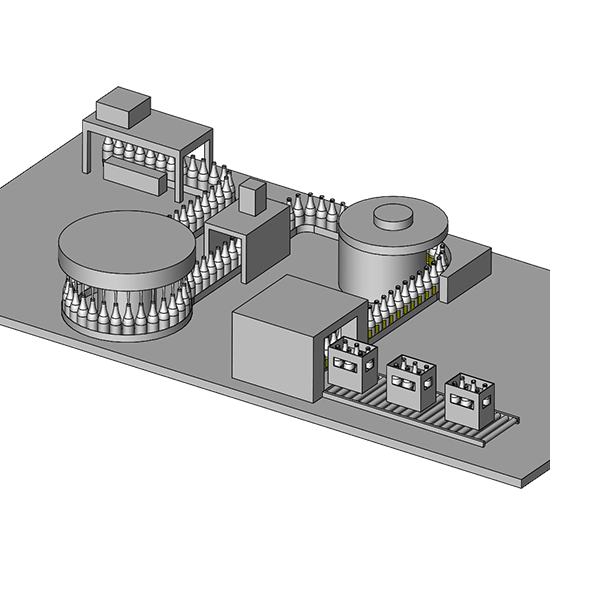

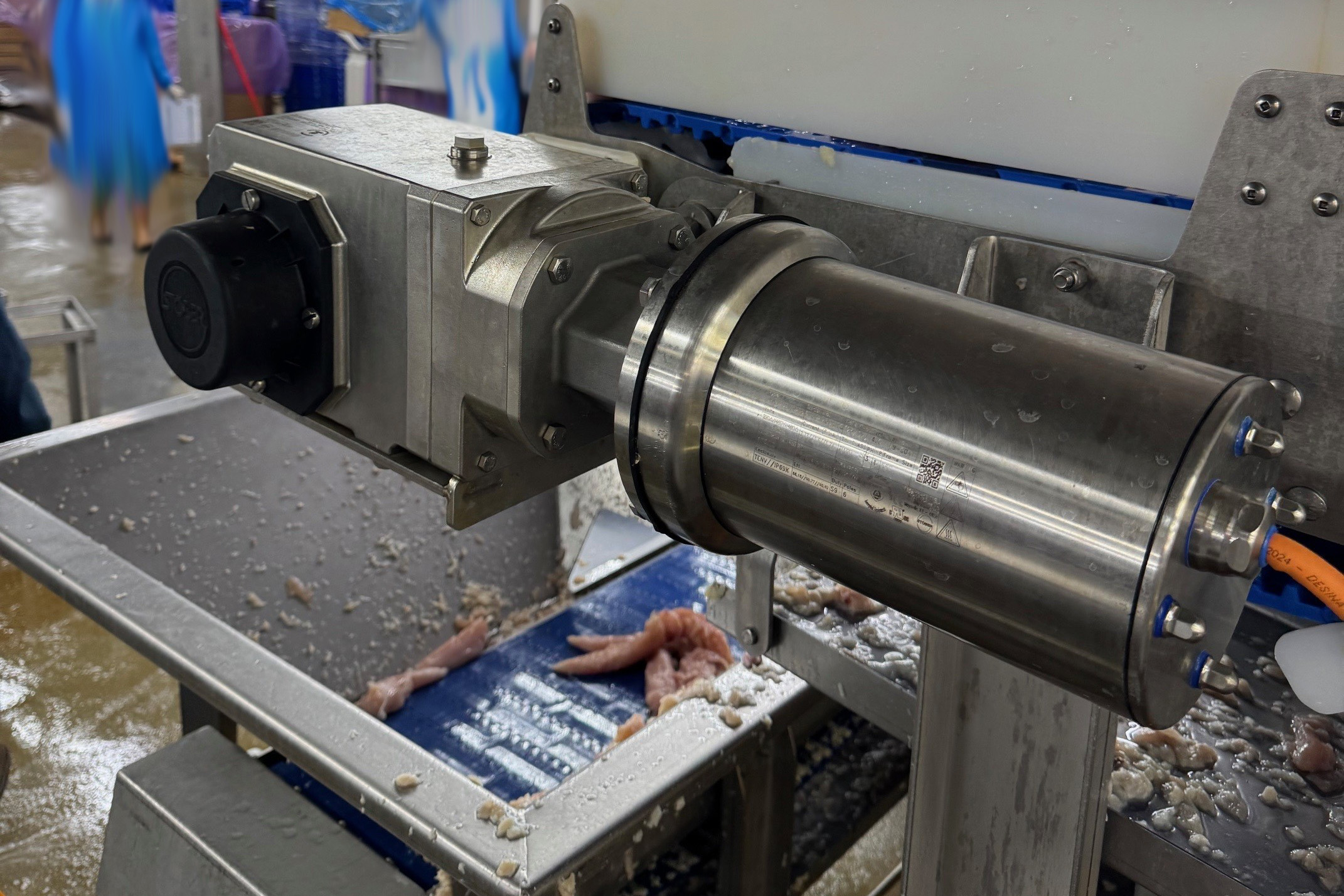

Costly floor space and production demands are relentless in the packaging industry, where every inch counts and every second matters. STOBER delivers compact, high-efficiency drive solutions engineered for precision, durability, and performance. Our gearboxes and geared motors are designed to minimize equipment footprint by up to 20 percent, while maximizing performance to meet the demands of high-speed, high-precision packaging environments. Whether your system requires inline, right-angle, or planetary configurations, STOBER offers tailored solutions that meet the mechanical and performance demands of modern packaging lines.

What Sets Us Apart:

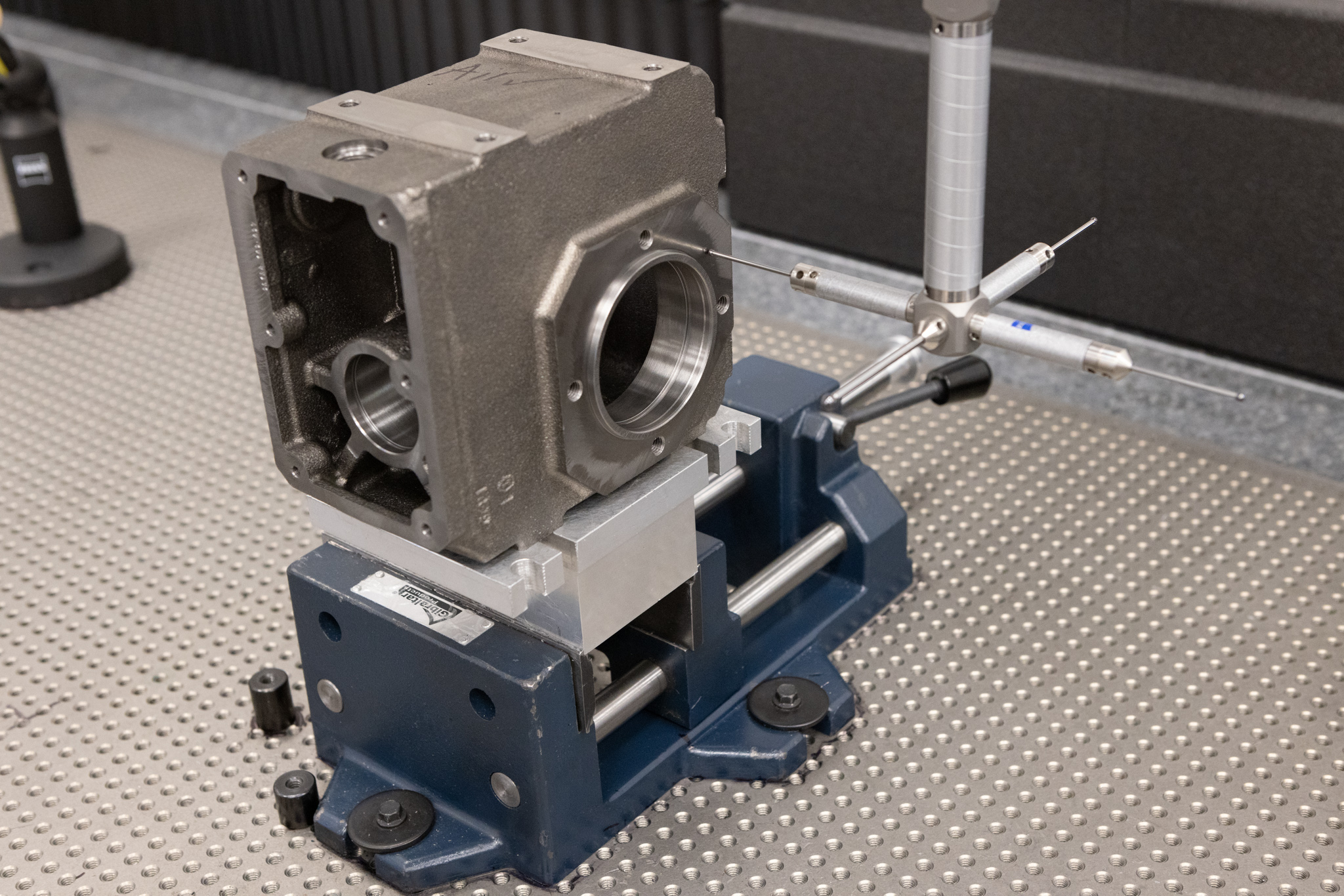

STOBER’s gearboxes are built with premium housing and gearing to ensure:

STOBER’s synchronous servo geared motors are engineered for:

Engineered for packaging applications

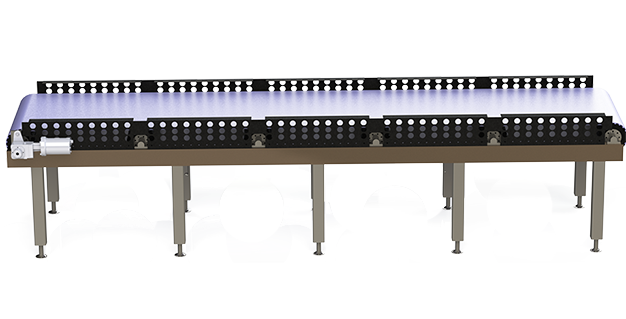

The most compact planetary geared motors on the market

The new STOBER planetary gearboxes are the most compact on the market in terms of versatility. The excellent housing and gearing quality ensures high acceleration torques as well as planetary gearmotors the highest running accuracy and precision at the same time.

Practical without any compromises – servo geared motors

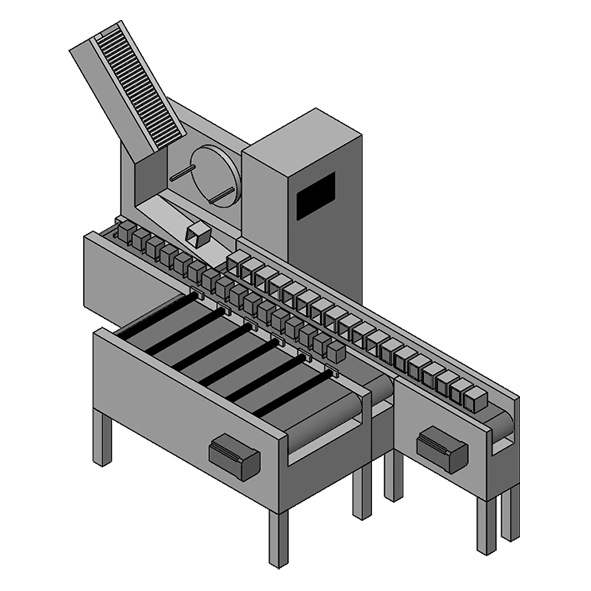

Are you looking for higher dynamics, lower weight, and very small installation space for the angular transmission of motion and forces? The solution from STOBER is the KL series of helical bevel gearboxes!

- Made from one mold

- Combined with STOBER synchronous servo motors, this means a coupling-free connection that reduces the space requirement, the rotating masses and the associated weight

- Extremely attractive price-performance ratio

Servo geared motors: Compact, resilient, and precise

STOBER’s inline and right-angle helical bevel gearboxes and EZ series synchronous servo motors are engineered for:

Compact design with reduced rotating mass

Direct connection to STOBER motors for reduced installation complexity

Ideal for high-speed, high-precision packaging tasks

Optimize your packaging line with STOBER

STOBER’s engineering team provides complete system calculations to ensure optimal performance. From NEMA gearboxes to rack and pinion systems, our solutions are designed to handle high force, high speed, and high precision—without compromise.

We’re more than just great products—we love making your life easier with modular systems, U.S. based support in Maysville, Ky., and fast shipping.

Check out the table below to see how we stack up against typical industry solutions, then contact us at 1-888-786-2371 or email sales@stober.com when you’re ready to configure a STOBER solution for your application.

STOBER packaging applications vs. typical industry solutions

| Feature / Spec | STOBER Solutions | Typical Industry Solutions |

| Backlash | Zero‑backlash gearing (<1 arcmin) for precise, repeatable positioning | 5–10 arcmin common, leading to cumulative positioning errors |

| Gearbox Length | Ultra‑short installation length for compact machine layouts | Longer housings that increase machine footprint |

| Power Density | High torque output in minimal space | Lower torque‑to‑size ratio |

| Integration | Motor + gearbox assemblies eliminate couplings, reduce inertia, and improve dynamic response | Separate motor and gearbox require couplings, adding inertia and alignment issues |

| Lubrication | Lubricated for life, no re‑greasing required | Periodic lubrication intervals increase downtime |

| Ingress Protection | IP65+ sealing, corrosion‑resistant options for washdown | Lower IP ratings; additional guarding often required |

| Noise / Vibration | Helical gearing for smooth, quiet operation | Straight‑cut gears with higher noise and vibration levels |

| Rigidity | High torsional rigidity for maintaining positional accuracy under load | Lower rigidity can cause deflection and loss of accuracy |

| Load Capacity | Optimized bearing arrangements for high radial and axial loads | Standard bearings with reduced load ratings |

| Delivery Time | Most configurations ship within 24 hours | Lead times often measured in weeks |

| Support | U.S.‑based engineering and application support | Limited local engineering resources |

Customer Testimonial

NEWS FROM STOBER

Gearbox noise reduction: Causes, fixes & best practices

Reduce gearbox noise by fixing root causes like gear mesh issues, poor lubrication, misalignment, and vibration so drives run smoother, quieter, and longer….

How to find information about an old STOBER unit or

Looking for details on an old STOBER unit or inventory item? Use the STOBER Product ID Tool to instantly access installation guides, technical specs, and…

Year in review: Top blog posts of 2025

Discover STOBER’s most-read blogs of 2025—from maintenance tips to success stories. Catch up on the insights that shaped the year before 2026 begins!…