Servo Motor Safety Brake

STOBER’s servo gear units can be paired with our ServoStop, an integrated safety brake. It’s ideal for vertical applications and provides redundant braking. It prevents slipping or falls, even when the motor is removed.

As the manufacturer of the world’s toughest gear boxes, you can count on us to equip servo motors with brakes that deliver the highest levels of performance and reliability. Units featuring this servo safety brake perform critical functions across a number of industries, including automotive manufacturing and aerospace. Our in-house expertise and history of innovation mean we can design fully customized solutions for your particular applications, as well.

The ServoStop external servo motor brake provides dynamic braking during power failures or emergencies, helping your operations achieve maximum safety conditions. It fits all standard servo motors and allows for dismounting of the motor even while it is engaged, meaning installation and maintenance is as simple and convenient as it can be. Our servo motor holding brake meets the EN ISO 13849 safety standard, so you can feel secure about adding it to your equipment. This unit also is available with manual hand release.

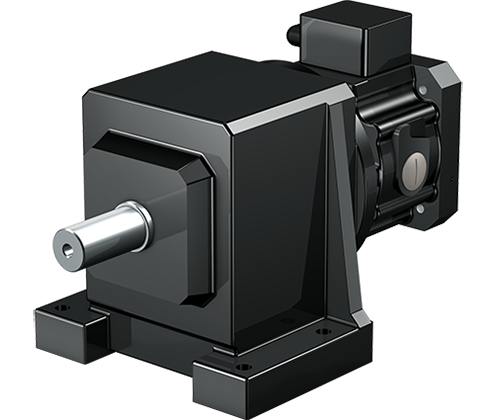

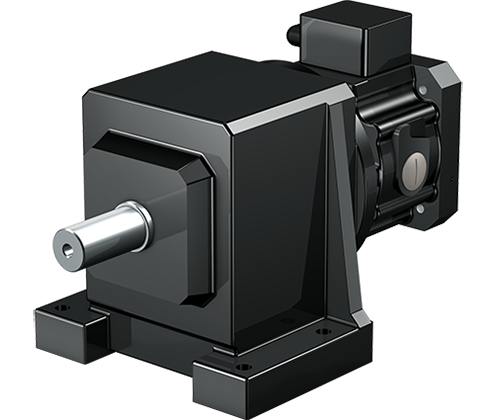

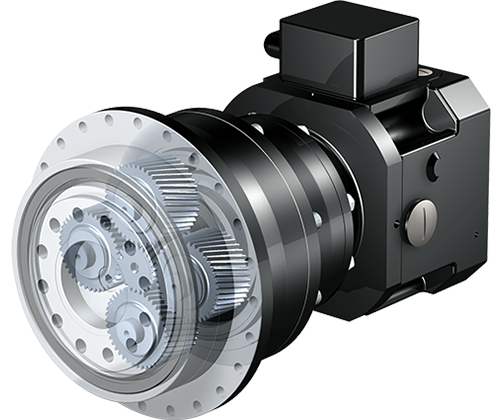

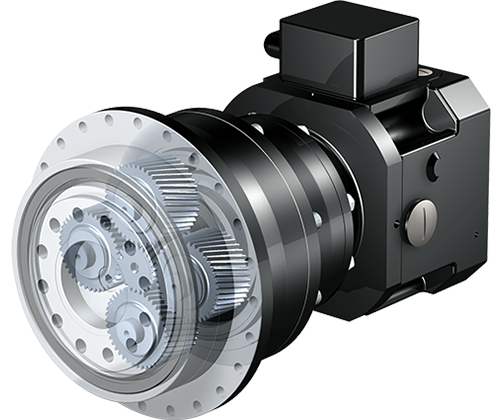

The C series can be integrated with a ServoStop safety brake. This series utilizes helical gearing for up to 97% efficiency.

Choose the housing style that fits your application – round or square flanges, tapped holes, or foot mounting.

C Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 47 – 4,800 Nm

- Nominal Brake Torque: 8 – 160 Nm

- Ratio: 2 – 70

- Backlash: 10 – 20 arcmin

- Efficiency: 97%

C Series: FEATURES

- Housing Styles:

- Round output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Square output flange

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

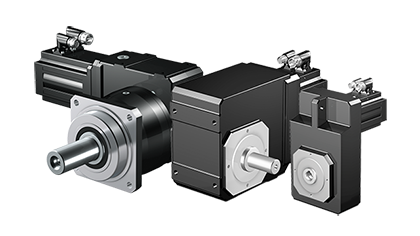

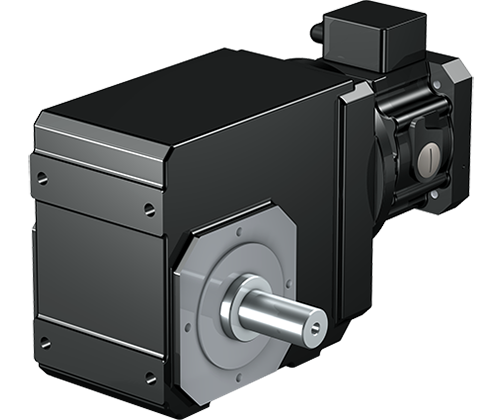

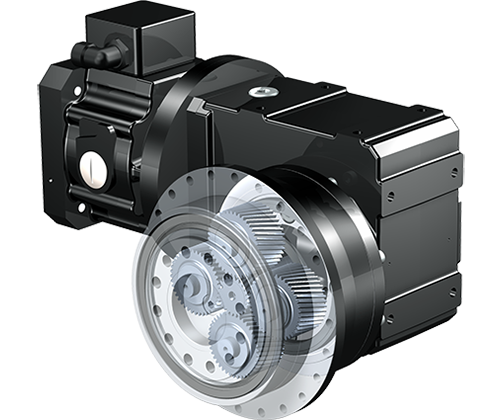

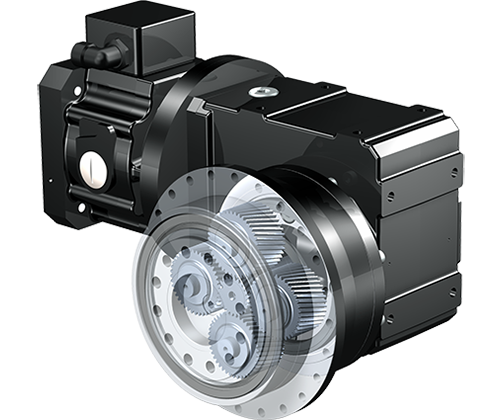

The F series can be integrated with a ServoStop safety brake. This series offers compact size and flexibility, as well as optimal efficiency due to the helical bevel gearing. Choose from a variety of housing styles and output options.

F Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 100 – 1,100 Nm

- Nominal Brake Torque: 8 – 160 Nm

- Ratio: 4.3 – 140

- Backlash: 5 – 11 arcmin

- Efficiency: 97%

F Series: FEATURES

- Outputs:

- Hollow bore

- Shaft

- Shrink ring

- Single or double wobble free bushing

- Housing Styles:

- Output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

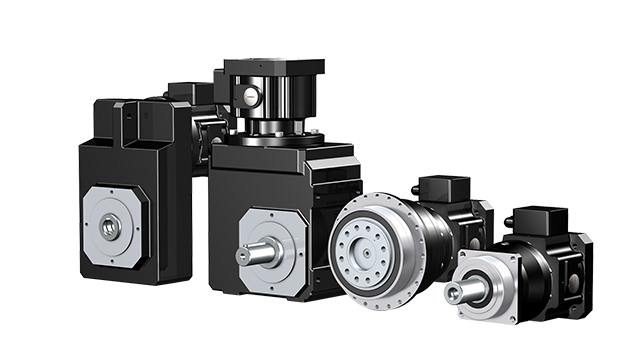

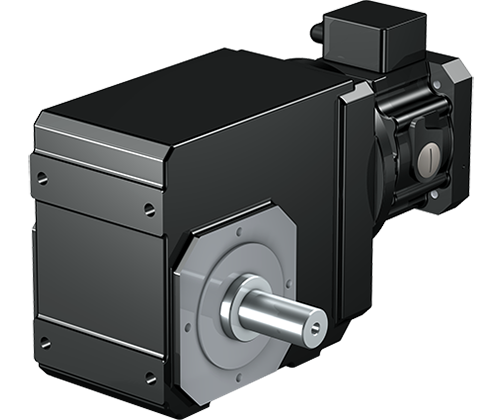

The K series can be integrated with a ServoStop safety brake. This series is unparalleled when it comes to right angle options. Its unique design allows you to use a variety of outputs, including shaft, hollow bore, shrink rings, and bushings.

Housing options include flange, feet, and torque arm

The K unit features helical bevel gearing, providing smooth motion and optimal efficiency.

K/KL Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 93 – 7,700 Nm

- Nominal Brake Torque: 8 – 160 Nm

- Ratio: 4 – 99

- Backlash: 1.5 – 12 arcmin

- Efficiency: 96 – 97%

K/KL Series: FEATURES

- Outputs:

- Hollow bore

- Shaft output

- Single or double wobble free bushing

- Housing Styles:

- Round Output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Torque arm bracket

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

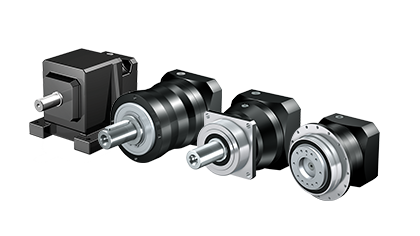

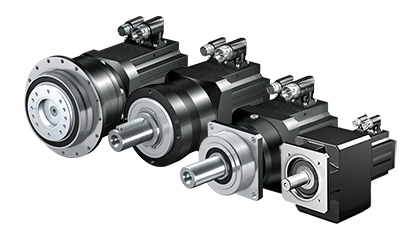

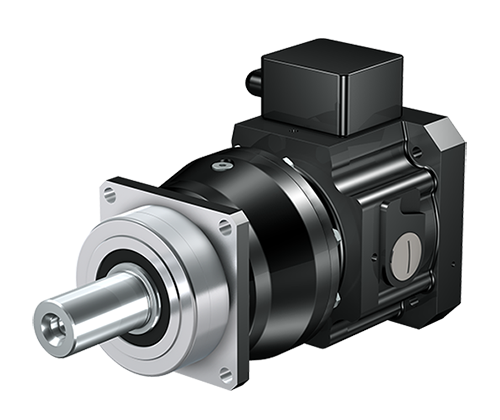

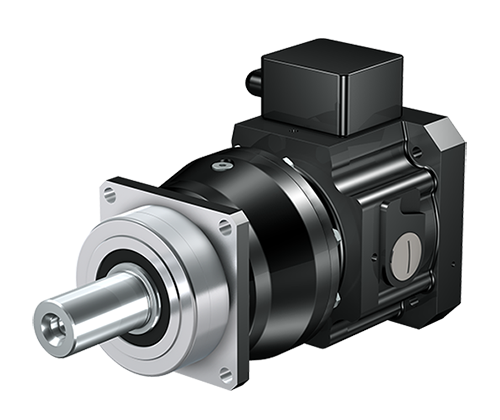

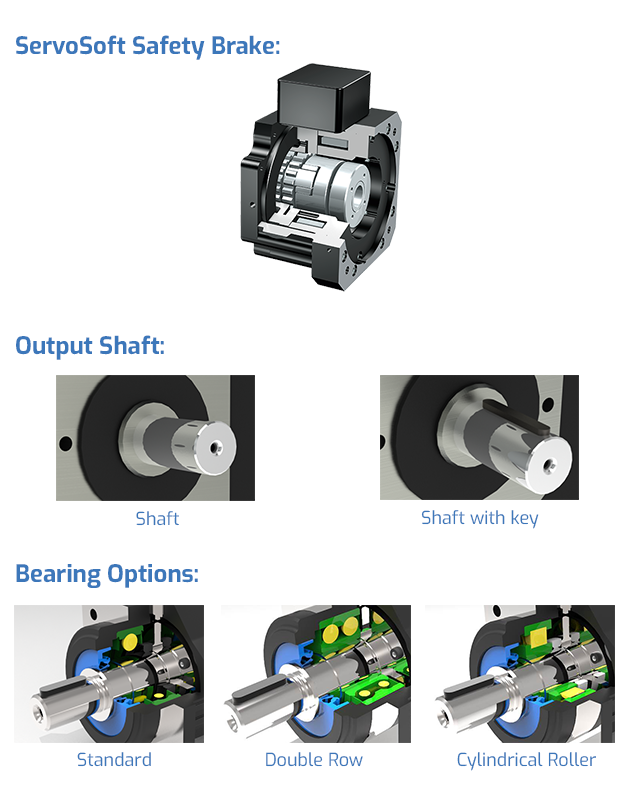

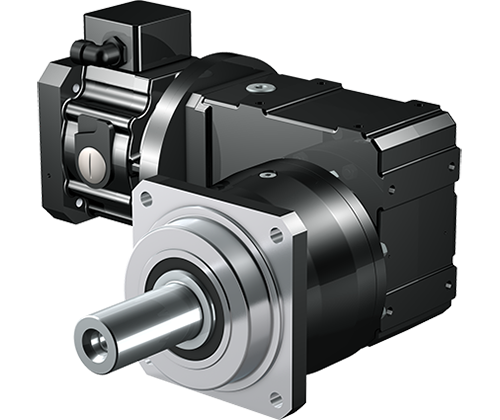

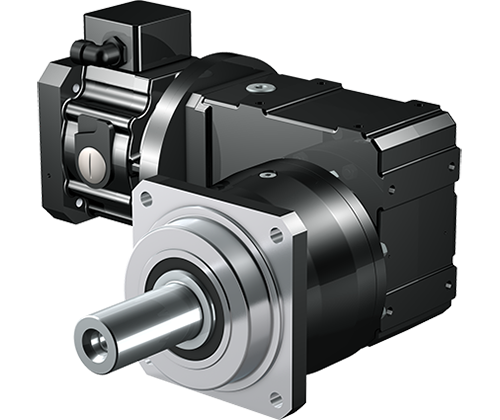

The P series can be integrated with a ServoStop safety brake. This series features planetary gearing, providing unsurpassed smoothness and precision.

It is incredibly efficient, has low backlash, and runs quiet.

Plus, you can choose from several bearing options to handle radial or axial loads, optimizing your machine design.

P Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 109 – 3,000 Nm

- Nominal Brake Torque: 8 – 300 Nm

- Ratio: 3 – 80

- Backlash: 3 – 4 arcmin

- Efficiency: 95 – 97%

P Series: FEATURES

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty - 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

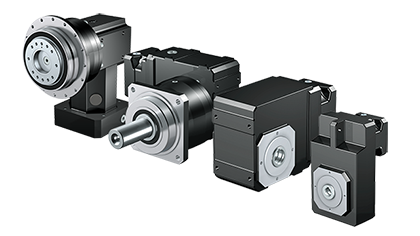

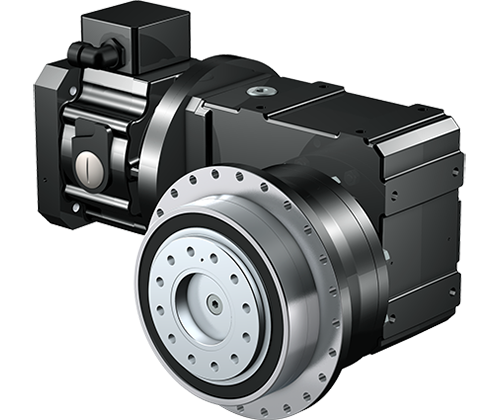

The PH series can be integrated with a ServoStop safety brake. This series offers superior stiffness and accuracy.

It offers a reinforced bearing option for applications with higher axial loads.

PH Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 144 – 7,500 Nm

- Nominal Brake Torque: 8 – 300 Nm

- Ratio: 4 – 121

- Backlash: 3 arcmin

- Efficiency: 90 – 96%

PH Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard Duty - RAL-9005 black paint

- Washdown Duty - 316 stainless steel epoxy paint

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

The PHK series can be integrated with a ServoStop safety brake. This series combines our planetary PH series with a K series input.

This gear unit features quiet operation, higher ratios, and higher input speeds compared to a KX series unit.

PHK Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 320 – 7,500 Nm

- Nominal Brake Torque: 8 – 160 Nm

- Ratio: 16 – 466

- Backlash: 3.5 – 4.5 arcmin

- Efficiency: 92 – 93%

PHK Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Coating Options: options for different environments.

- Standard Duty - RAL-9005 black paint

- Washdown Duty - 316 stainless steel epoxy paint

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

The PHQ can be integrated with a ServoStop safety brake. The PHQ series features four planetary gears, making it the most powerful gearbox on the market.

It provides smooth operation while producing huge amounts of torque.

PHQ Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 767 – 22,000 Nm

- Nominal Brake Torque: 8 – 300 Nm

- Ratio: 18 – 420

- Backlash: 3 arcmin

- Efficiency: 90 -93%

PHQ Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard Duty - RAL-9005 black paint

- Washdown Duty - 316 stainless steel epoxy paint

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

The PHQK can be integrated with a ServoStop safety brake. This series series combines our planetary PHQ series with a K series input.

This gear unit features the highest acceleration torque and torque density.

PHQK Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 425 – 43,000 Nm

- Nominal Brake Torque: 8 – 160 Nm

- Ratio: 22 – 591

- Backlash: 3.5 – 4 arcmin

- Efficiency: 92 – 93%

PHQK Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Coating Options: options for different environments.

- Standard Duty - RAL-9005 black paint

- Washdown Duty - 316 stainless steel epoxy paint

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

The PK series can be integrated with a ServoStop safety brake. This series combines our planetary P series with a K series input.

This gear unit offers quieter operation, higher input speeds, and higher ratios compared to a KX unit.

PK Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Torque: 200 – 2,700 Nm

- Nominal Brake Torque: 8 – 100 Nm

- Ratio: 12 – 390

- Backlash: 3.5 – 5 arcmin

- Efficiency: 94%

PK Series: FEATURES

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty - 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Input Voltage:

- 24V

- 104V

- Rectifier – convert AC voltage into DC Voltage

- Only required for 104 Volts

- Manual Release:

- Available with manual hand release

- Connection Type for Power Source:

- Terminal box – for hard wiring

- Connector – for cable connection

- Air Gap Monitoring:

- With proximity switch IP54

- With proximity switch IP65

STOBER’s SMS Gearboxes

STOBER’s Generation 3 Planetary

| Title | Version | ID | Date | Language | Size | |

| Catalog Synchronous servo geared motors with redundant brake | 01 | 443311 | 2023 04 | EN | 18.29 MB |

| Catalog ServoStop servo gear units with brake | 02 | 443234 | 2023 04 | EN | 15.15 MB |

| Title | Version | ID | Date | Language | Size | |

| Operating manual MB23 - MB53 ServoStop Motor adapter with brake | 03 | 443287 | 2024 01 | EN | 6.39 MB |

| Manual ServoStop Installation | 30 | 442800 | 2021 09 | EN | 221.31 KB |