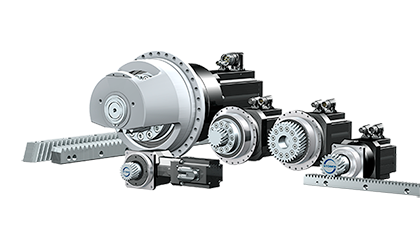

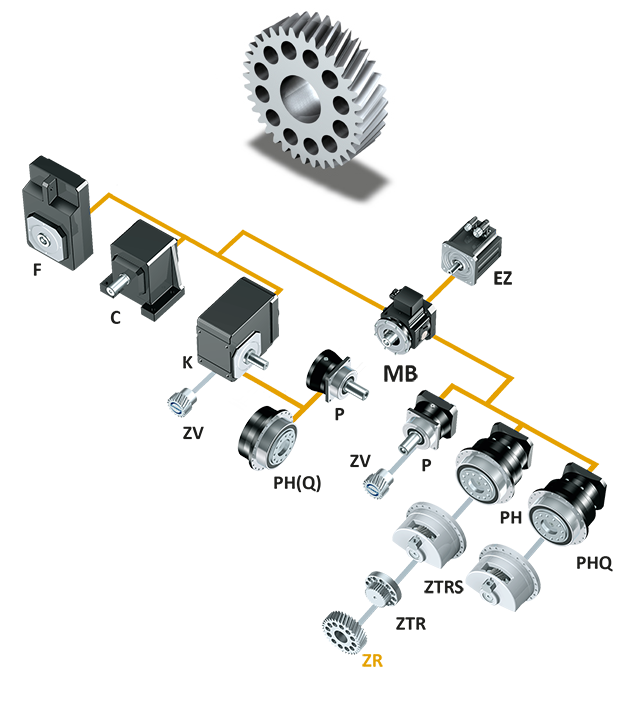

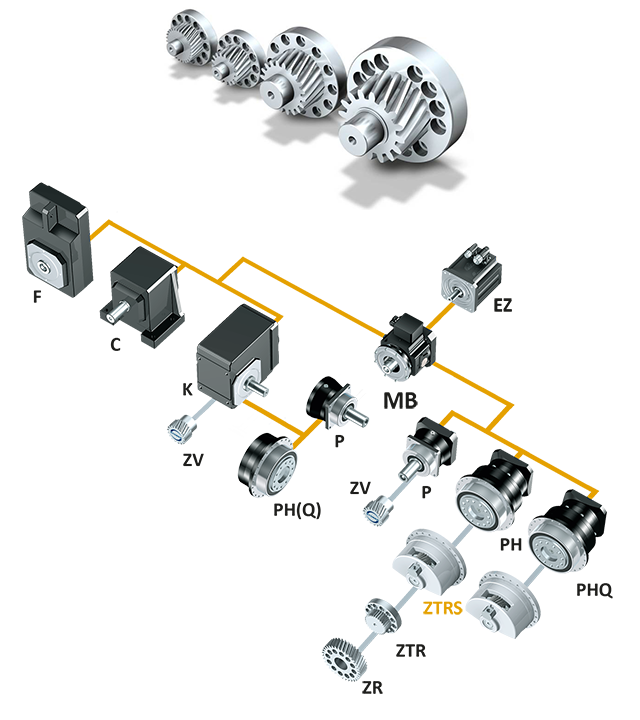

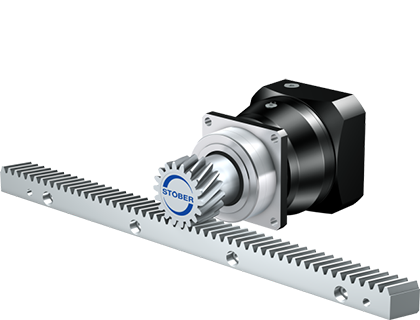

Rack and Pinion Drive Sytems

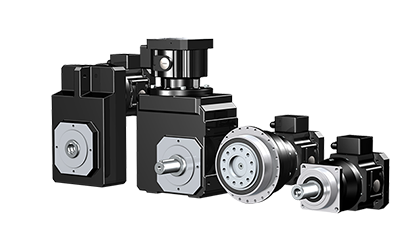

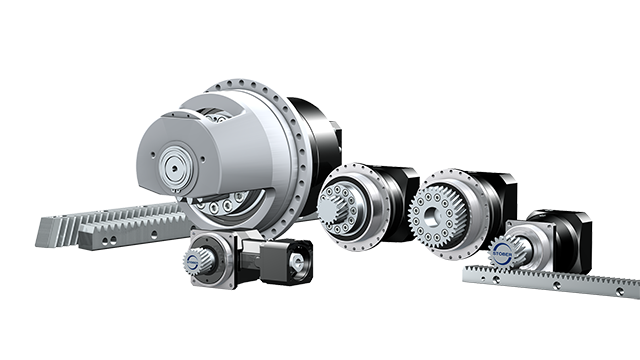

From high speed to high force, flange to shaft, STOBER has the options you need, especially when it comes to rack and pinion drives. Every rack and pinion system uses STOBER’s superior servo gear units and can be made into a system with a motor. These pinions work with a variety of rack options, including helical or straight tooth.

The versatility of our rack and pinion drive systems makes them indispensable across a broad spectrum of industries. Examples of our products can be found in the packaging, beverage, food processing, automotive, printing, and material handling sectors, among others. All of our rack and pinion drive systems are available as compact servo or geared motors, adding to their adaptability. Additionally, they can be mounted to any motor featuring our tolerance motor adapter. If our standard systems don’t fit exactly into a customer’s existing setup, we also have the capability to design customized solutions that will.

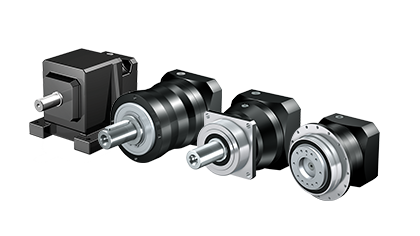

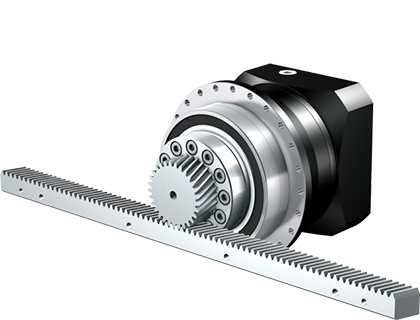

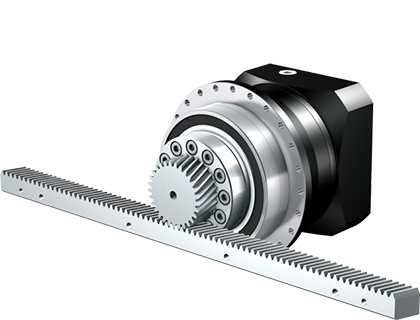

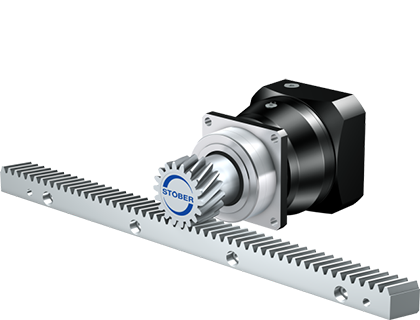

The ZR series is ideal for high-speed applications. The large helical pinion mates to the rack for high feed rates. It is attached to the PH series and works well for bridging larger distances between axes.

ZR units are available as compact servo or geared motors, or they can be mounted to any motor with our toleranced motor adapter.

ZR Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Feed Force: 2.1- 15 kN

- Feed Velocity: .23 – 6.7 meters/second

- Module: 2 – 4 mm

- Number of teeth: 26 – 45

- Backlash: 10 – 56 μm

ZR Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Available with a geared motor

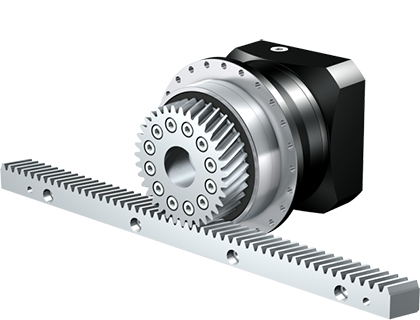

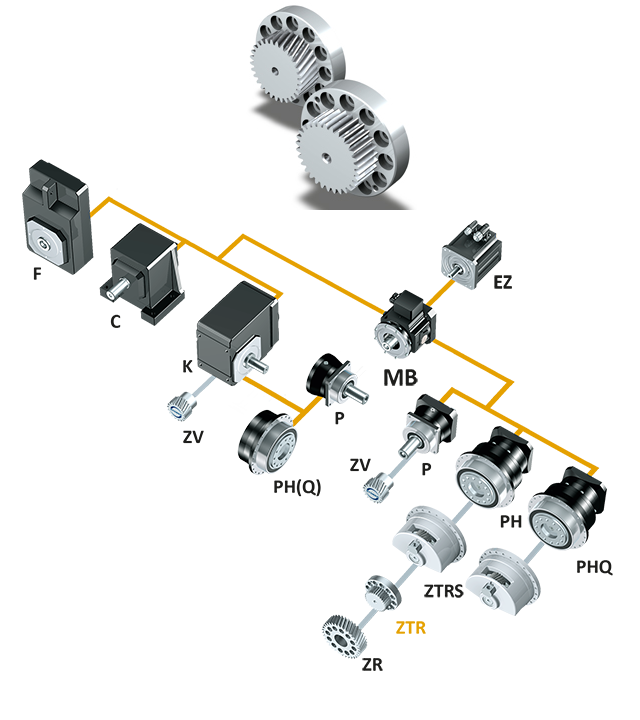

The ZTR series is perfect for applications that require high force but have smaller machine envelopes. It attaches to the PH series and works well for machine tool feed axes.

ZTR gear units are available as compact servo or geared motors, or they can be mounted to any motor with our toleranced motor adapter.

ZTR Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Feed Force: 5.8 – 67 kN

- Feed Velocity: .09 – 4.7 meters/second

- Module: 2 – 8 mm

- Number of teeth: 12 – 32

- Backlash: 4 – 44 μm

ZTR Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Available with a geared motor

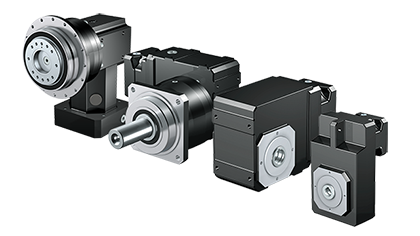

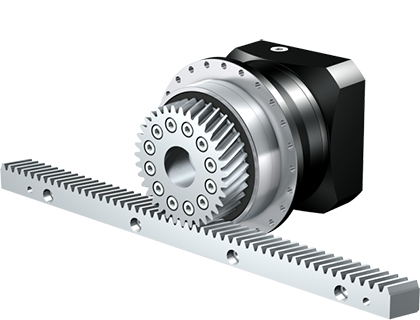

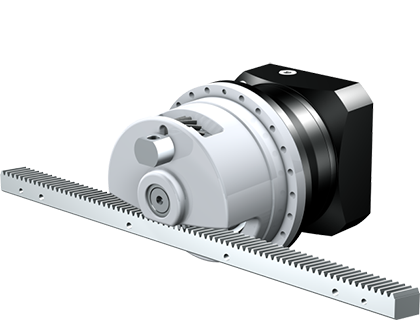

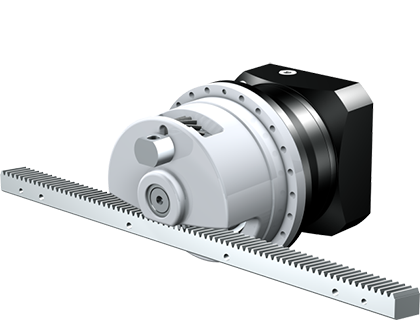

The ZTRS series is perfect for applications that require high force. It allows the machine to have optimal performance and stiffness. The bearing cover and felt gear provide additional force. It is attached to the PH_EZ series and works well for machine tool feed axes.

ZTRS gear units are available as compact servo or geared motors, or they can be mounted to any motor with our toleranced motor adapter.

ZTRS Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Feed Force: 16 – 126 kN

- Feed Velocity: .06 – 4.7 meters/second

- Module: 2 – 10 mm

- Number of teeth: 15 – 32

- Backlash: 7 – 70 μm

ZTRS Series: FEATURES

- Gear:

- Standard gear

- Felt gear – simplify lubrication

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Available with a geared motor

- Find your right fit!

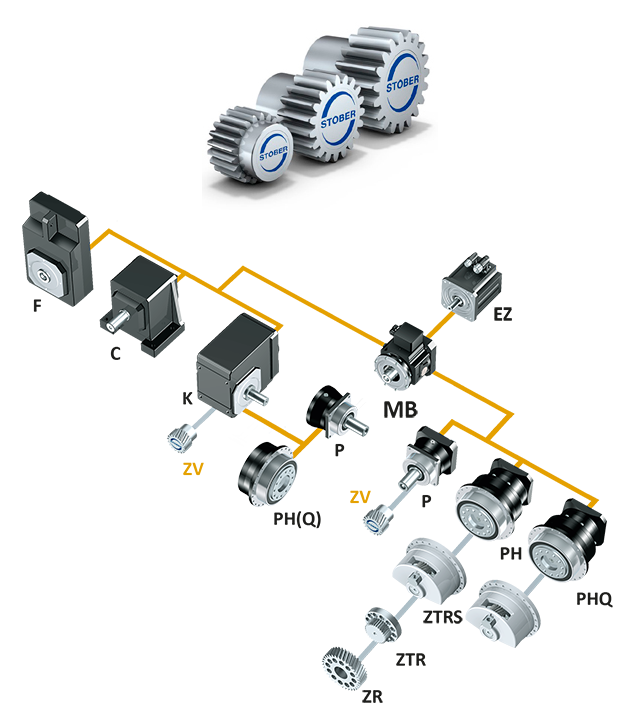

The ZV series can be paired with numerous STOBER gearboxes, giving you the freedom to have an inline or a right angle solution. It is ideal for general automation applications and offers great performance. It attaches to the P, PE, KS, K, and KL geared motor series.

ZV gear units are available as compact servo or geared motors, or they can be mounted to any motor with our toleranced motor adapter.

ZV Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Acceleration Feed Force: 1.3 – 15 kN

- Feed Velocity: .06 – 5.3 meters/second

- Module: 2 – 4 mm

- Number of teeth: 16 – 25

- Backlash: 8 – 123 μm

ZV Series: FEATURES

- ZV with P Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Pinion Position:

- ZV with PE Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Pinion Position:

- ZV with KS Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Pinion Position:

- ZV with K/KL Series

- Pinion Position:

- Shaft end

- Shaft shoulder

- Housing Style:

- Pitch circle diameter tapped holes

- Foot mounting

- Pinion Position:

- Available as a geared motor!

STOBER Rack and Pinion

STOBER Configurator

| Title | Version | ID | Date | Language | Size | |

| Catalog rack and pinion drives | 05 | 443137 | 2023 04 | EN | 8.78 MB |

| Title | Version | ID | Date | Language | Size | |

| Lubricant fill volume | 17 | 441871 | 2023 10 | EN | 2.18 MB |

| Manual Gear Units Installation and Troubleshooting | 30 | 442900 | 2021 09 | EN | 16.36 MB |