No Maintenance NEMA Gearboxes

STOBER’s NEMA gearboxes require no maintenance. No oil leaks, no rust, and no water ingress. Every NEMA gear unit is assembled at our Maysville, Ky. facility, backed by a three-year warranty, and delivered fast – one-day shipping! These gear units are tough – in fact, we make the world’s toughest gearbox.

Our ability to design fully customized solutions make us the most versatile manufacturer of NEMA gearboxes. We’ve supplied units to customers in industries including automotive manufacturing, beverage production, printing, food processing, material handling, packaging, and more. No matter what the application, our products are designed to provide the highest degree of resiliency and durability. This makes them perfect for challenging environments and conditions, including harsh washdowns and intensive cleaning. At the same time, our NEMA gear units also deliver the superior performance that can revolutionize how well equipment functions across numerous processes.

The KSS series is the world’s toughest gearbox.

It is made from stainless steel and electropolished to create a product that can withstand the harshest cleaning.

No maintenance, no water ingress, no oil leaks.

KSS Series: TECHNICAL DATA

|

$

|

$

|

$

|

$

|

$

|

- Total gear ratio range: 4 – 272

- Output torque: 364 – 4,872 lb in

- Efficiency: Up to 97%

- Overhung Load Capacity: Up to 2,520 lbs.

KSS Series: FEATURES

- Outputs:

- Hollow bore

- Shaft output

- Double wobble free bushing

- Housing Styles:

- Output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Torque arm bracket

- Motor Adapter:

- MSR – standard clamp coupling

- Mounting Positions:

- EL1256 (Any horizontal output position)

- E34

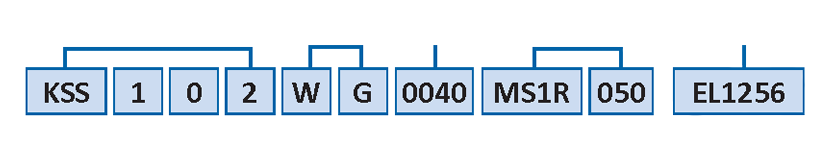

KSS Series: PART NUMBER EXAMPLE:

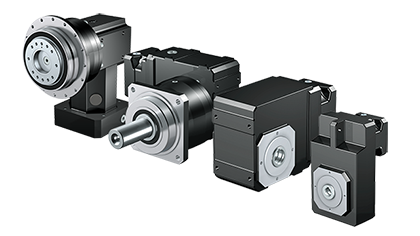

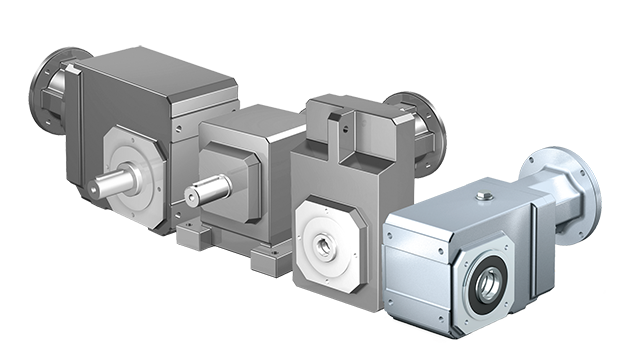

The K/KL series is the ultimate solution for right angle applications.

With its unique helical bevel gearing, you achieve unparalleled performance, efficiency, and lifetime. It is 98.5% efficient per stage of gearing.

Choose the output and housing style that fits your application.

Output options include hollow bore, shaft, and bushing. Housing styles include torque arm, foot mounting, flange, and tapped holes.

K Series: TECHNICAL DATA

|

$

|

$

|

$

|

$

|

$

|

- Total gear ratio range: 4 – 381

- Output torque: 298 – 94,002 lb in

- Efficiency: Up to 97%

- Overhung Load Capacity: Up to 18,000 lbs.

K Series: FEATURES

- Outputs:

- Hollow bore

- Shaft output (K)

- Shaft with or without key (KL)

- Single or double wobble free bushing

- Housing Styles:

- Output flange (Round for K, Square for KL)

- Pitch circle diameter tapped holes

- Foot mounting

- Torque arm bracket

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty – RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty – 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty – 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- MLR – standard clamp coupling for KL

- MR – standard clamp coupling for K

- Mounting Positions:

- Standard Duty – EL1, 2, 3, 4, 5, or 6

- Corrosion Resistant or Food Duty – EL1256 (Any horizontal output)

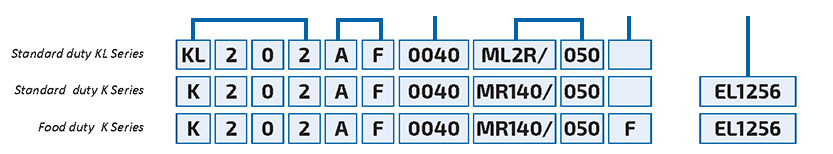

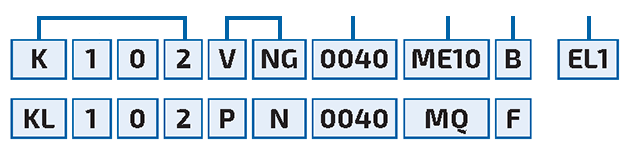

K/KL Series: PART NUMBER EXAMPLE:

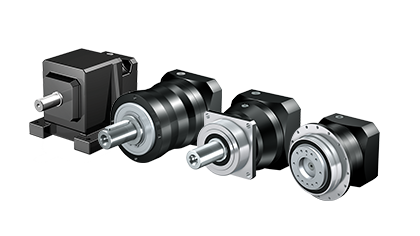

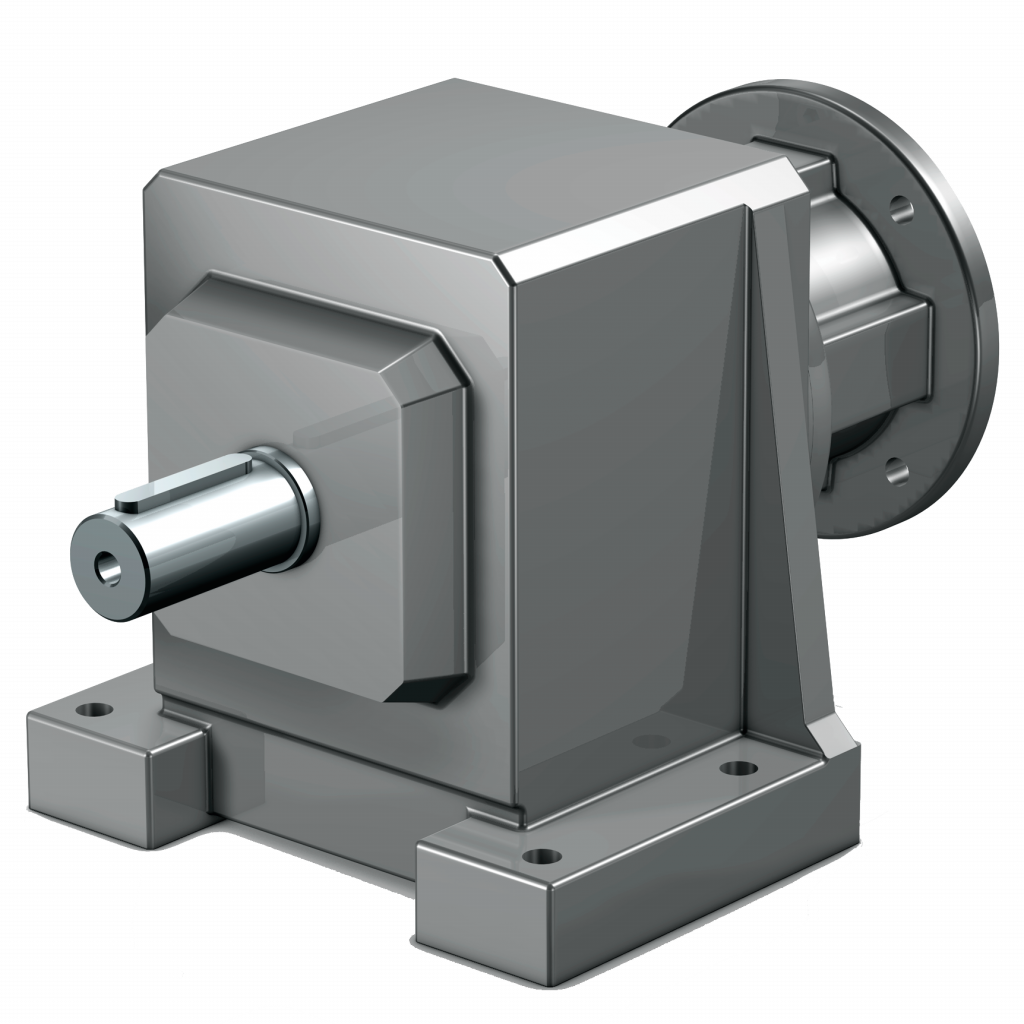

The C series utilizes helical gearing for up to 97% efficiency.

Choose the housing style that fits your application – round or square flanges, tapped holes, or foot mounting.

C Series: TECHNICAL DATA

|

$

|

$

|

$

|

$

|

$

|

- Total gear ratio range: 2 – 276

- Output torque: 182 – 53,148 lb in

- Efficiency: Up to 97%

- Overhung Load Capacity: Up to 8,325 lbs.

C Series: FEATURES

- Outputs:

- Shaft with key

- Housing Styles:

- Round output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Square output flange

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty – RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty – 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty – 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- MR – standard clamp coupling

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Corrosion Resistant or Food Duty – EL1234 (Any horizontal output)

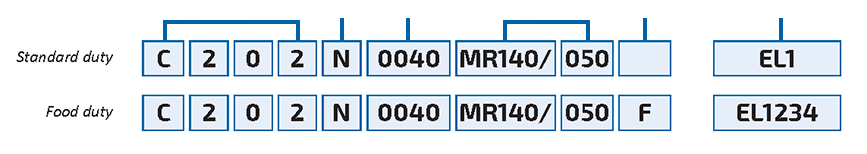

C Series: PART NUMBER EXAMPLE:

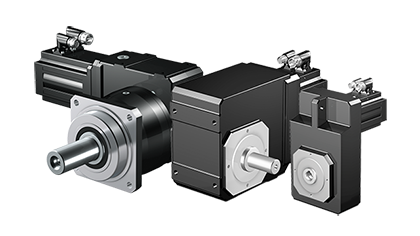

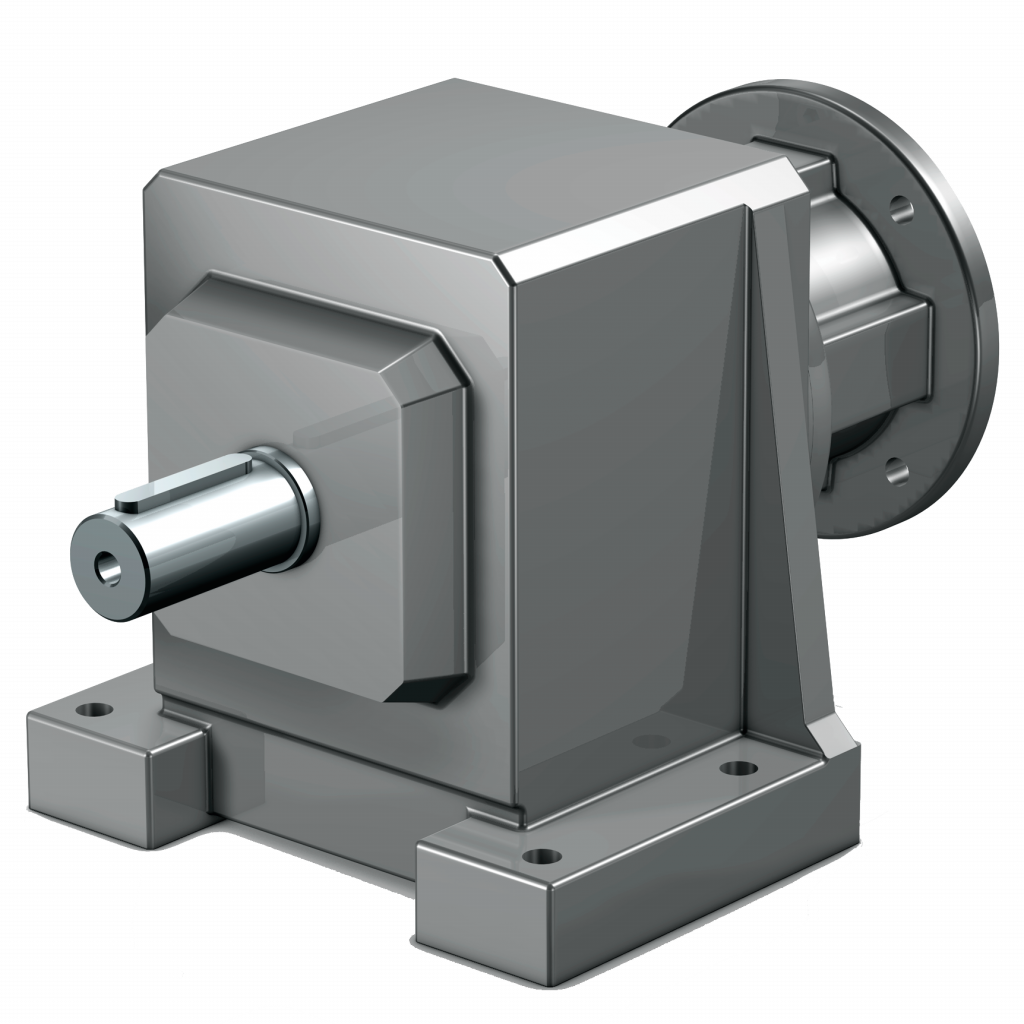

The F series utilizes helical gearing for up to 97% efficiency.

Choose the output and housing style that fits your application. Outputs include hollow bore, solid shaft, or bushing, and mounting styles include round flanges, tapped holes, or foot mounting.

F Series: TECHNICAL DATA

|

$

|

$

|

$

|

$

|

$

|

- Total gear ratio range: 4 – 552

- Output torque: 392 – 9,744 lb in

- Efficiency: Up to 97%

- Overhung Load Capacity: Up to 2,813 lbs.

F Series: FEATURES

- Outputs:

- Hollow bore

- Shaft

- Single or double wobble free bushing

- Housing Styles:

- Output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty – RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty – 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty – 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- MR – standard clamp coupling

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Corrosion Resistant or Food Duty – EL1234 (Any horizontal output)

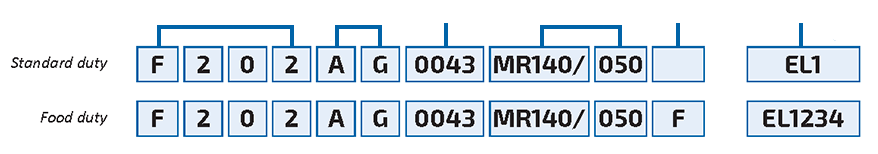

F Series: PART NUMBER EXAMPLE:

| Title | Version | ID | Date | Language | Size | |

| MGS Speed Reducers | 31 | 442933 | 2023 02 | EN | 19.59 MB |

| MGS Speed Reducers C Ratings | 31 | 442933 | 2023 02 | EN | 1.32 MB |

| MGS Speed Reducers C Dimensions | 31 | 442933 | 2022 05 | EN | 597.62 KB |

| MGS Speed Reducers K Ratings | 31 | 442933 | 2022 05 | EN | 1.88 MB |

| MGS Speed Reducers KSS Ratings | 31 | 442933 | 2022 05 | EN | 1.75 MB |

| MGS Speed Reducers KSS Dimensions | 31 | 442933 | 2022 05 | EN | 806.48 KB |

| MGS Speed Reducers F Ratings | 31 | 442933 | 2022 05 | EN | 992.79 KB |

| MGS Speed Reducers F Dimensions | 31 | 442933 | 2022 05 | EN | 693.91 KB |

| MGS Speed Reducers K Dimensions | 31 | 442933 | 2022 05 | EN | 1.50 MB |