When you’re looking for a gearbox, choose the most environmentally friendly gearbox on the market! STOBER KSS features an all-stainless steel housing and output, meaning it can handle the harshest washdowns.

STOBER gearboxes don’t require maintenance and don’t leak oil, so you can get rid of your oil drip pans, stop replacing oil every six months, and don’t worry about disposing of used oil.

Not only will you save thousands in energy expenditures, you’ll also reduce heat in your workplace environment since STOBER KSS units are 97 percent efficient.

STOBER’s 3-year warranty means the gearboxes last–an average of 9.1 years!

And when you’re ready, STOBER’s renewal programs provide even more life out of your gearbox. The MR Adapter program allows you to replace the motor adapter and keep the gearbox or the KSS Renewal program allows the stainless steel housing to be reused and its components replaced with new.

Want to know more about the environmentally friendly gearbox? Download the guide below!

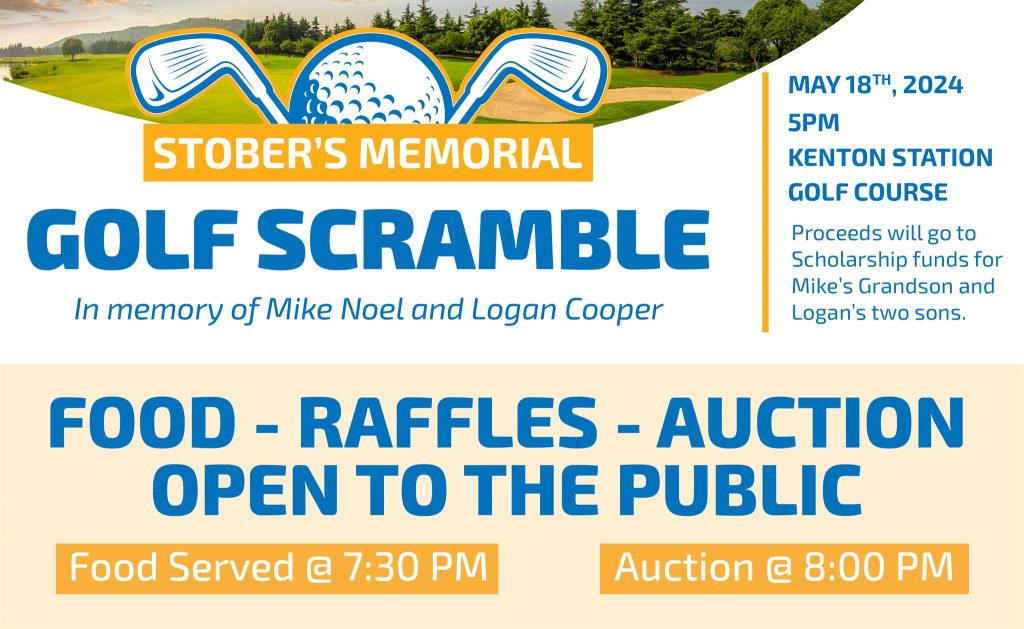

STOBER Memorial Golf Scramble to be held May 18

STOBER Memorial Golf Scramble to be held May 18  Happy Retirement, Billie Wallingford!

Happy Retirement, Billie Wallingford!  STOBER offers the ultimate solutions for the cheese industry

STOBER offers the ultimate solutions for the cheese industry  Most compact planetary geared motors just got better

Most compact planetary geared motors just got better